Single-phase motor-driving device with energy saving module

A motor-driven, energy-saving module technology, applied in electromechanical devices, emergency protection circuit devices, motor generator control, etc., can solve the problems of single-phase motor vibration, noise, large power consumption, and lack of current smoothing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

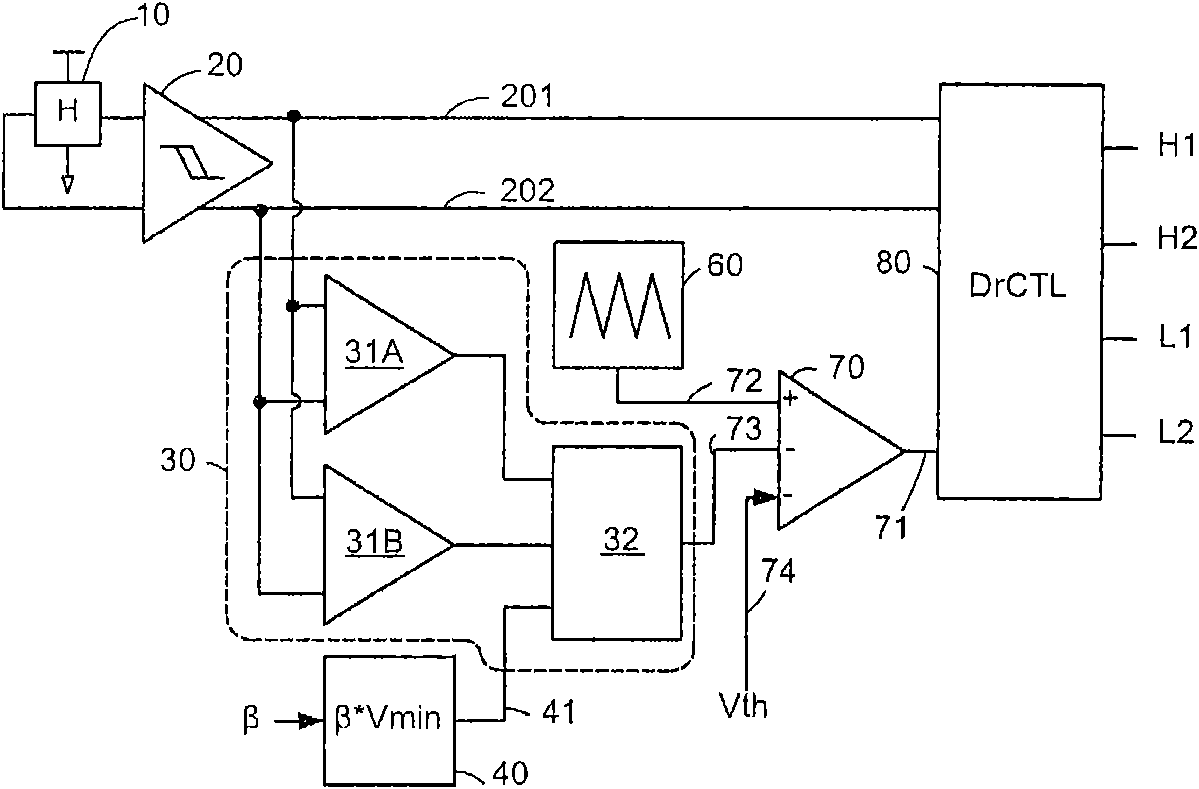

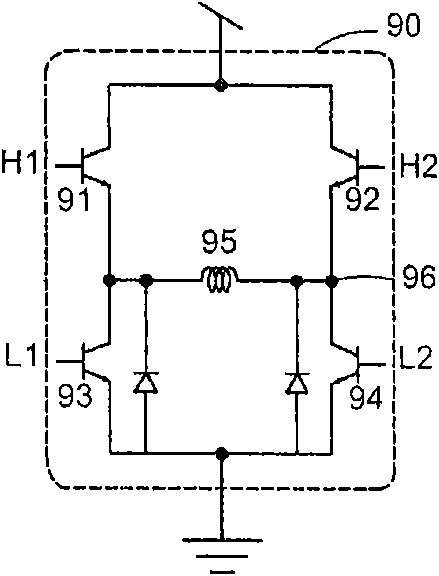

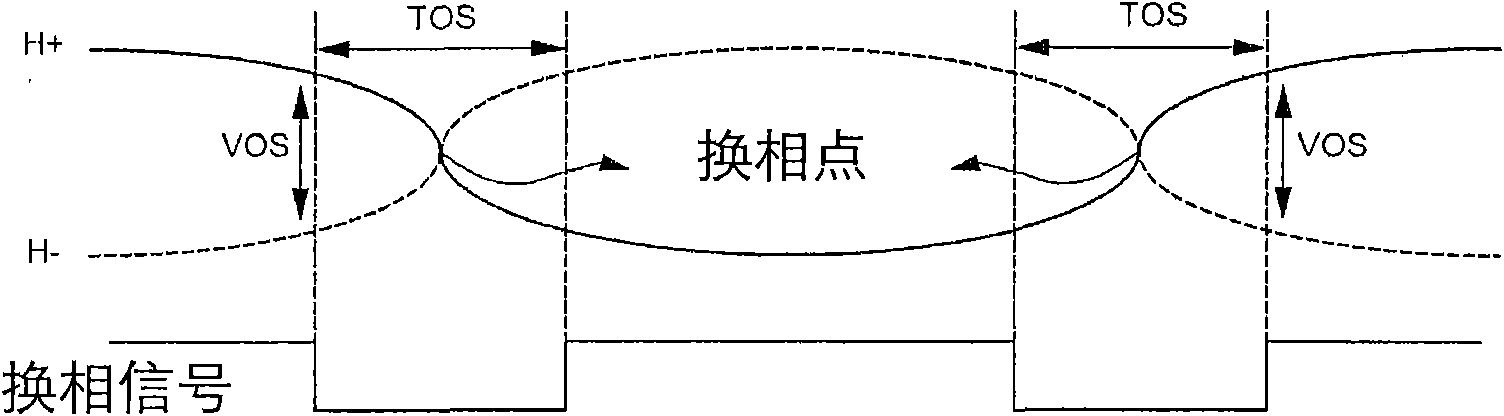

[0059] Since the present invention discloses a single-phase motor drive device configured with an energy-saving control module, especially an energy-saving control module is configured in a single-phase motor drive device, and at the same time, it can be recommutated by the phase change configured in the single-phase motor drive device. A point sampling circuit is used to generate a periodic specific time width, and within the range of this specific time width, at least one control signal is selected for modulation, so that the driving current on the induction coil forms a symmetrical and smooth drive in a specific time width current to make single-phase motor speed more stable and more energy efficient. However, because the present invention is used to drive the single-phase motor driver to generate the control signal of the drive current and Figure 8B and Figure 9B The ones shown are the same, so in the following description, a complete description will not be made; in ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com