Drilling tool with drill bit

A technology of drilling tools and drill bits, which is applied in the direction of manufacturing tools, drilling/drilling equipment, parts of boring machines/drilling machines, etc. It can solve the problems of known drilling tools such as difficult operation, complicated manufacturing, and material weakening, and achieve simple The effect of interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

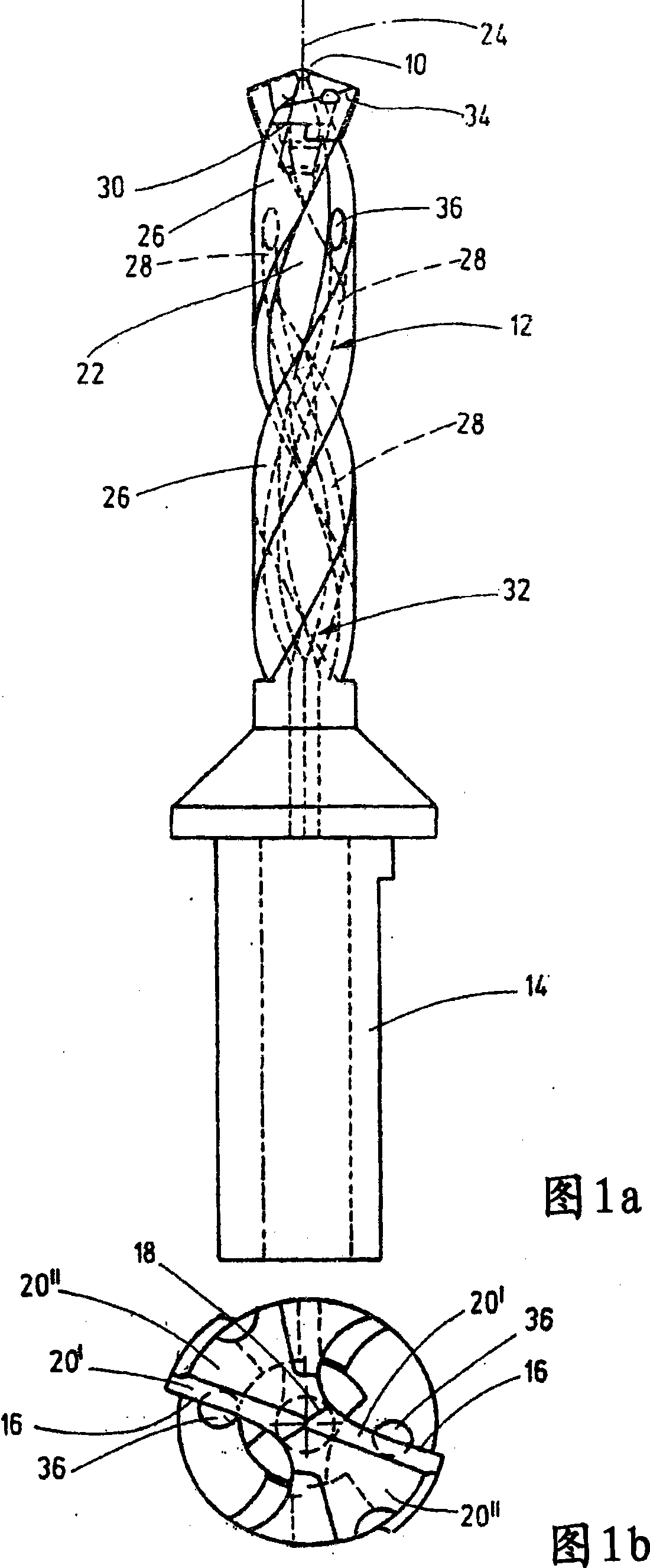

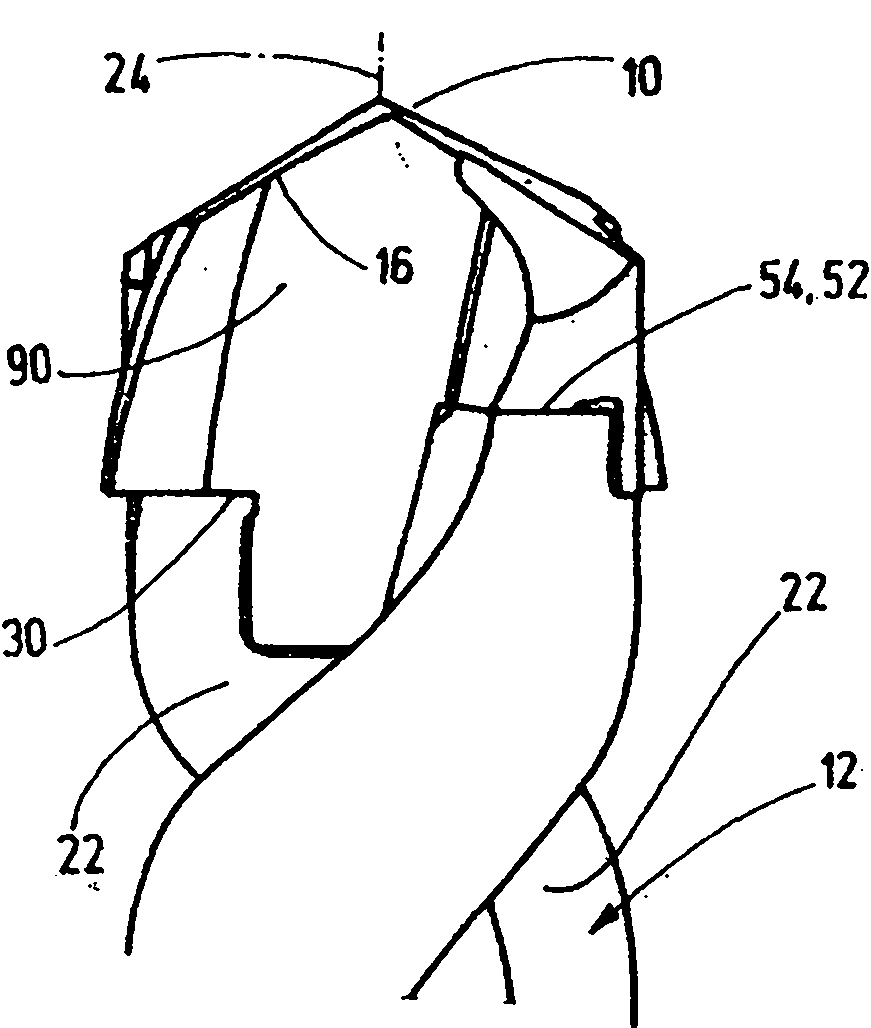

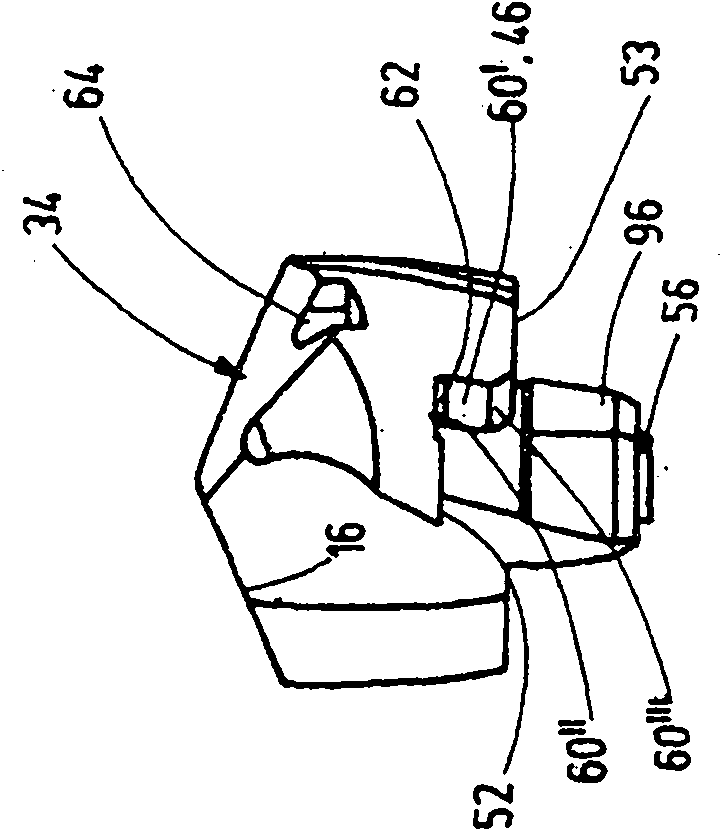

[0025] The drilling tool shown in the figures is divided into two parts at a separation point 30 and comprises a base body 32 with a shank 14 and a drill crown 34 with a drill tip 10 . The drill crown 34 and the base body 32 can be connected to one another in a form-fitting and force-fitting manner at the separation point 30 . The base body 32 is preferably made of tool steel or high-speed steel, while the drill crown 34 is constructed as a shaped part made of a cutting material selected from the group of cemented carbides or ceramics, which is produced and sintered as a sintered powder Injection molded parts or powder extrusion molded parts. In principle, the drill crown 34 can also be produced from tool steel coated with a wear-resistant layer.

[0026] Figure 1a to Figure 1cThe shown drilling tool has a drill tip 10 , a chip evacuation section 12 connected to the drill tip and a drill shank 14 formed behind the chip evacuation section 12 . The drill point 10 comprises t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com