Full-automatic quartered mold box

A fully automatic, mold box technology, used in mold separation devices, ceramic molding machines, manufacturing tools, etc., can solve the problems of low production efficiency, low degree of automation, high labor intensity, etc., achieve good sealing and thermal insulation, improve The effect of high production efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

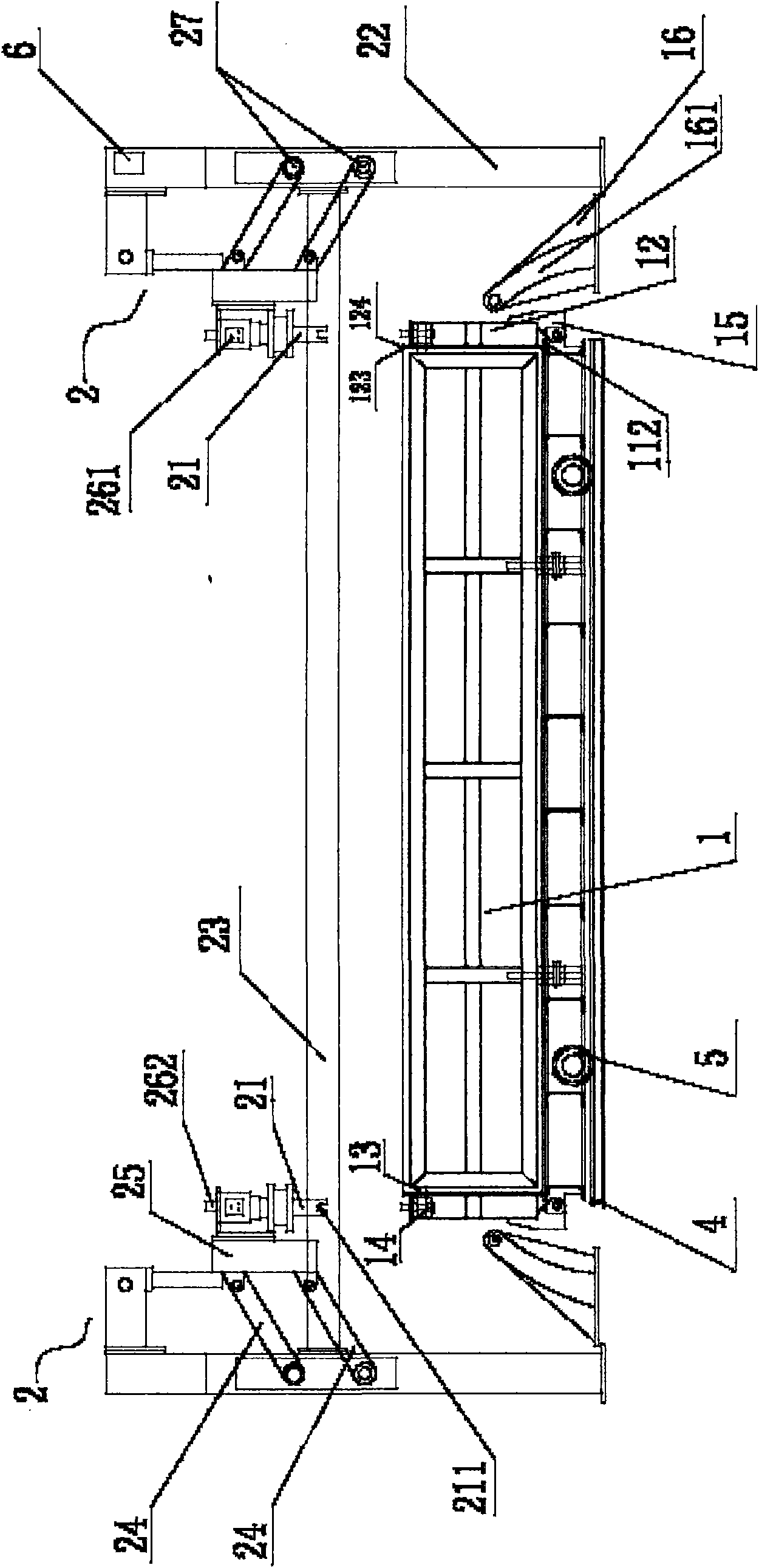

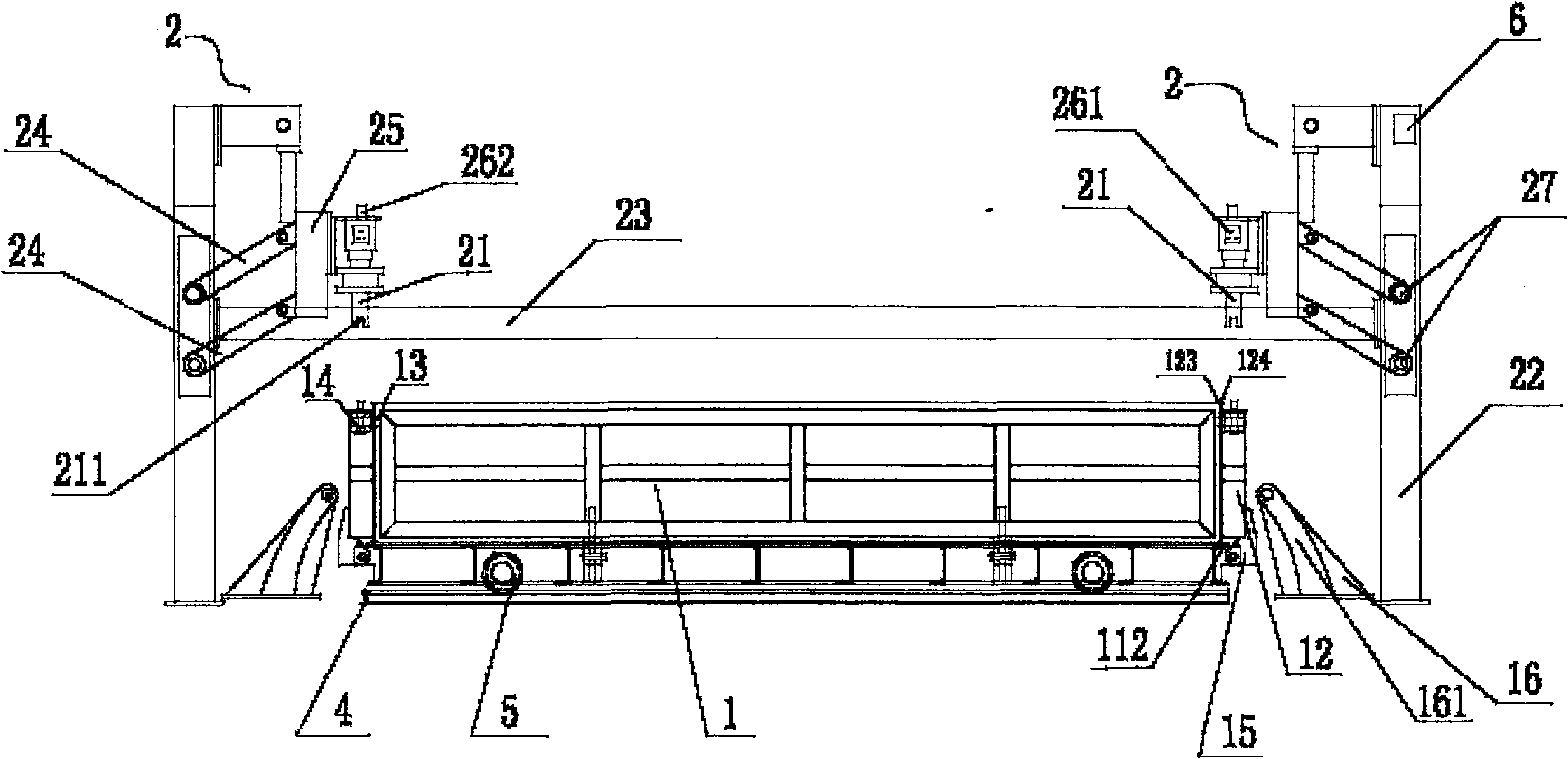

[0025] Please refer to Figure 1 to Figure 2 As shown, the fully automatic four-open mold box of the present invention includes a mold box main body 1, an automatic control switch lock mechanism 2 and a hydraulically supported door opening device 3.

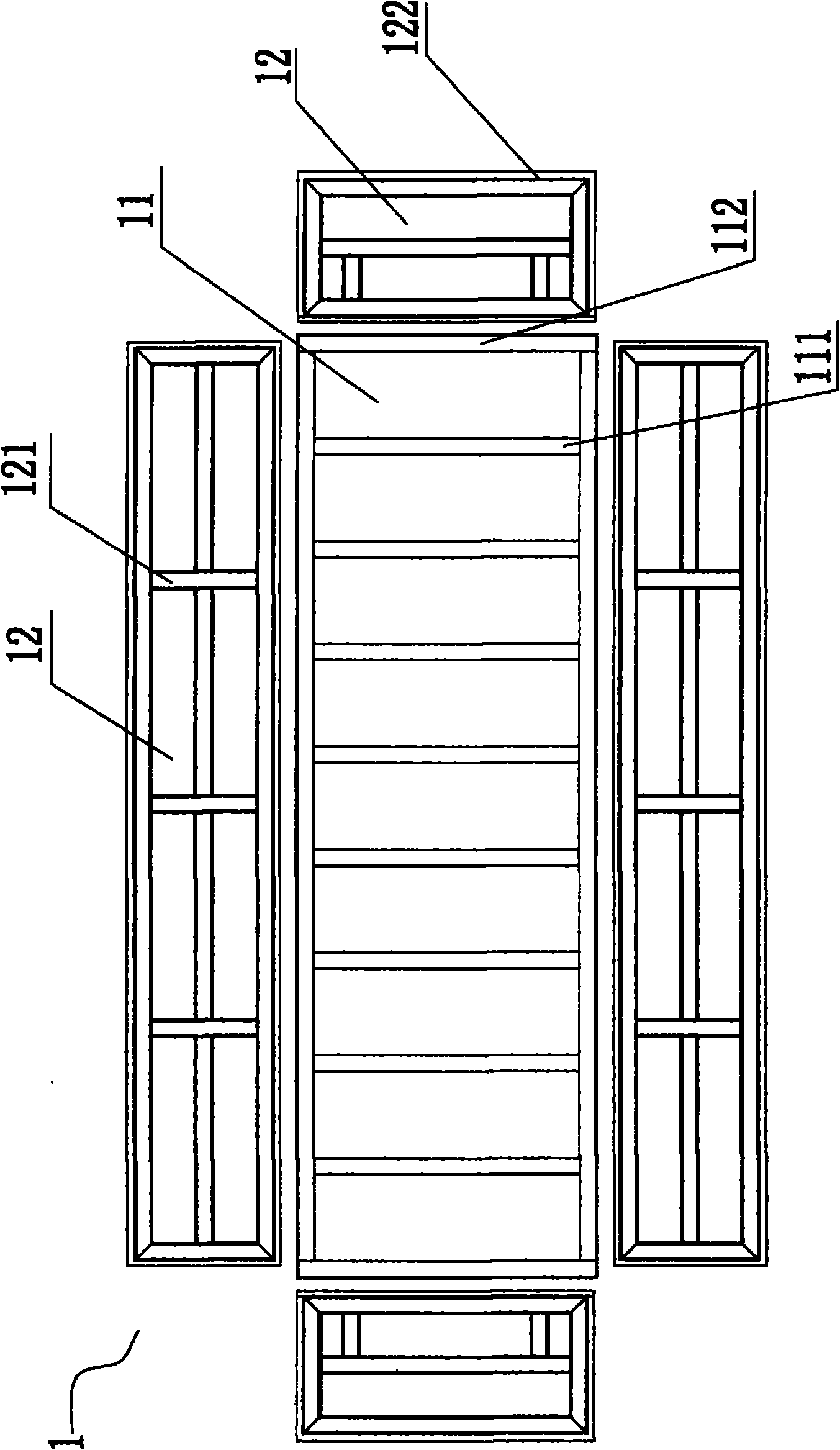

[0026] The mold box main body 1 includes a bottom 11 and a side 12 arranged around the bottom and connected to the bottom. The side 12 closes with the bottom 11 to form a cavity (not shown) for manufacturing an embryo. The bottom 11 includes a bottom frame 111 formed by welded section steel and a bottom plate 112 arranged under the bottom frame and connected to the bottom frame. Attached side panels 122 . The side plate 122 of the main body of the mold box is a structure of double-layer steel plate 123 sandwiching a layer of rubber 124, which can not only play a sealing role but also keep the wet material warm. Between each adjacent two sides 12, be provided with the lock device 13 that connects adjacent side parts together and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com