Turbomolecular pump

A technology of turbomolecular pumps and rotors, applied in pumps, pump components, axial flow pumps, etc., can solve problems such as reducing the life of rolling bearings, and achieve the effects of reducing heat generation and stress reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

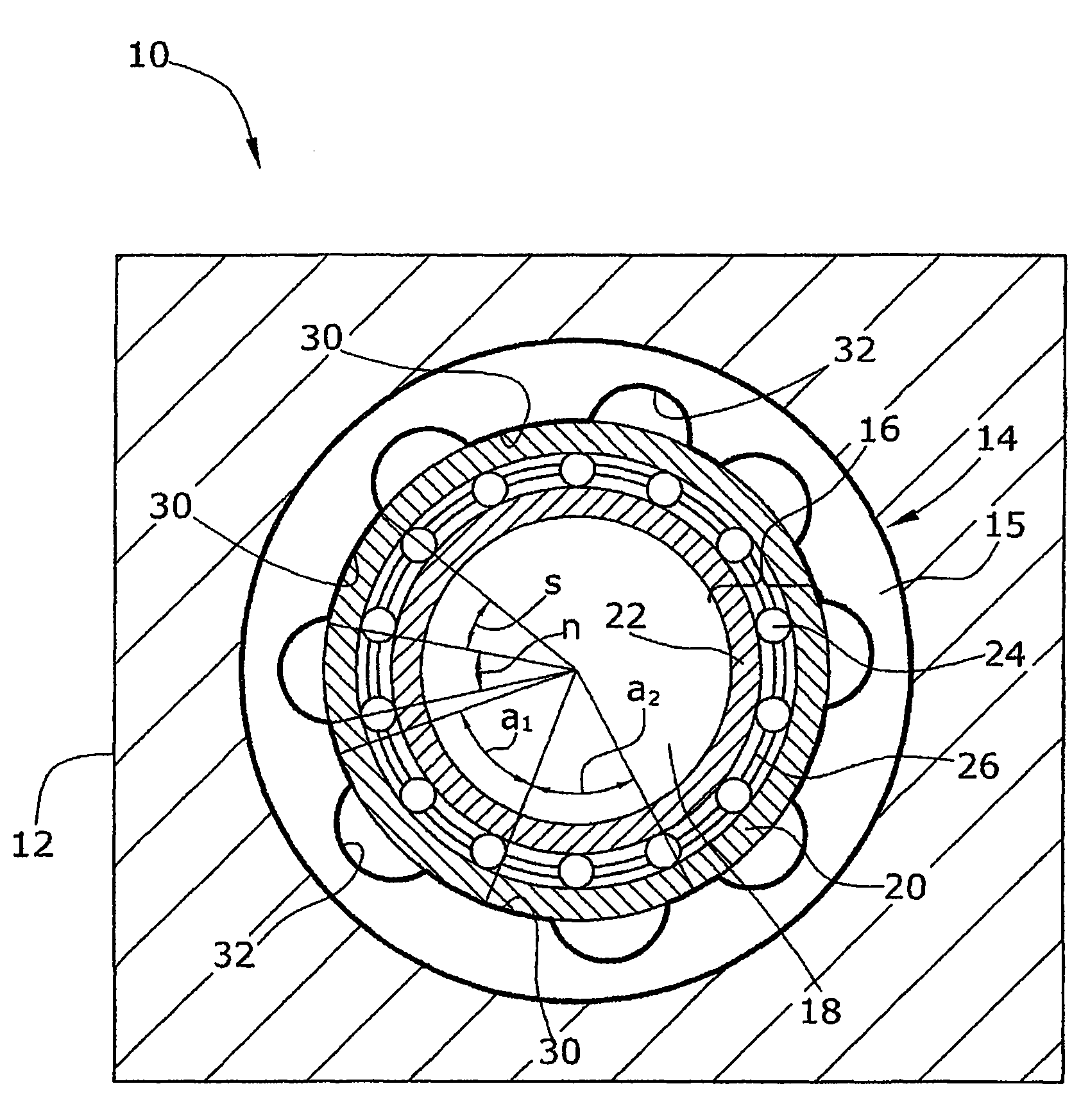

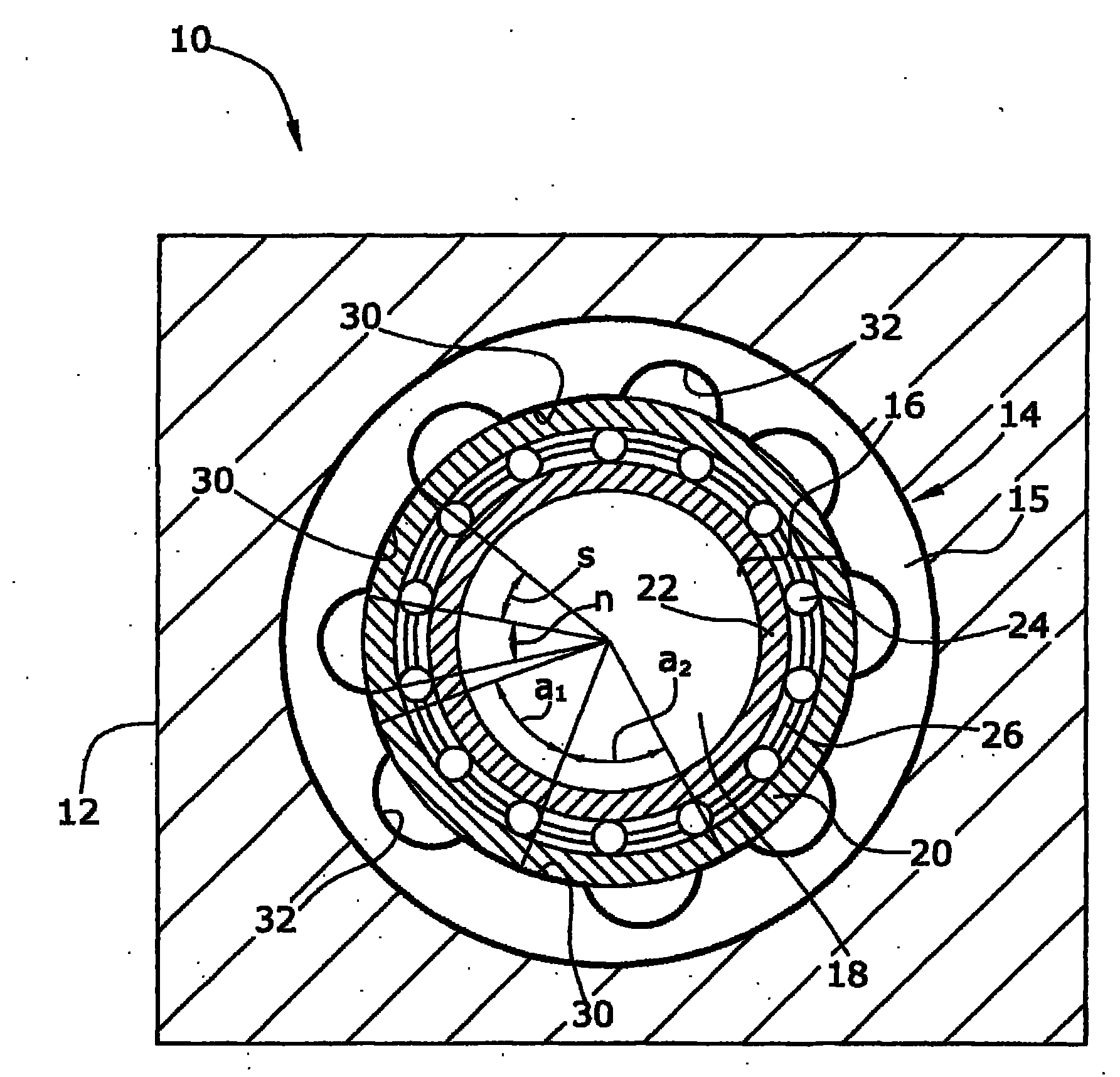

[0016] The figure shows a turbomolecular pump 10 operating at a rated rotational speed well above 10,000 U / min.

[0017] The turbomolecular pump 10 has a housing 12 , on which a rolling bearing 16 is mounted by means of a vibrating ring 14 , and the rolling bearing 16 carries a rotor 18 . The rolling bearing 16 has an outer non-rotating bearing shell 20 , an inner rotating bearing shell 22 , rolling elements 24 and a rolling element cage 26 .

[0018] The vibrating ring 14 is formed integrally from an elastomer and has an anisotropic shape on its circumference. The vibrating ring 14 consists of a plastic body 15 which is formed continuously closed on the housing side in the circumferential direction. The vibrating ring 14 has eight support points 30 distributed irregularly over its circumference, which are formed in the form of radially inner support islands. The fulcrums 30 or support islands 30 are separated from one another by axial grooves 32 which are circular in cross ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com