Permanent magnetic brushless speed-changing motor for electric vehicle and method thereof

A permanent magnet brushless, variable-speed motor technology, applied in electric components, electrical components, electromechanical devices, etc., can solve problems such as unsatisfactory magnetic field weakening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

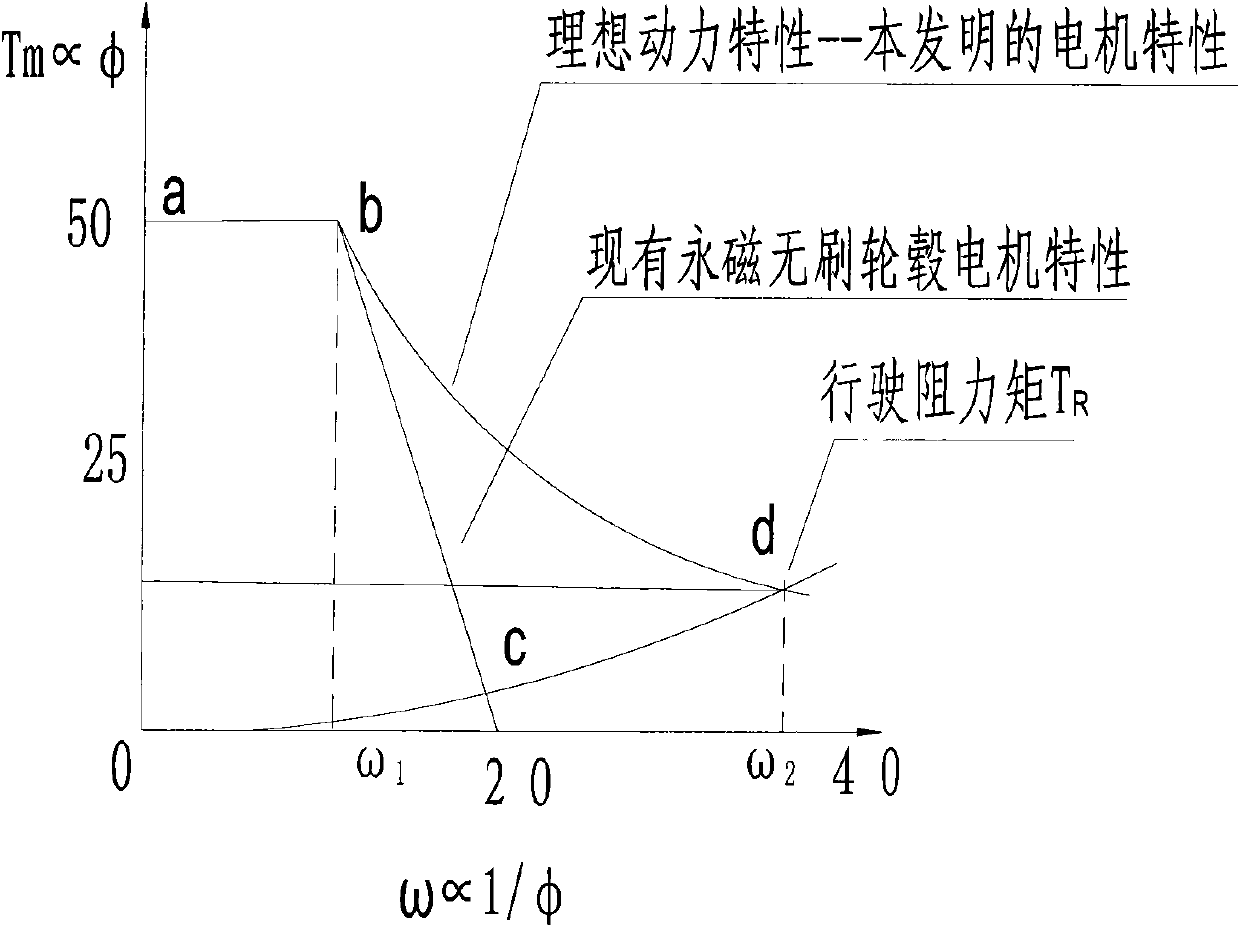

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

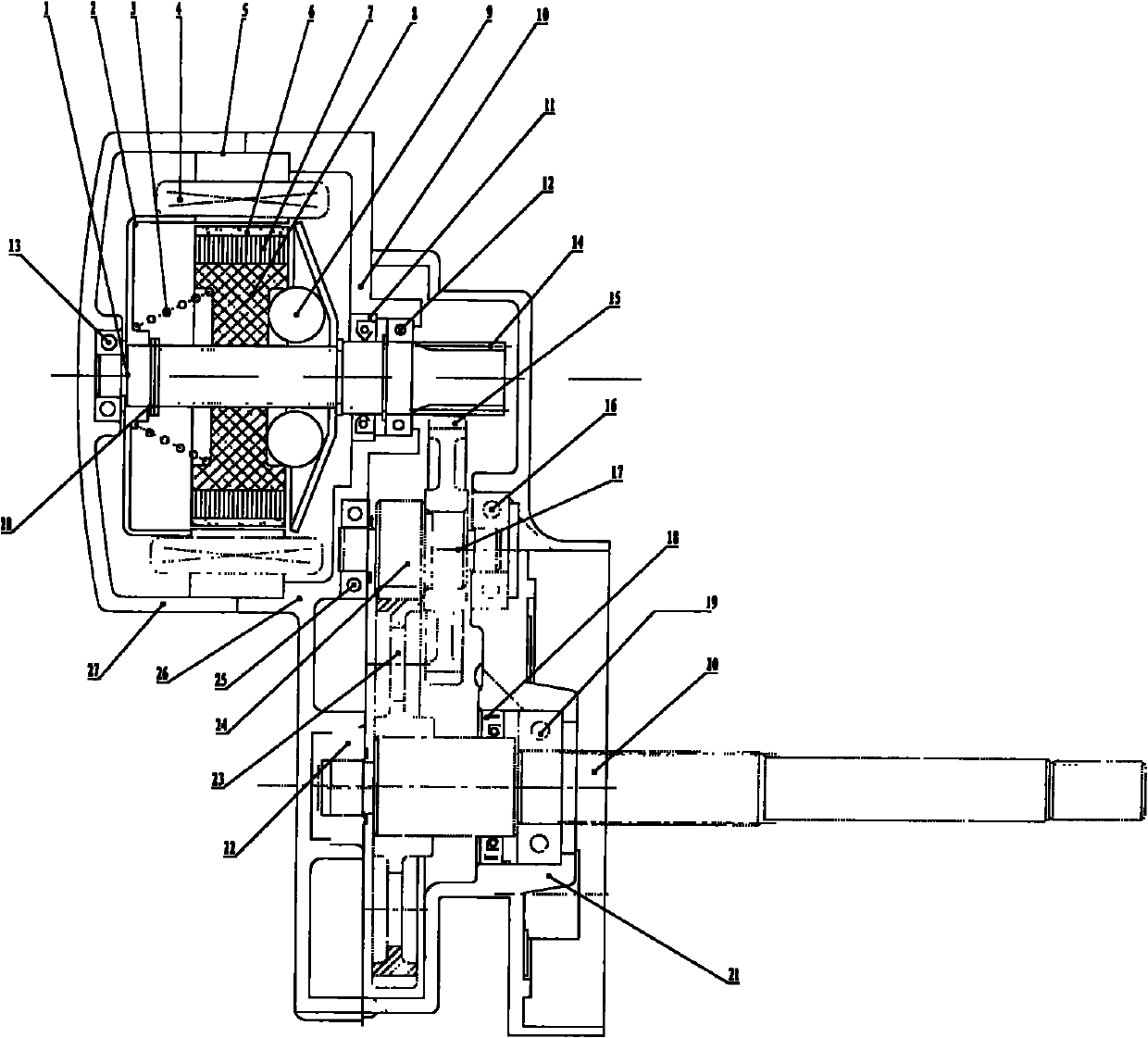

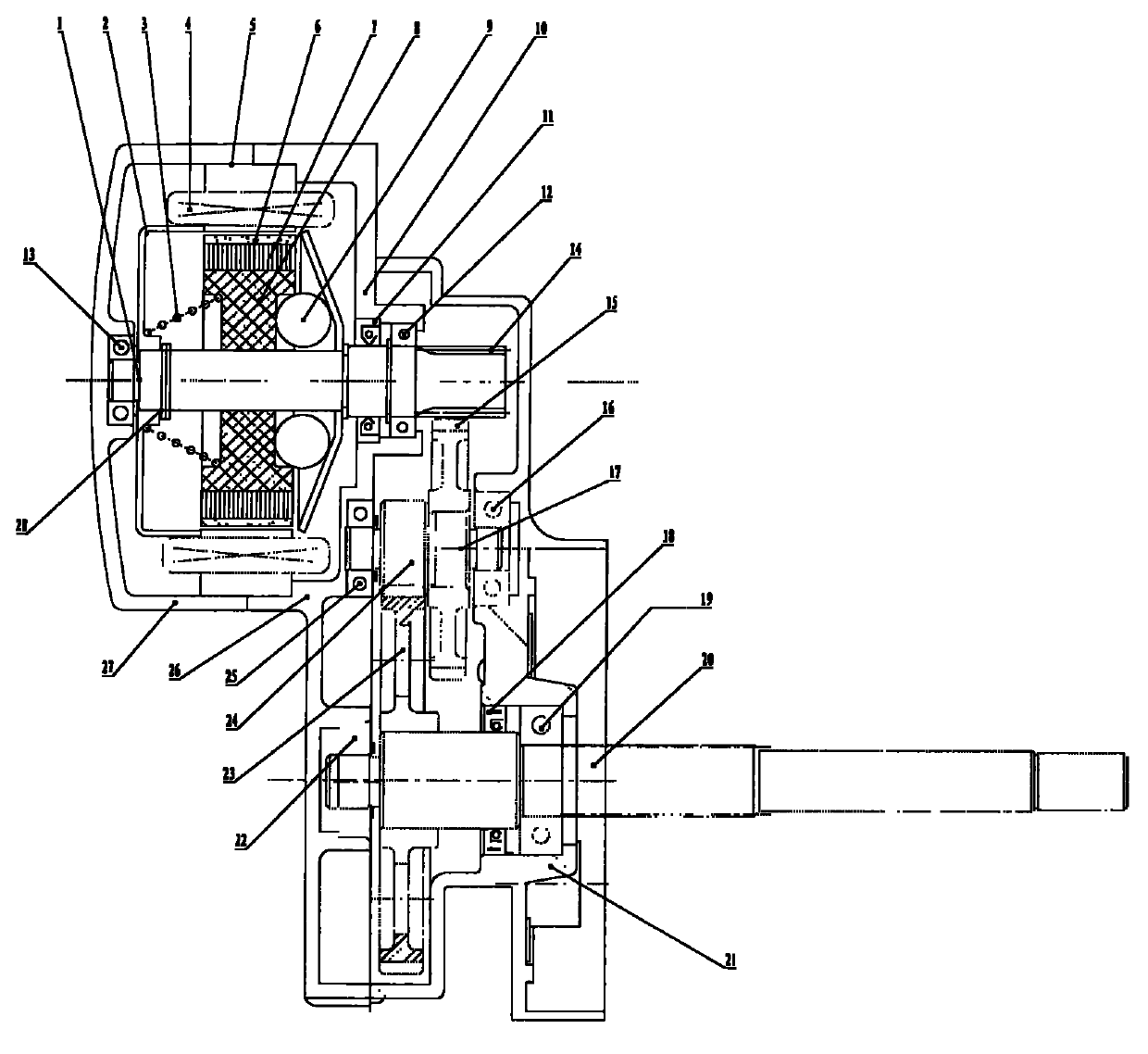

[0019] The present invention is described further in conjunction with accompanying drawing, and the manufacturing technology of this device is very clear to those skilled in the art.

[0020] see figure 1 , The stator of the motor is composed of a winding 4 and a stator core 5, and the stator core is connected to the casing with interference. The casing includes a left box body 26 and a motor cover 27 . The motor shaft 1 is connected to the casing through the bearings 12 and 13, and the motor rotor bracket 8, the magnetic flux shunt 2, and the thrust plate 10 are connected to the shaft; the motor rotor is composed of a permanent magnet 6, a rotor core 7, and a rotor bracket 8; the rotor bracket It is connected with the motor shaft by a spline, which can drive the shaft to rotate and slide axially; the shaft at the left end of the rotor is provided with a magnetic flux shunt 2 with a spring 3 in between; the right end of the rotor is a centrifugal adjustment mechanism, includi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com