Gravity mixing bioreactor obliquely rotating along central shaft of culture vessel

A bioreactor and culture bottle technology, which is applied in the field of gravity mixing bioreactors that tilt and rotate along the central axis of the culture container, can solve the problems of easy contamination of microorganisms, heavy labor, and more dirt, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

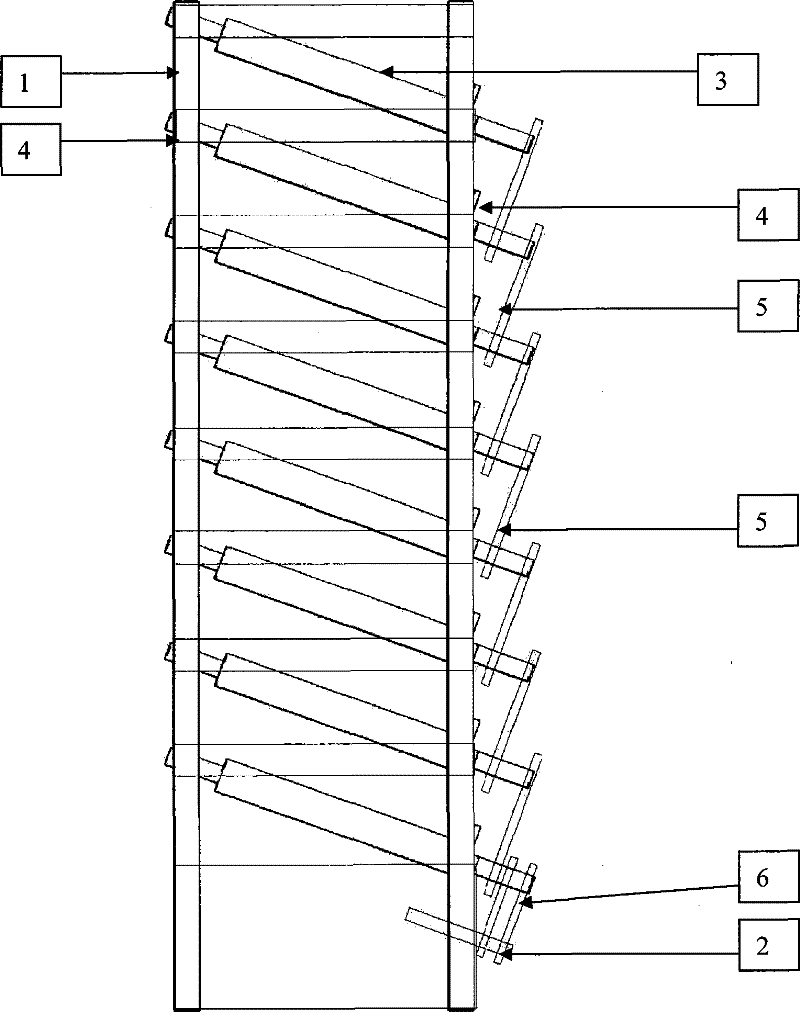

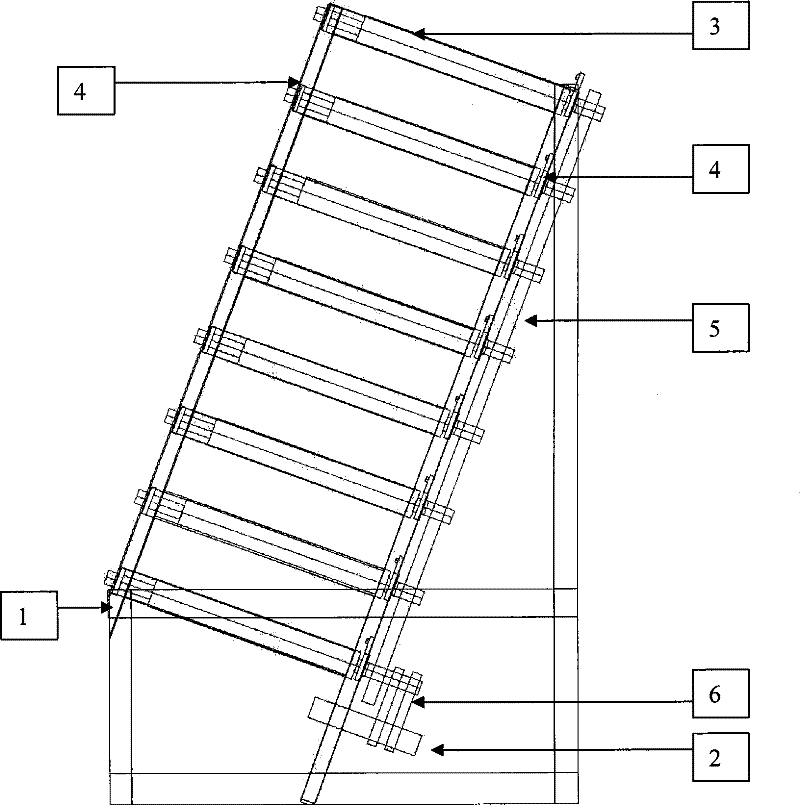

[0015] figure 1 , figure 2 In order to realize the side view of the two models of this design idea, the crossbeam (4) in the frame (1) is connected with one or more rows, one or more columns parallel to each other and 5 to 80 degrees from the horizontal plane. The columnar transmission shaft group (3) of angle, the active rotation columnar transmission shaft of every column or every row cylindrical culture bottle fixing device (3) is connected by belt or gear (5), and is connected to common via belt or gear (6). The motor (2) is controlled by the control circuit to drive the motor to actively rotate the cylindrical drive shaft to rotate.

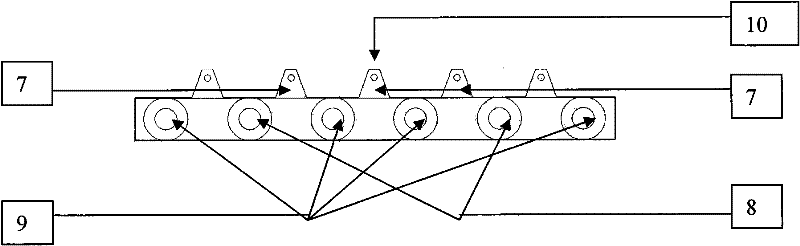

[0016] image 3 It is a front view of a horizontally placed columnar culture vessel fixing device. Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com