Process for purifying coarse arsenic

A process, arsenic fume technology, applied in the field of non-metal oxide leaching, can solve the problems of unsafe, no direct use value, environmental pollution and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

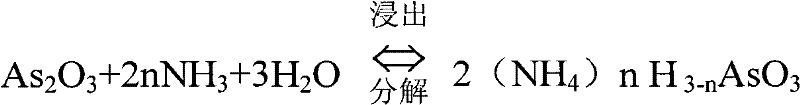

Method used

Image

Examples

Embodiment 1

[0022] 1. Take 100g of high-arsenic fume and put it in a 500mL sealed reaction kettle, add 200mL of ammonia solution with a concentration of 5.0mol / L at a liquid-solid ratio of 2.0:1, and react for 3 hours at a temperature of 50°C.

[0023] 2. Elevate the temperature to evaporate excess ammonia, and the evaporated ammonia is absorbed by the ammonia absorption tower, and the ammonia solution is absorbed to replenish ammonia and then returned to the crude arsenic leaching.

[0024] 3. After distilling ammonia, filter with a vacuum filter, wash with hot water twice the amount of residue, return the filter residue to the raw material for arsenic removal, and remove impurities from the filtrate.

[0025] 4. The material liquid is heated, evaporated and crystallized, and then dried in an oven to remove the adsorbed water.

[0026] 5. The dried crystals are placed in a strip crucible and decomposed in a tube furnace at 500°C. The decomposed solid dust is collected after the tube furn...

Embodiment 2

[0029] 1. Take 1000g of high-arsenic fume and put it in a 5000mL sealed reaction kettle, add 1000mL of ammonia solution with a concentration of 6.0mol / L at a liquid-solid ratio of 1:1, and react at a temperature of 65°C for 5 hours.

[0030] 2. Elevate the temperature to evaporate excess ammonia, and the evaporated ammonia is absorbed by the ammonia absorption tower, and the ammonia solution is absorbed to replenish ammonia and then returned to the crude arsenic leaching.

[0031] 3. After distilling ammonia, filter with a vacuum filter, wash with hot water 1.5 times the amount of residue, return the filter residue to the raw material for arsenic removal, and remove impurities from the filtrate.

[0032] 4. The material liquid is heated, evaporated and crystallized, and then dried in an oven to remove the adsorbed water.

[0033] 5. The dried crystals are placed in a strip crucible and decomposed in a tube furnace at 200°C. The decomposed solid dust is collected after the tube...

Embodiment 3

[0036] 1. Take 1000g of high-arsenic fume and put it in a 10000mL sealed reaction kettle, add 5000mL of ammonia solution with a concentration of 2.0 at a liquid-solid ratio of 5.0:1, and react for 6 hours at a temperature of 30°C.

[0037] 2. Elevate the temperature to evaporate excess ammonia, and the evaporated ammonia is absorbed by the ammonia absorption tower, and the ammonia solution is absorbed to replenish ammonia and then returned to the crude arsenic leaching.

[0038] 3. After distilling ammonia, filter with a vacuum filter, wash with hot water twice the amount of residue, return the filter residue to the raw material for arsenic removal, and remove impurities from the filtrate.

[0039] 4. The material liquid is heated, evaporated and crystallized, and then dried in an oven to remove the adsorbed water.

[0040] 5. The dried crystals are heated to 600°C in the decomposition furnace and decomposed. The decomposed solid dust is collected after cooling in the tube fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com