Side-view type LED packaging structure as well as production method and application thereof

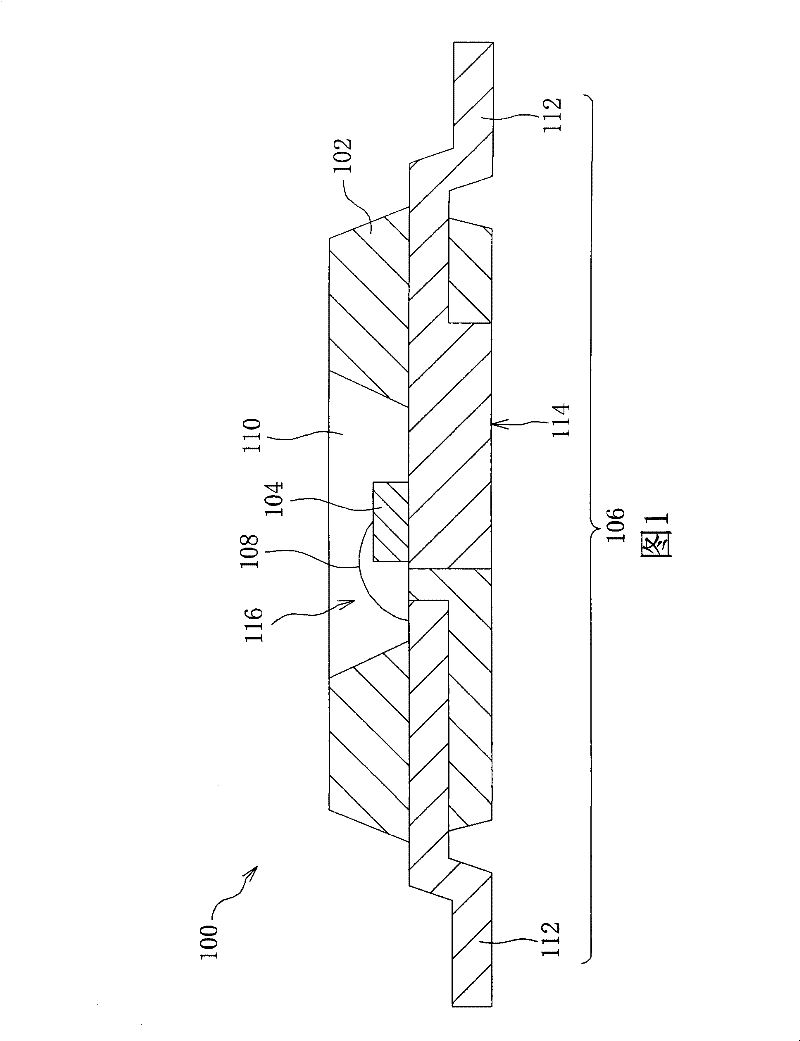

A technology of light-emitting diodes and packaging structures, applied in the directions of optics, light guides, light sources, etc., can solve the problems of uneven thickness, large size, and large difference in expansion coefficient of semiconductor materials of conductive pins 106, and achieve reduced manufacturing difficulty and good heat dissipation Characteristics, Effects of Excellent Thermal Conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

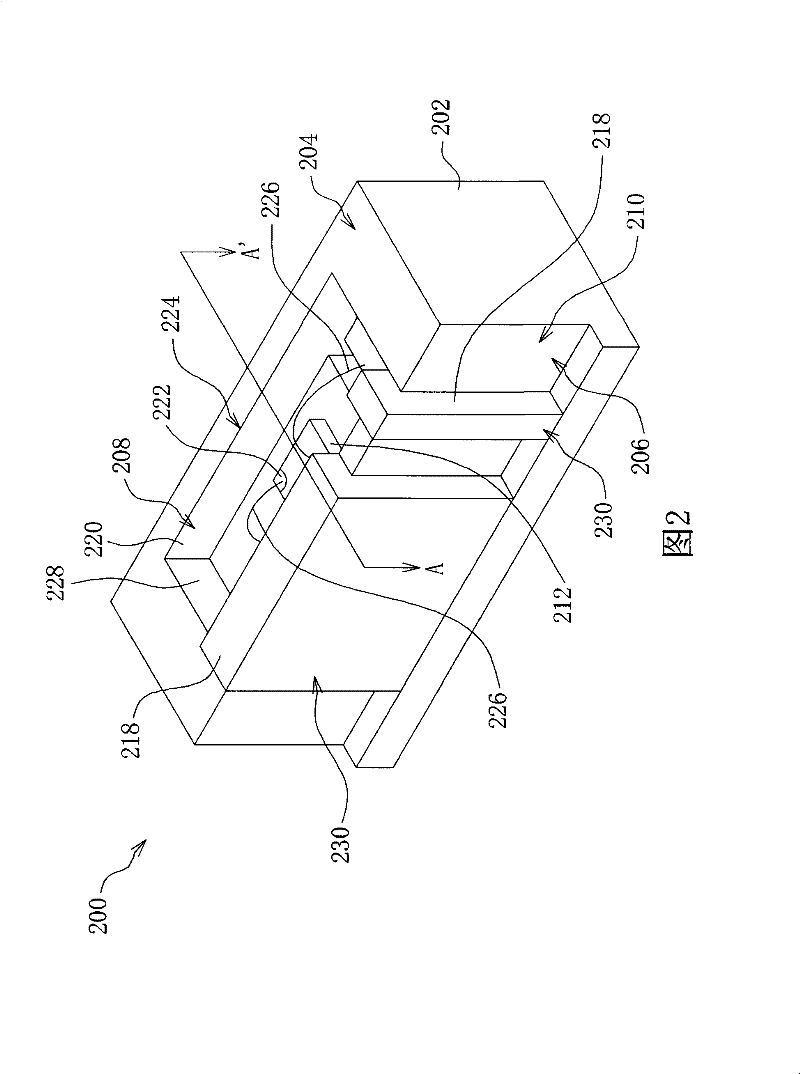

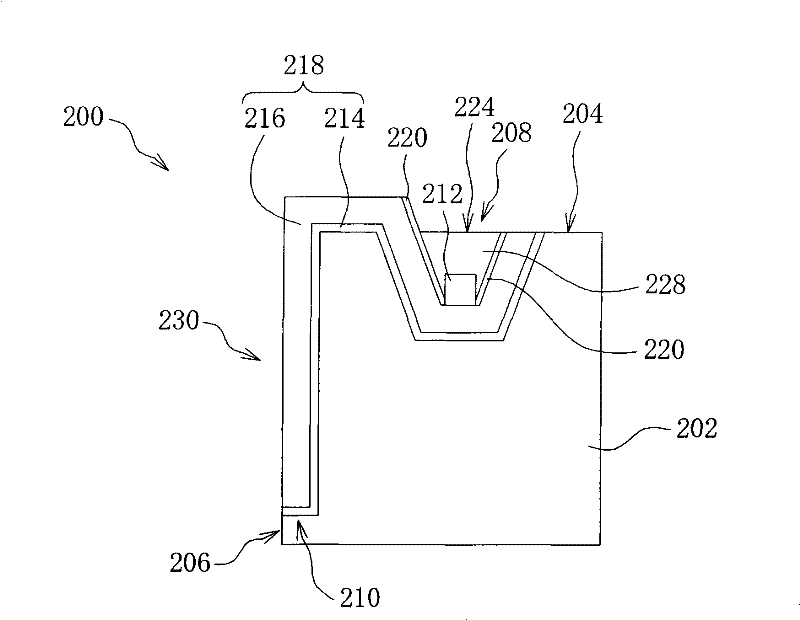

[0060] Please refer to figure 2 and image 3 , which respectively depict a perspective view of a side-view light-emitting diode packaging structure according to a preferred embodiment of the present invention, and along the figure 2 The cross-sectional view of the package structure of the side-view light-emitting diode obtained by the section line AA'. The side-view LED packaging structure 200 mainly includes a silicon base 202 , two conductive pins 218 , one or more LED chips 212 and an encapsulant 228 . In this exemplary embodiment, the silicon base 202 is an integrally formed structure. In one embodiment, the silicon base 202 has adjacent surfaces 204 and 206, wherein the silicon base 202 includes at least a groove 208, and the groove 208 is disposed in the surface 204 of the silicon base 202, wherein the groove 208 defines The light emitting surface 224 of the side-view LED packaging structure 200 is emitted. In the exemplary embodiment, the silicon base 202 further ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com