Production method for liquid-core optical fibre and quartz optical fibre coupling device

A technology of quartz optical fiber and liquid core optical fiber, which is applied in the optical field, can solve problems such as poor firmness, rough packaging, and large loss, and achieve the effects of enhanced tightness, reduced coupling loss, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] Specific Embodiments 1. The manufacturing method of the liquid core optical fiber and quartz optical fiber coupling device described in this embodiment, the method is realized by the following steps:

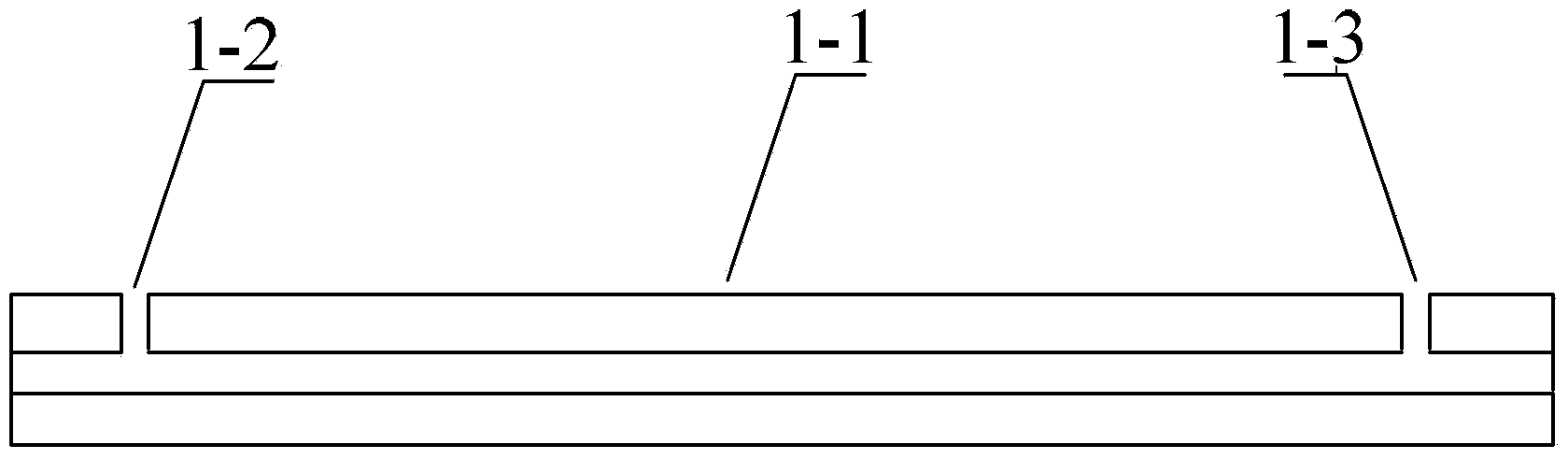

[0023] Step 1. Using a femtosecond micromachining device to make two small holes with a diameter of 2 μm to 5 μm at both ends of a hollow fiber 1-1, namely: the first opening 1-2 and the second opening 1-3, The first opening 1-2 and the second opening 1-3 are 1 cm to 3 cm away from the left end and right end of the hollow fiber 1-1 respectively, and the first opening 1-2 and the second opening are sealed by pressurized gas assisted hydrofluoric acid. Clean the processing debris at 1-3;

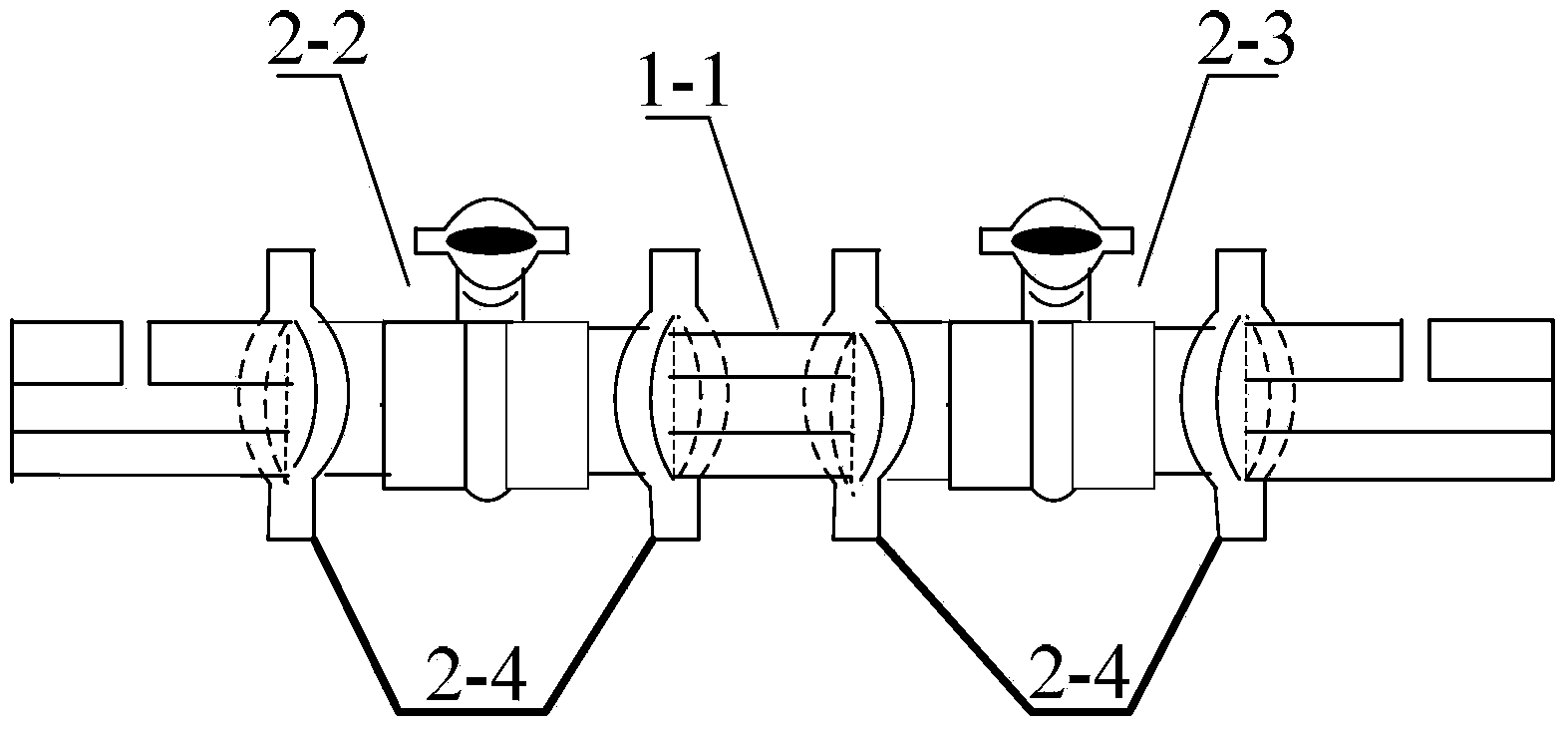

[0024] Step 2, the first three-way 2-2 and the second three-way 2-3 are both sleeved on the hollow fiber, and moved to the first opening 1-2 and the second opening 1-3 on the hollow fiber 1-1 between;

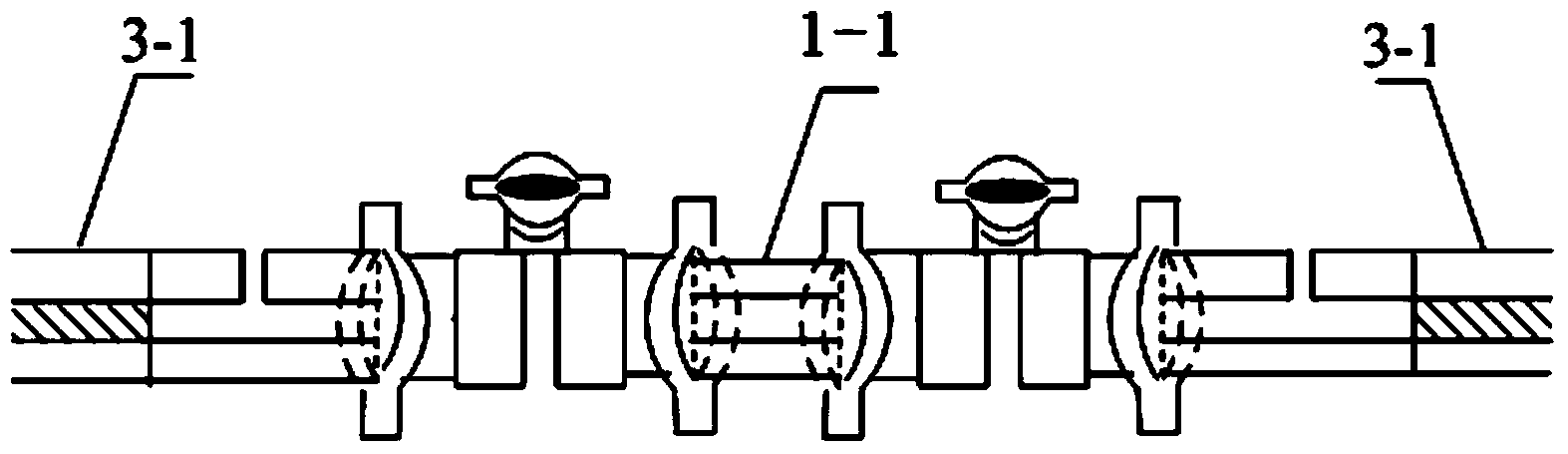

[0025] Step 3: Cut one end of the two quartz optical fibers 3-1 and the end faces of...

specific Embodiment approach 2

[0035] Embodiment 2. The difference between this embodiment and the manufacturing method of the liquid core optical fiber and quartz fiber coupling device described in Embodiment 1 is that the first three-way 2-2 and the second three-way in the second step 2-3 forms a symmetrical structure along the vertical plane that equally divides the hollow-core optical fiber 1-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com