Internal combustion engine with dry sump lubrication and method for operating the same

A technology of internal combustion engine and dry oil sump, which is applied in the direction of engine lubrication, engine components, machines/engines, etc. It can solve problems such as adverse effects, and achieve the effect of tight packaging, elimination of oil pollution and rapid oil aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] Detailed description of the preferred embodiment

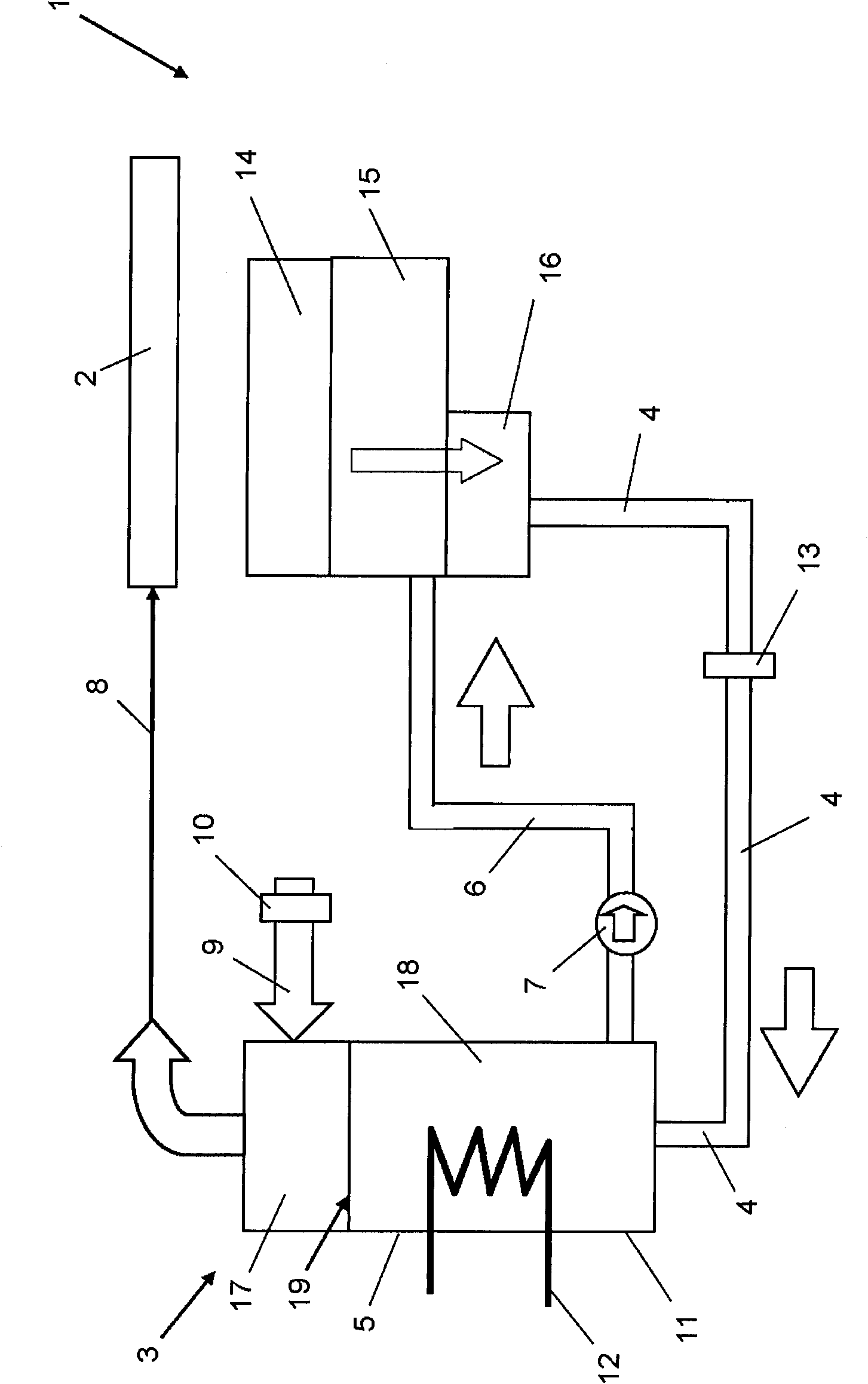

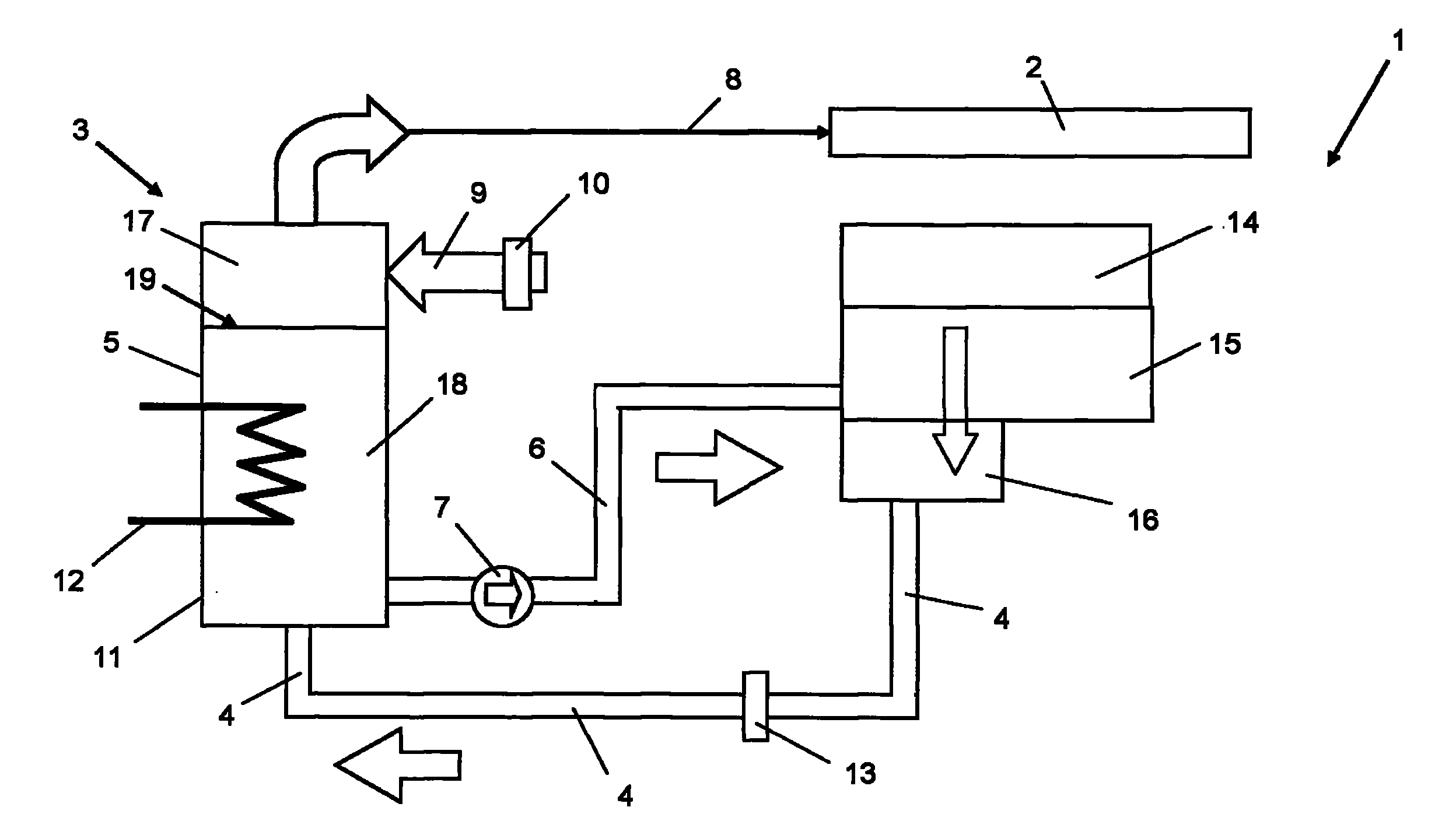

[0080]The internal combustion engine 1 is equipped with an intake area 2 for supplying fresh air and comprises a cylinder head 14, a cylinder block 15 and a collection point 16 which is arranged below the cylinder block 15 and where oil 18 is collected to form oil Bottom case 16. In this case, the return of oil from the cylinder head 14 and cylinder block 15 takes place in a gravity-driven manner, as clearly indicated by the arrows.

[0081] figure 1 The illustrated internal combustion engine 1 has a dry sump lubrication 3 , the oil 18 collected at a collection point 16 is led via a discharge line 4 into a container 5 for storing the oil 18 . In order to prevent undesired backflow, a non-return valve 13 is arranged in the discharge line 4 . The oil 18 introduced into the container 5 forms an oil level 19 . Above the oil level 19 there is a gas 17 which fills the remaining space of the container 5 .

[0082] Below t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com