Device and method for detecting sealing property of sealing element

A sealing performance and detection device technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, etc., can solve the problems of inability to accurately measure the steam leakage of the seal, the leakage of the auxiliary sealing ring, etc., and achieve simple methods and accurate measurement results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

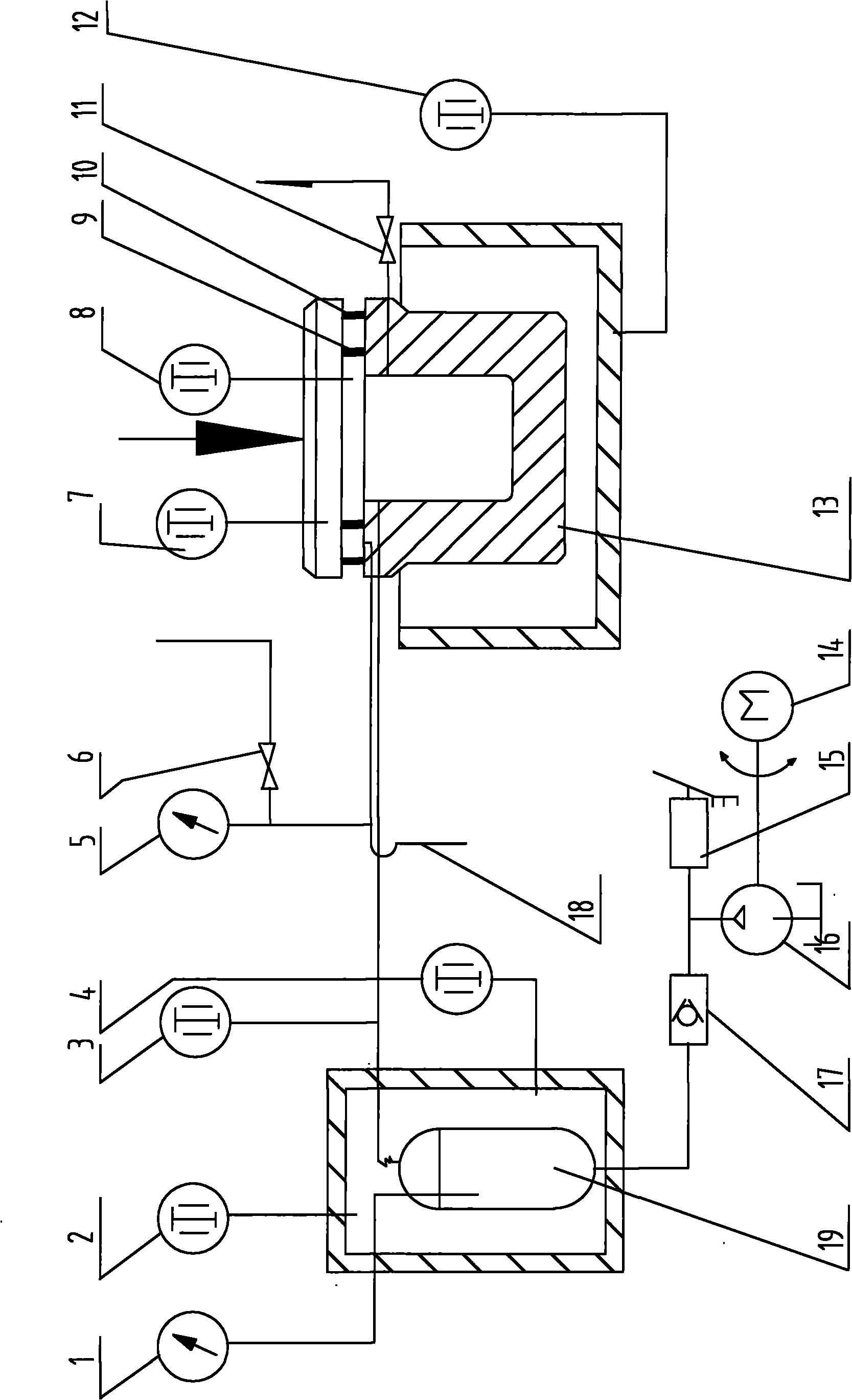

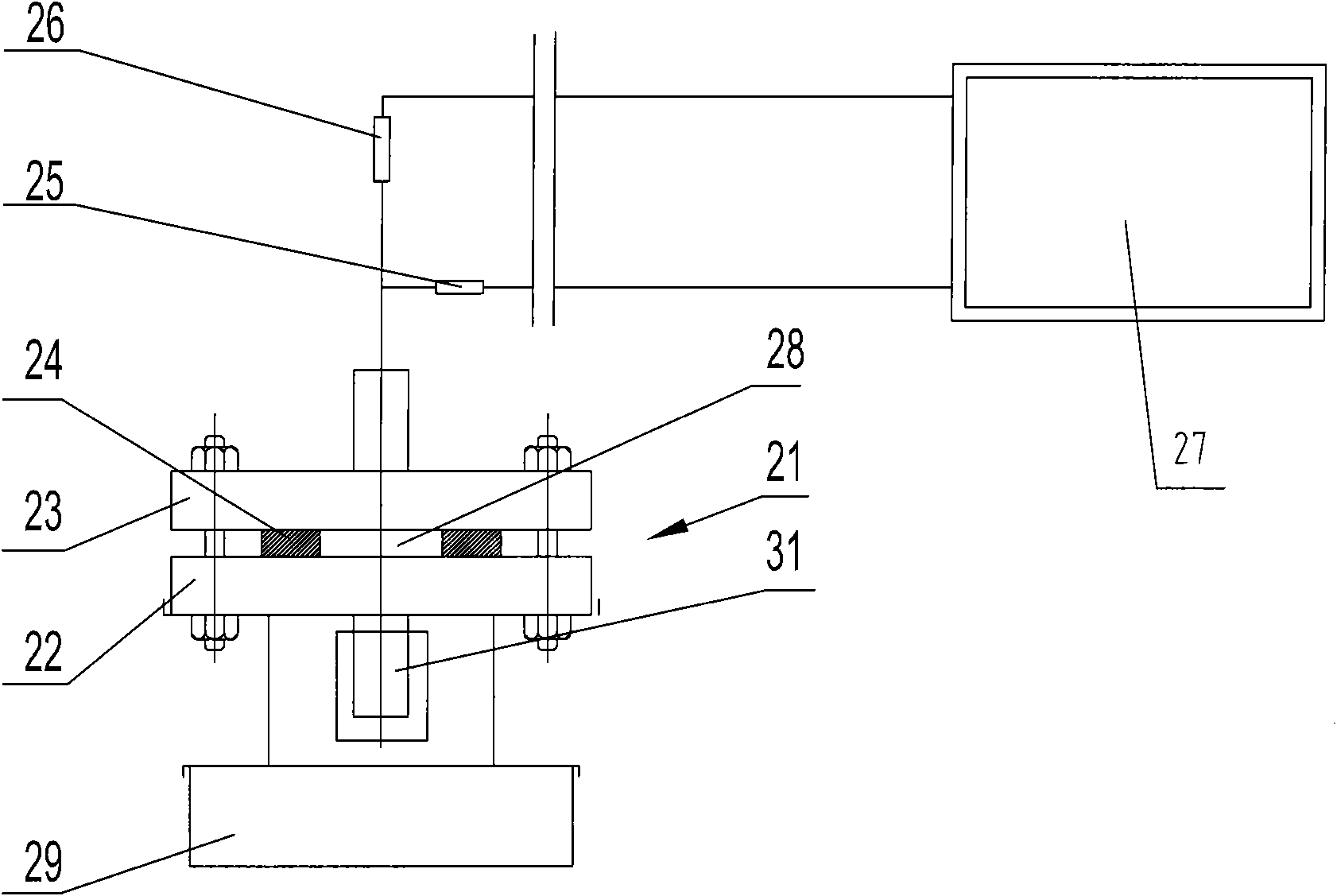

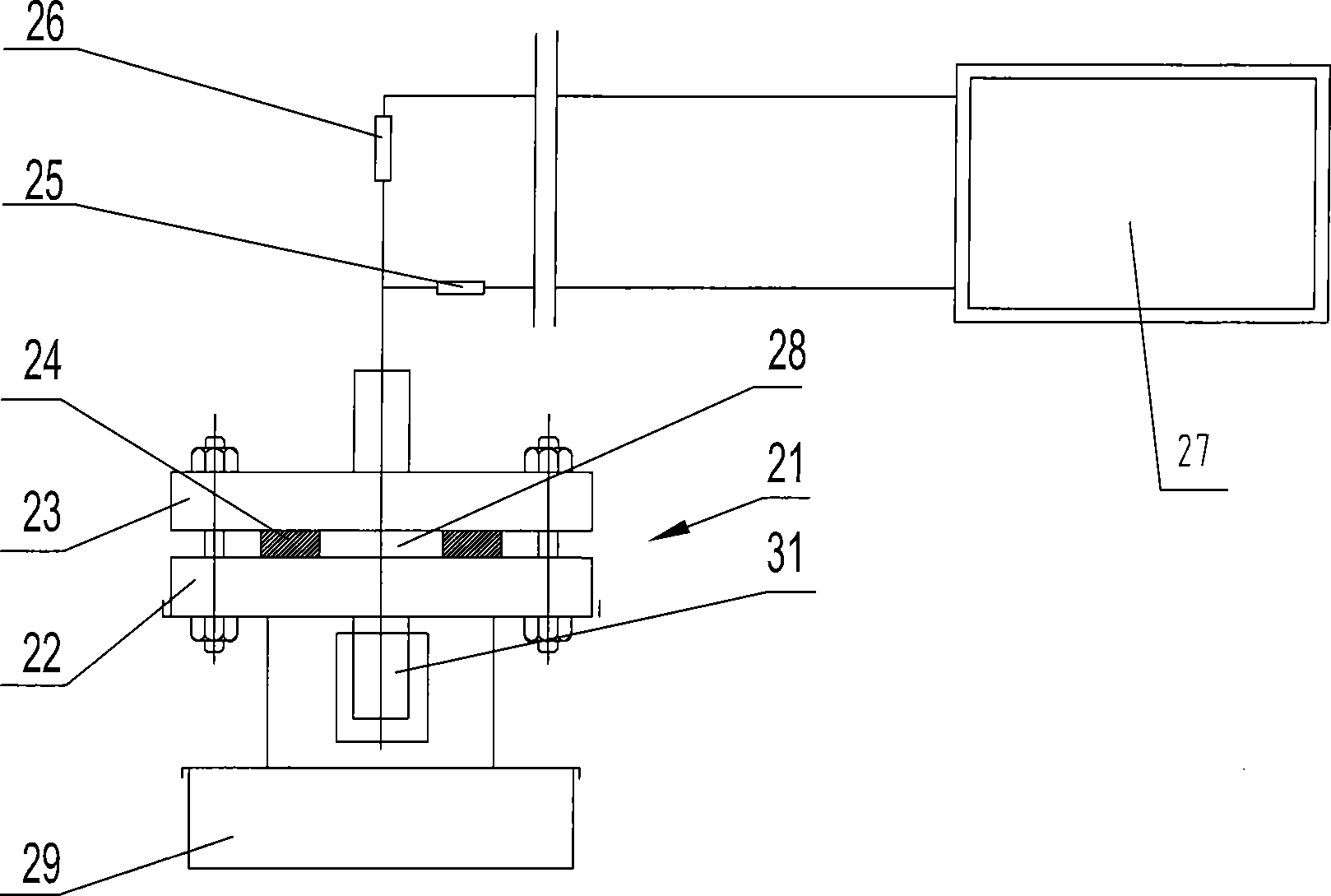

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. figure 2 The upper and lower positional relationships shown in are the same.

[0031] A device for detecting the sealing performance of a seal, which includes: a steam generating device 21, the steam generating device 21 includes a lower module 22 with an inner cavity, an upper module 23 arranged on the lower module 22, and the to-be-tested The seal 24 is loaded between the upper module 23 and the lower module 22, the upper module 23 and the lower module 22 are two connecting flanges, the lower module 22, the seal 24 to be tested and the upper A steam generation chamber 28 is enclosed between the modules 23, and the steam generation device 21 also includes a vent valve (not shown) for removing the air in the steam generation chamber 28;

[0032] The heater 31 is used to heat the liquid in the steam generating chamber 28;

[0033] A weighing device 29 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com