Disc brake, in particlar for a utility vehicle

一种盘式制动器、商用车的技术,应用在制动器类型、制动器的部件、松弛调节器等方向,能够解决费用等问题,达到少费用的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

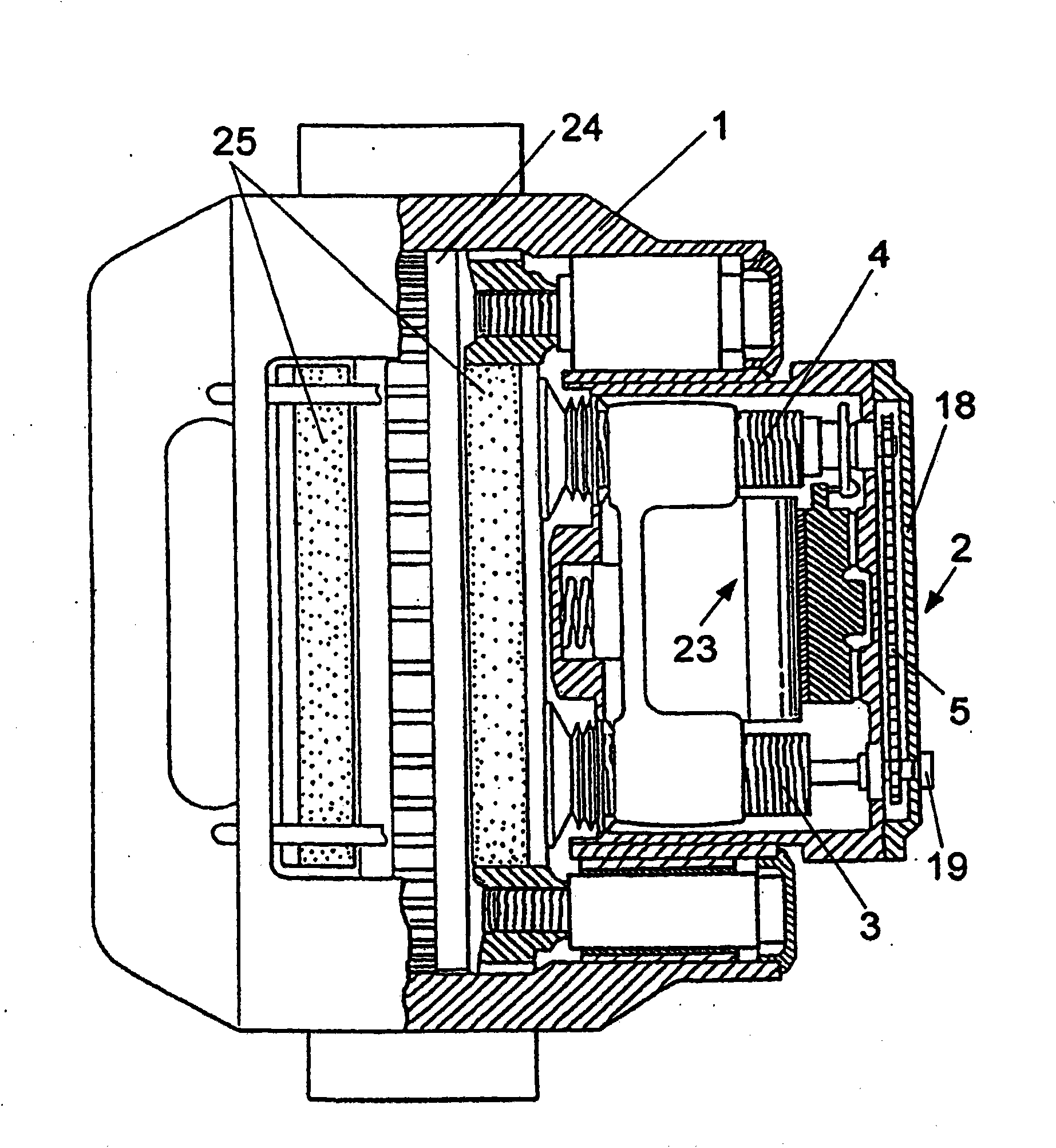

[0024] exist figure 1 A disc brake, in particular for commercial vehicles, is shown in the figure, which comprises a brake caliper 1 which bridges a brake disc 24, each brake disc which is arranged on both sides of the brake disc 24 and contacts the brake disc during braking. Brake lining 25, a clamping device 23 and a readjustment device 2, by which the brake lining 25 on the clamping side can be pressed against the brake disc 24, wherein the two adjusting screws 3, 4 is transmitted to the brake lining 25 by the clamping device 23, and the wear-induced changes in the air gap between the brake lining 25 and the brake disc 24 can basically be compensated by said readjustment device. Variety. In this case, the readjustment device 2 is arranged on an adjusting screw 3 in a rotationally fixed manner.

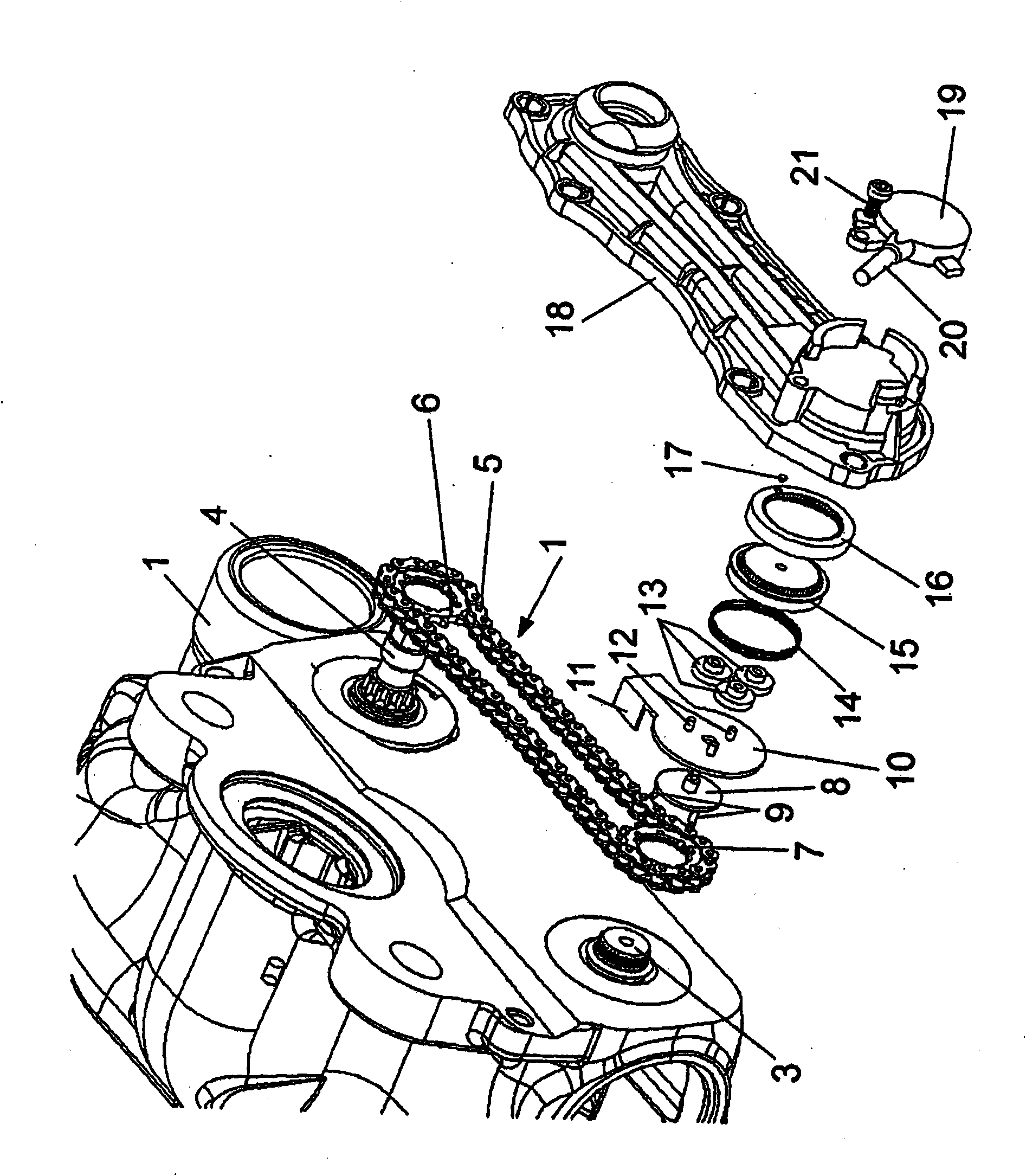

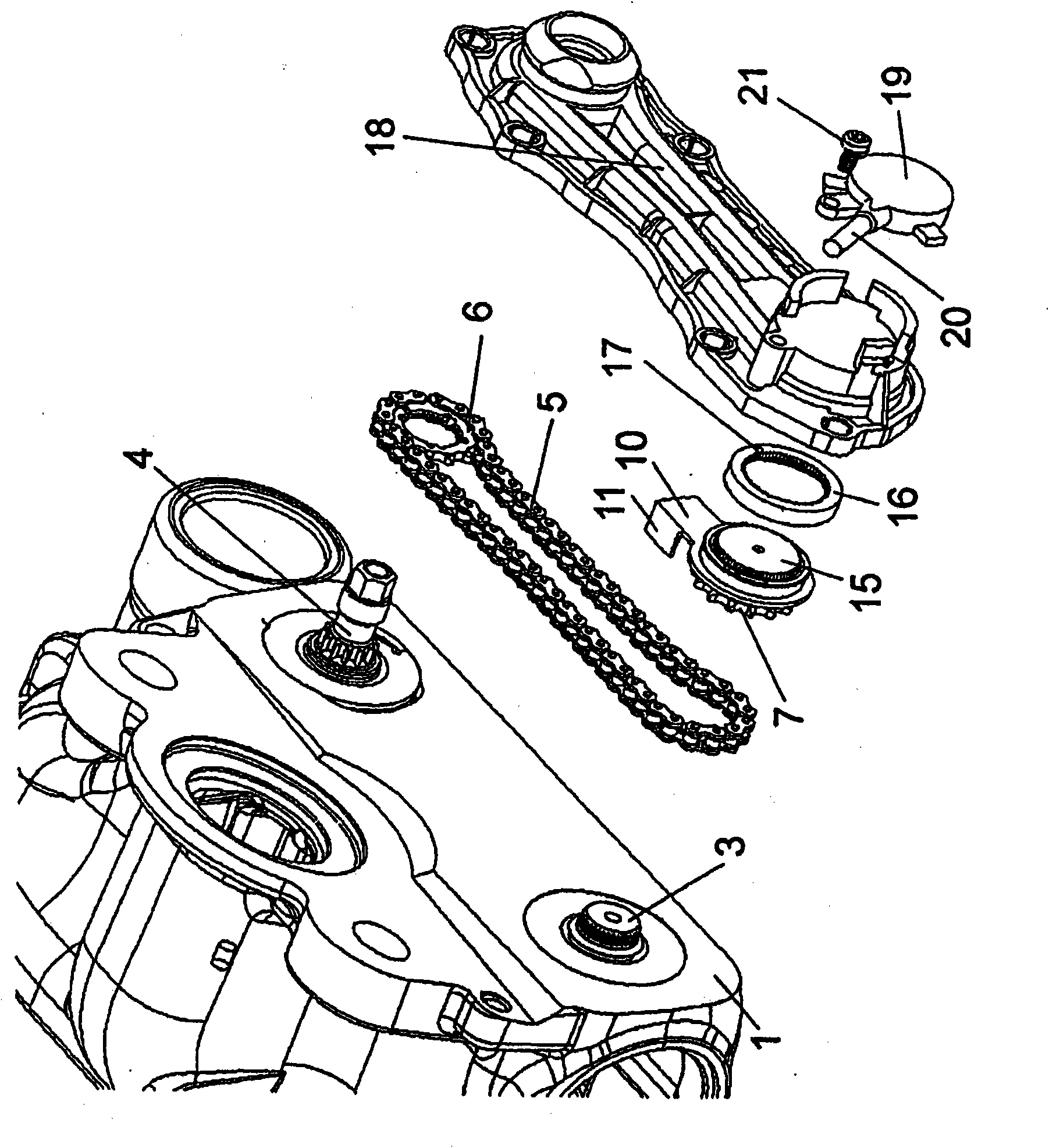

[0025] In order to adjust the adjusting screws 3, 4 synchronously to compensate for the wear path, the two adjusting screws are coupled to each other via a chain drive, which cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com