Method for measuring lubricating grease drop point

A grease and dropping point technology, applied in the investigation phase/state change and other directions, can solve the problems of poor data repeatability and large errors, and achieve accurate and reliable experimental basis, convenient operation and implementation, and better repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

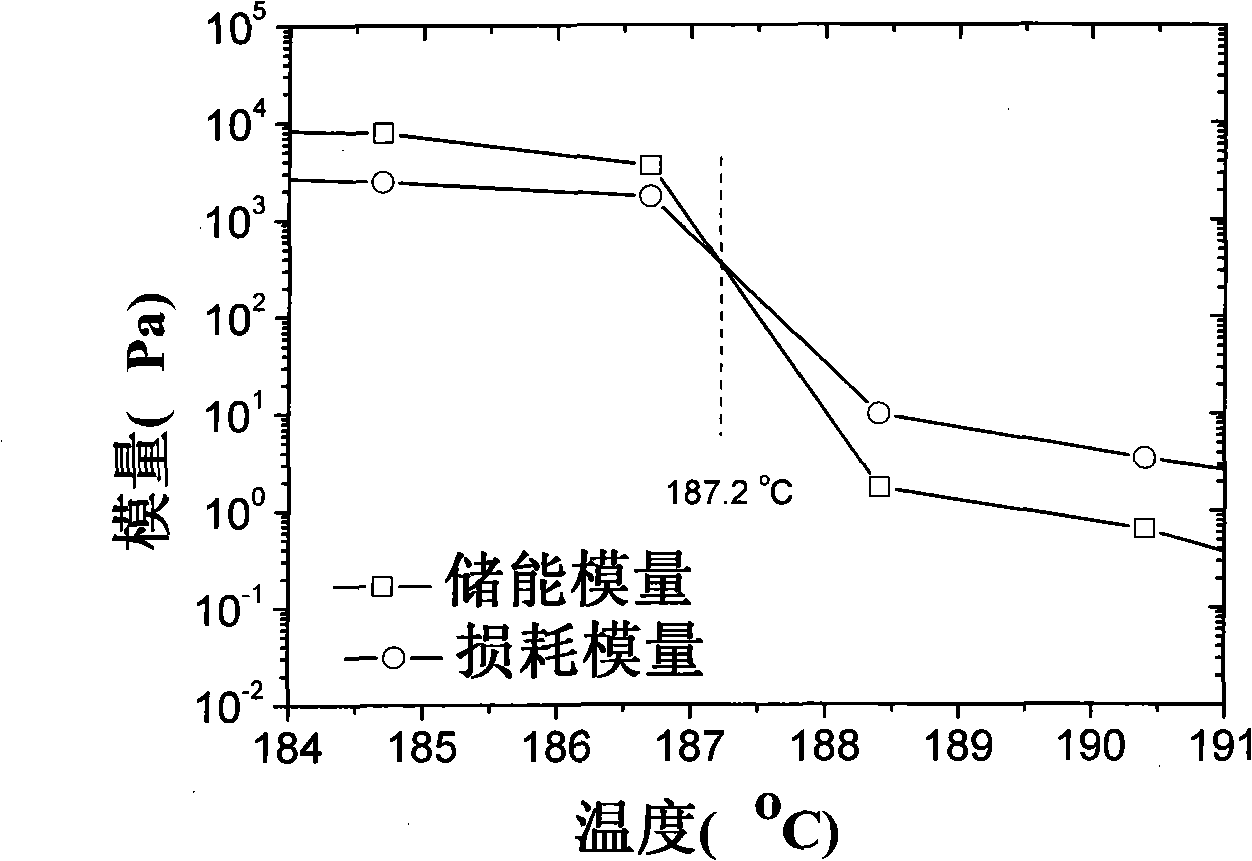

[0034] The grease sample used is "II-9TC Grease" produced by Tianjin Shixun Industry and Trade Co., Ltd., provided by Tianjin Chengke Transmission Electromechanical Technology Co., Ltd. Using the standard GB / T 4929 to measure the dropping point, the result is 190°C.

[0035] (1) Using a StressTech rotational rheometer, select a parallel plate accessory with a diameter of 20mm, add a semi-solid grease sample to the lower plate of the selected parallel plate at 25°C, and press down the parallel plate, Control the distance between the upper and lower plates to 1mm, remove excess samples around the upper and lower plates, and keep the samples just filled between the upper and lower plates;

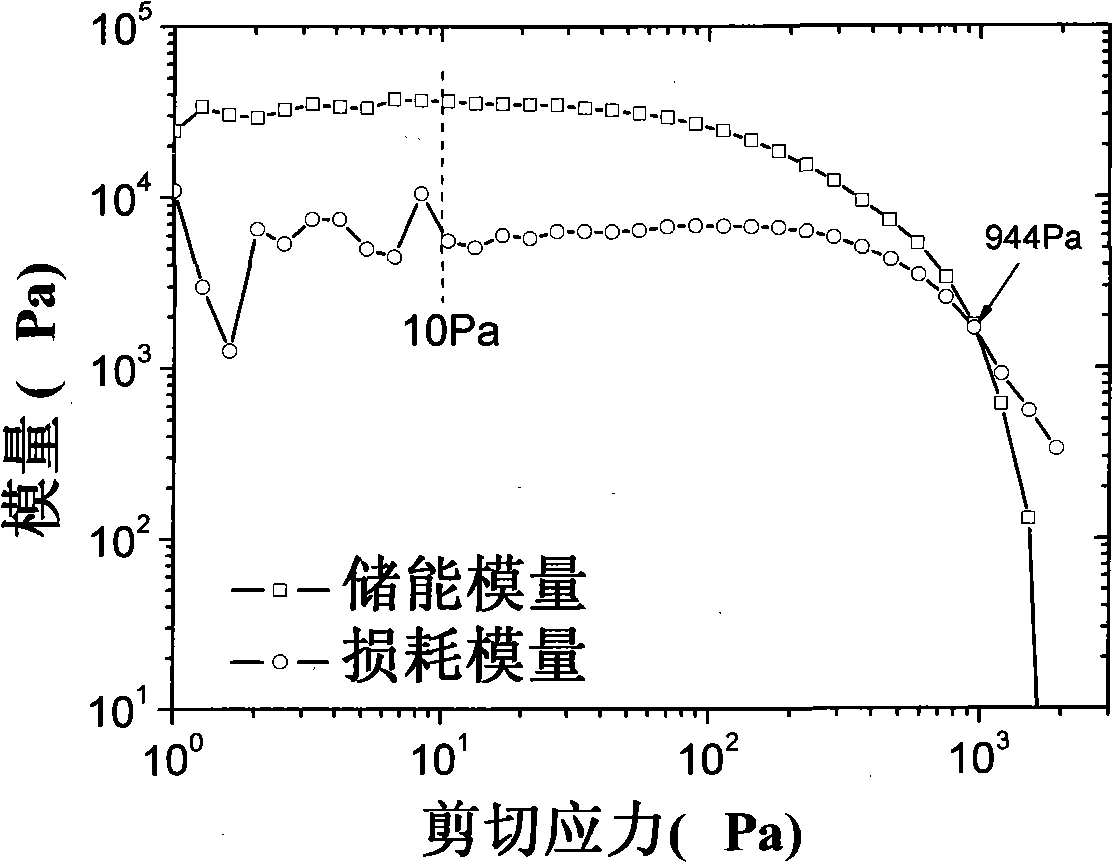

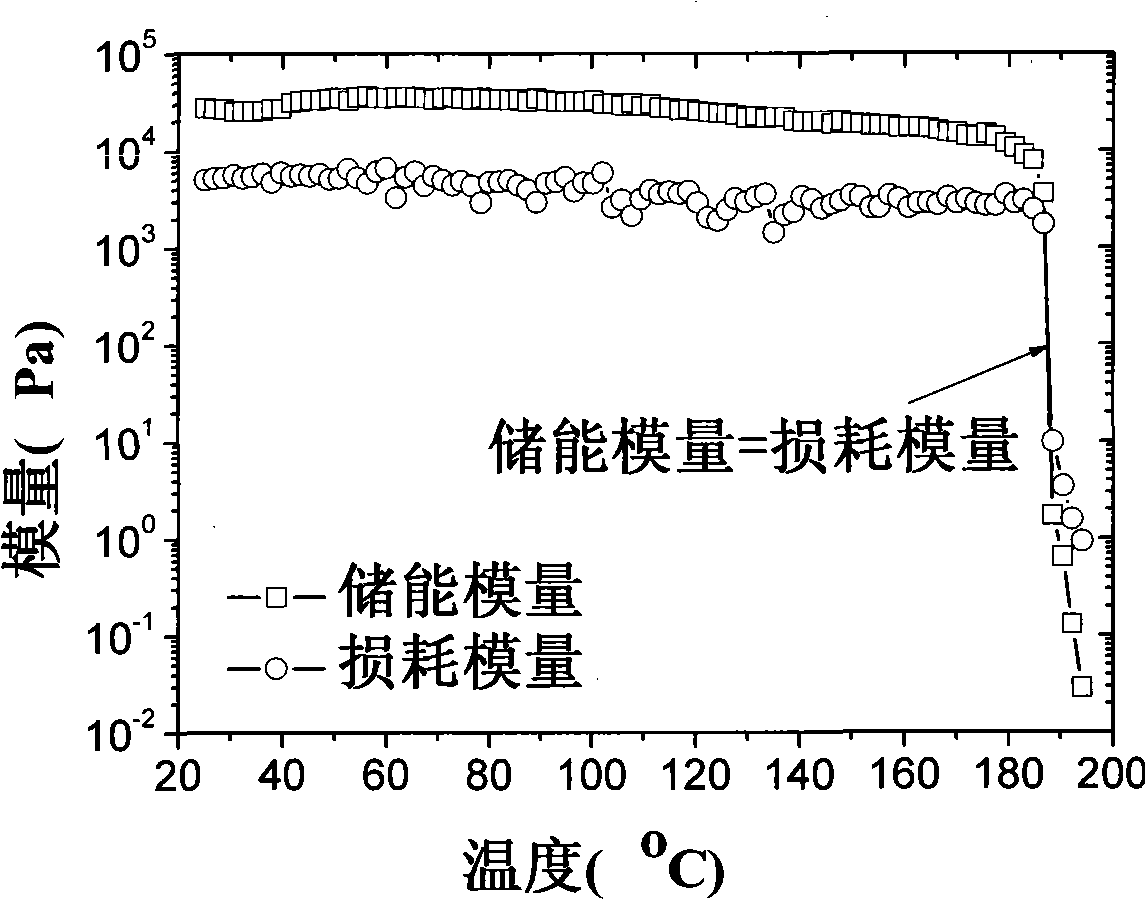

[0036] (2) Apply a sine wave periodic shear stress to the sample through the rheometer control software, the control frequency is 1Hz, the periodic shear stress gradually increases from 1Pa to 2000Pa, and the storage modulus of the sample is measured at 25°C and the loss modulus change curves...

Embodiment 2

[0040] The grease sample used is "3# general lithium base grease" produced by Tianjin Shixun Industry and Trade Co., Ltd., provided by Tianjin Chengke Transmission Electromechanical Technology Co., Ltd. It was tested by the method GB / T4929 of the grease dropping point measurement method in the product standard GB7324-94, and the result was 116°C.

[0041] (1) Using a StressTech rotational rheometer, select a parallel plate accessory with a diameter of 20mm, add a semi-solid grease sample to the lower plate of the selected parallel plate at 25°C, and press down the parallel plate, Control the distance between the upper and lower plates to 1mm, remove excess samples around the upper and lower plates, and keep the samples just filled between the upper and lower plates;

[0042] (2) Apply a sine wave periodic shear stress to the sample through the rheometer control software, the control frequency is 1Hz, the periodic shear stress gradually increases from 1Pa to 1500Pa, and the sto...

Embodiment 3

[0046] The grease sample used is "3# general lithium base grease" produced by Tianjin Shixun Industry and Trade Co., Ltd., provided by Tianjin Chengke Transmission Electromechanical Technology Co., Ltd. It was tested by the method GB / T4929 of the grease dropping point measurement method in the product standard GB7324-94, and the result was 116°C.

[0047] (1) Using a StressTech rotational rheometer, select a parallel plate accessory with a diameter of 20mm, add a semi-solid grease sample to the lower plate of the selected parallel plate at 25°C, and press down the parallel plate, Control the distance between the upper and lower plates to 1mm, remove excess samples around the upper and lower plates, and keep the samples just filled between the upper and lower plates;

[0048] (2) Apply a sine wave periodic shear strain to the sample through the rheometer control software, the control frequency is 1Hz, the periodic shear strain is gradually increased from 0.0001 to 3, and the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com