Automatic return valve

A technology of automatic reset and drive shaft, applied in the direction of valve details, multi-way valves, valve devices, etc., can solve the problems of inconvenient user operation, inability to ensure accurate switching, over-rotation or non-rotation, etc., to achieve convenient processing and assembly , the effect of accurate switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

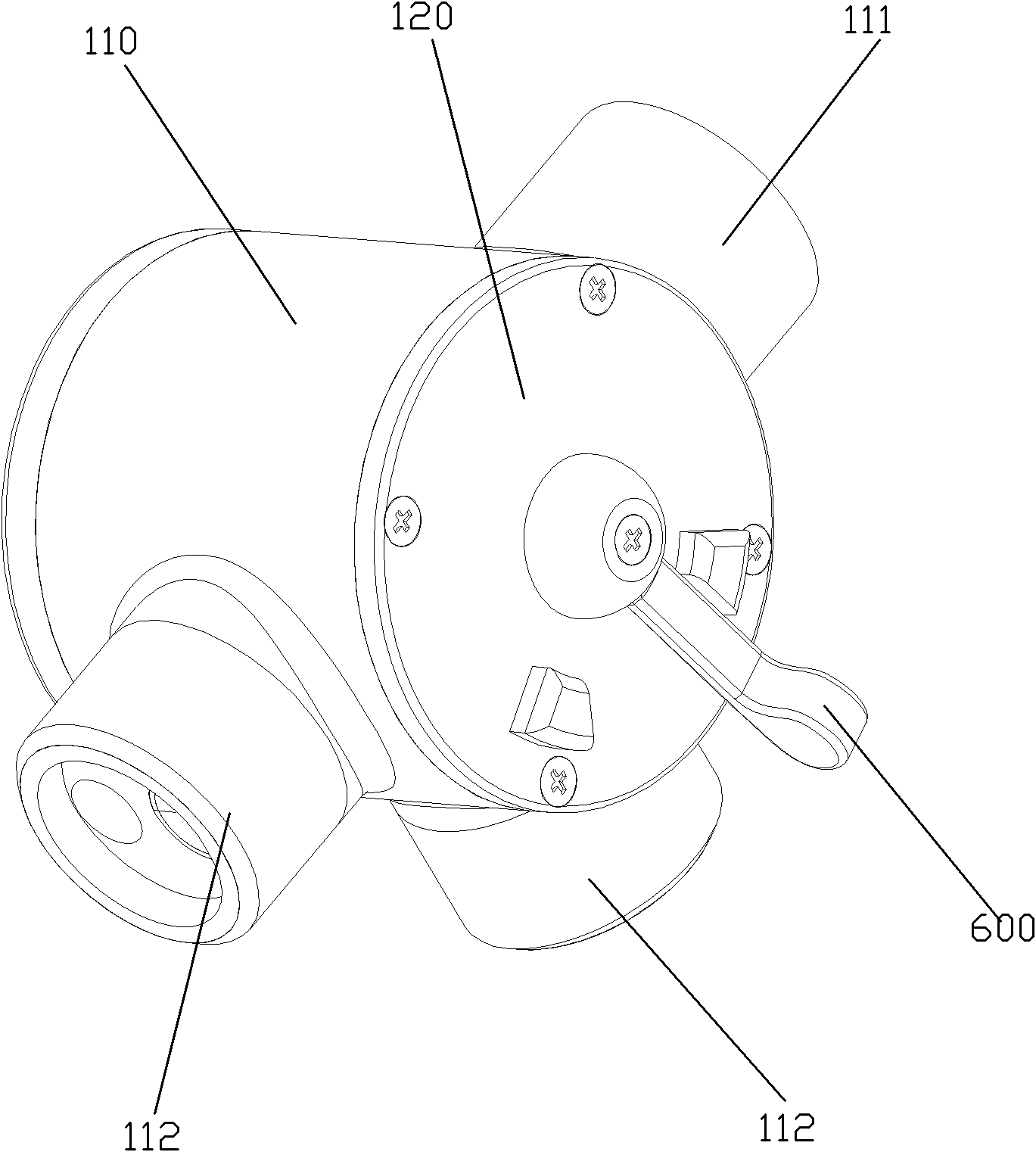

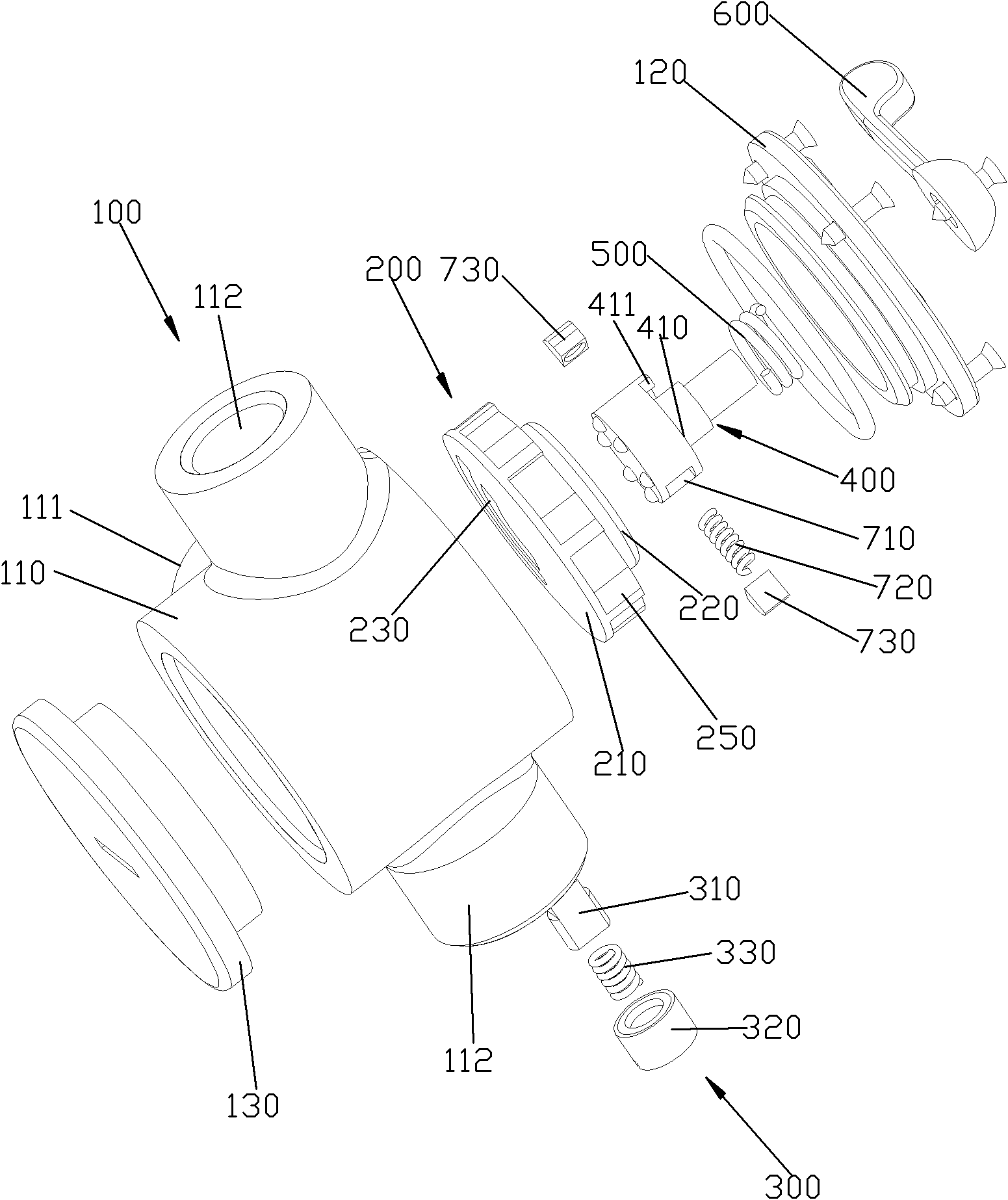

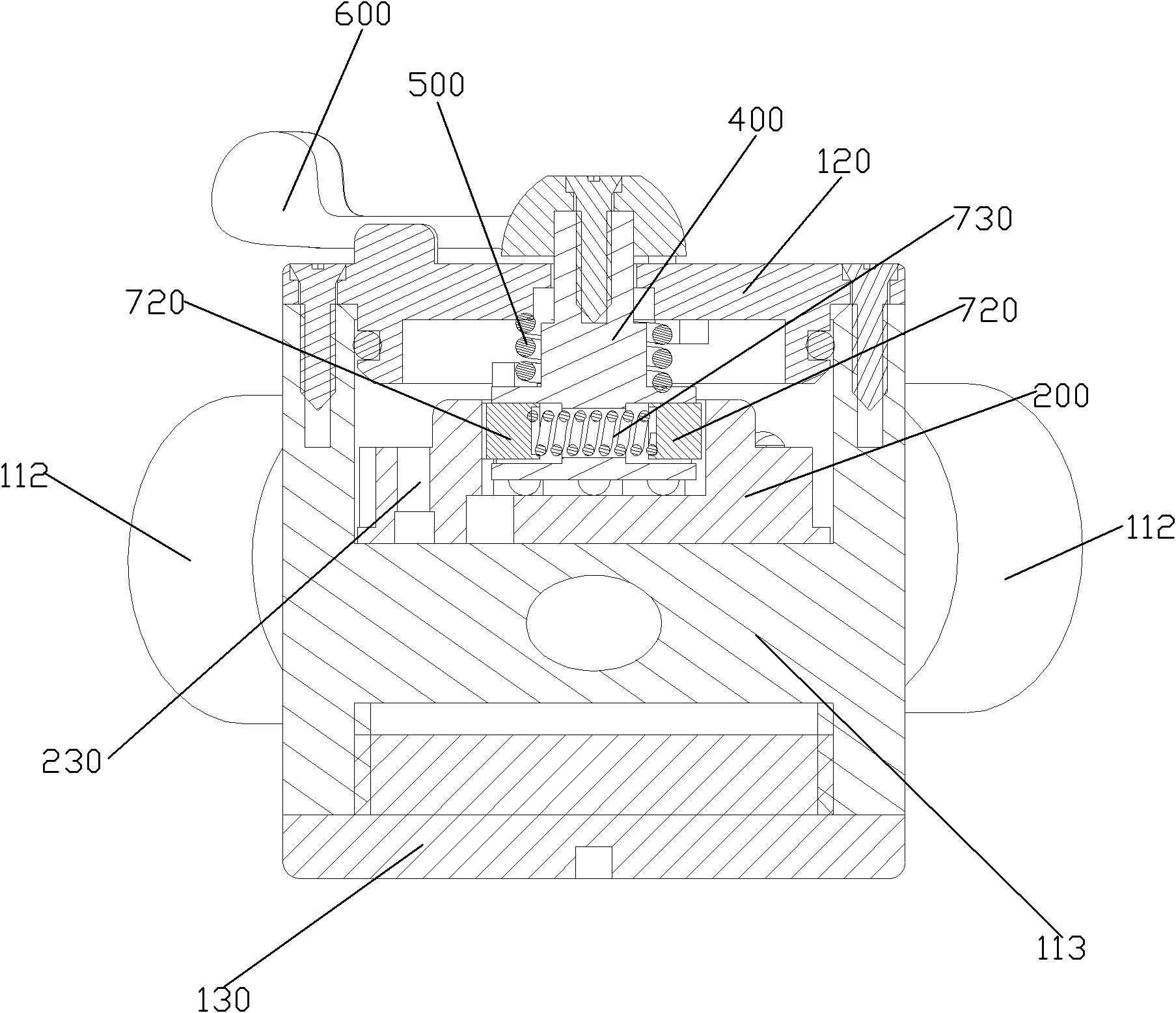

[0045] Please check Figure 1 to Figure 12 , an automatic reset valve, which includes a fixed unit 100, a sub-water body 200, a stop mechanism 300, a transmission shaft 400, a clutch mechanism, a reset elastic body 500 and a rocker 600.

[0046] Please check Figure 1 to Figure 12 ,especially figure 2 , image 3 and Figure 7 , the fixing unit 100 includes a main body 110 , an upper cover 120 and a lower cover 130 .

[0047] The main body 110 is in the form of a set, and is provided with a water inlet 111 and two water outlets 112, the water inlet 111 can be connected to an external water source, and the two water outlets 112 can be respectively connected to the external two water outlet functions; the main body 110 has Inner hole, described inner hole is provided with a dividing plate 113, is provided with the water-distributing hole 114 of group number equal to water outlet 112 above described dividing plate 113, and described water-dividing hole 114 and water outlet 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com