Dental inlay graft measuring/machining system

A technology for processing systems and inlays, used in dentistry, dental prosthesis, medical science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

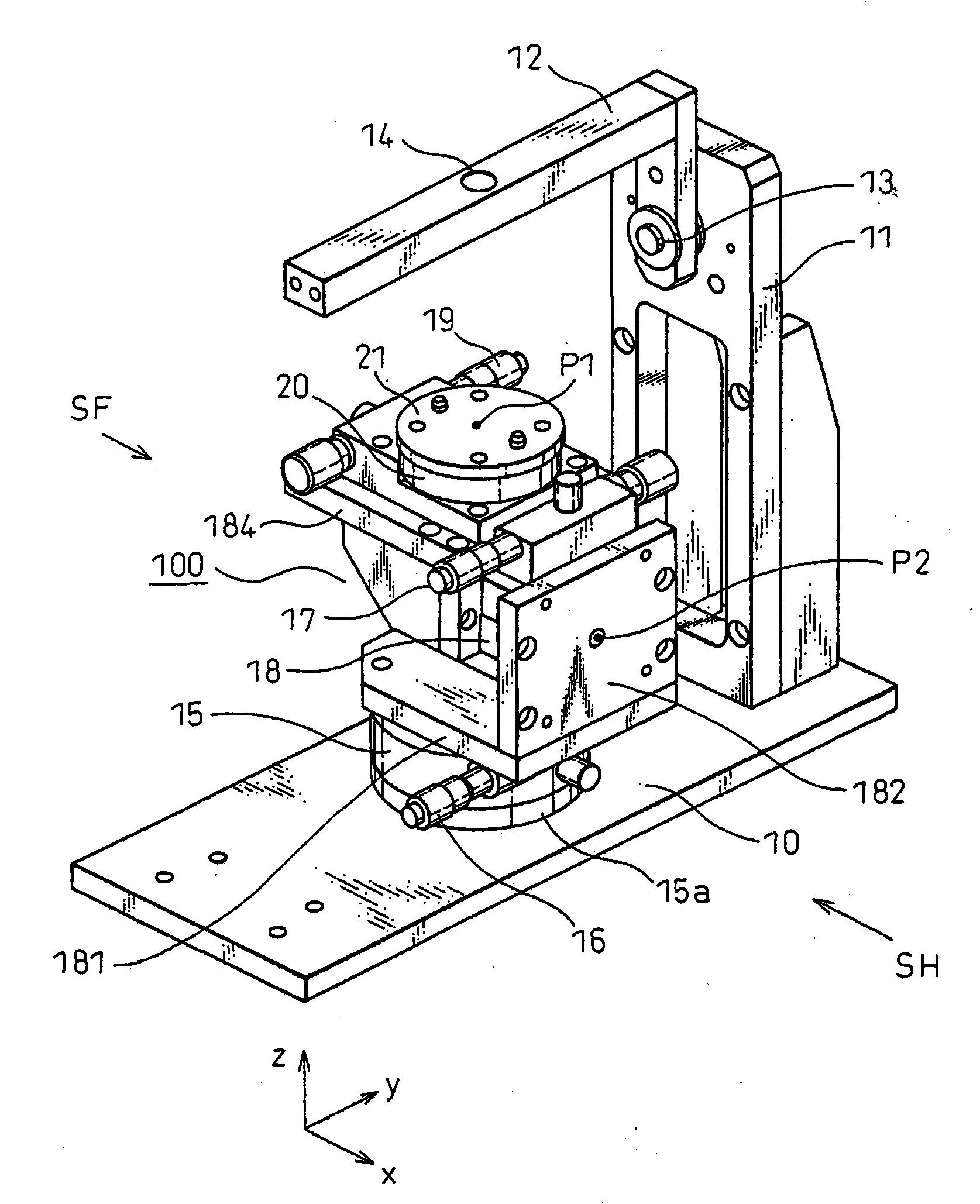

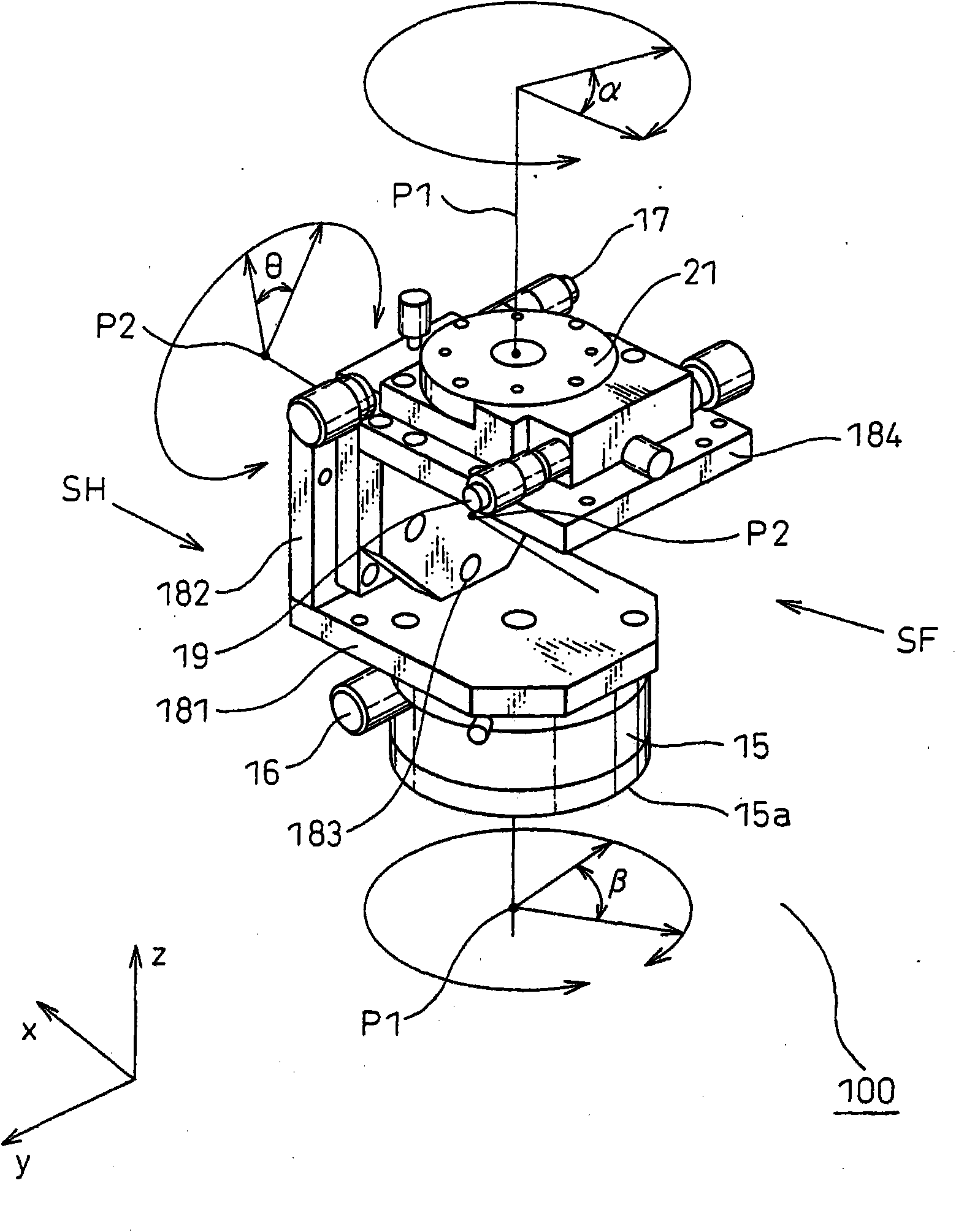

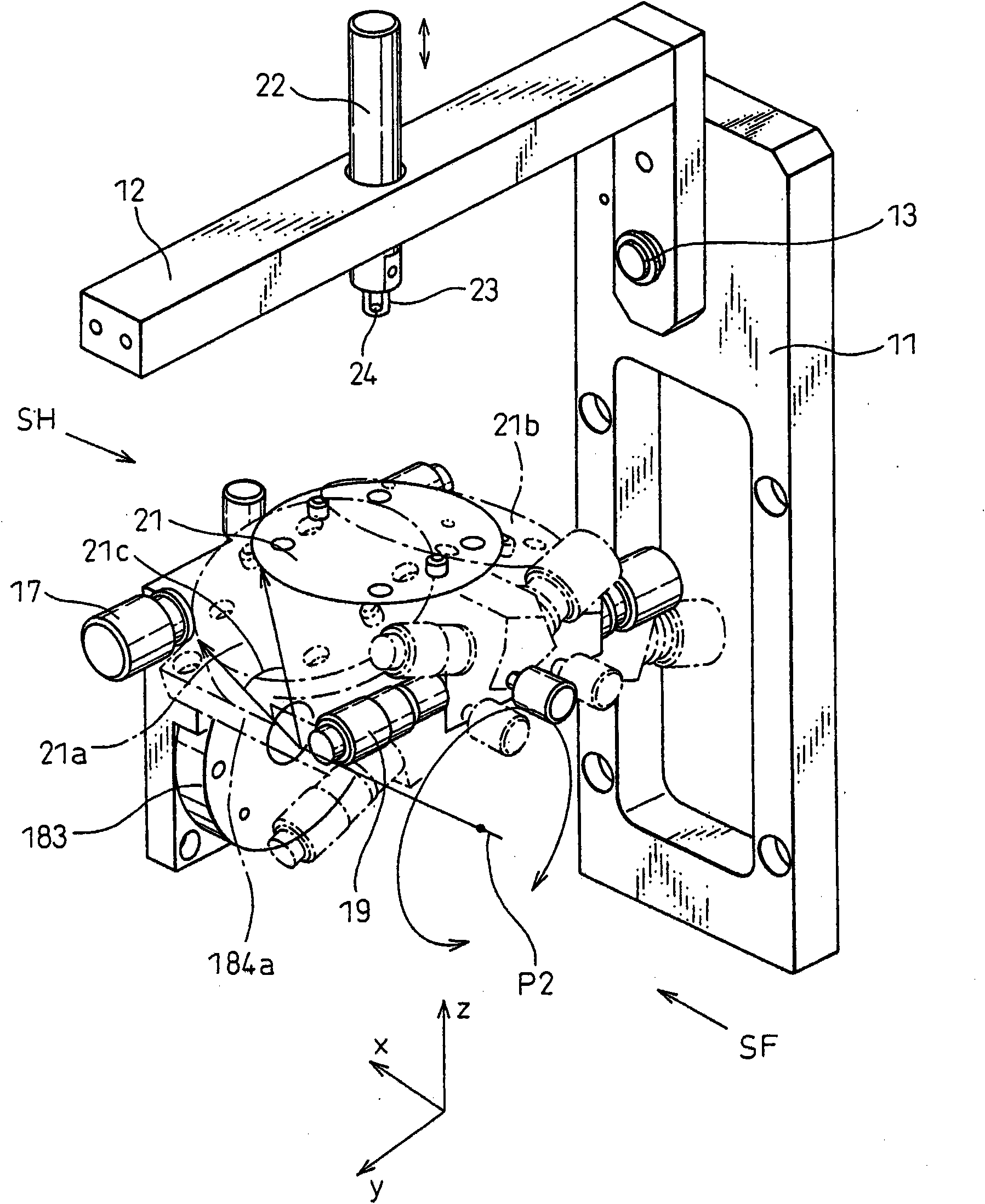

[0147] Next, embodiments of the present invention will be described in detail with reference to the drawings.

[0148] figure 1 and figure 2 It is a figure which shows the state of the dental inlay measuring processing system of this invention seen from the front and back. figure 1 is the state seen from the SH direction, figure 2This is the state seen from the SF direction. The x, y, and z coordinates in the figure are described as being arbitrarily set based on the orientation of the adjustment device 100 . The direction of the arrow is, for example, the positive direction. In each figure, the direction of the adjusting device 100 is indicated by SH and SF. Since the adjusting device 100 is coupled to the substrate 10 by magnetic force, it is in a state where it can slide and move by applying a slight force if it is on the substrate 10 .

[0149] exist figure 1 Among them, the adjusting device 100 is a tool for rotating and moving the implant model placed on the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com