Novel construction process for expansion joint of high-speed railway bridge

A high-speed railway and construction technology technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems that cast elastomer materials cannot be bonded well, cannot guarantee the working life of expansion joints, and shorten the service life of bridges, etc., to achieve The construction technology is meticulous, the construction technology is scientific and reasonable, and the service life is prolonged

Inactive Publication Date: 2010-08-18

RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

View PDF0 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This kind of construction method is easy to bond well with the cast elastomer material, resulting in potting that is not resistant to weather aging and potting cracks

The main body of the bridge leaks, and the service life of the bridge is shortened accordingly. However, this kind of sealing layer is at the lowest layer of the bridge, and it is required to have the same life span as the bridge. Once there is a quality problem, it cannot be repaired at all.

In view of the fact that the traditional simple construction technology cannot make the cast elastic body and the bridge interface well bonded, and cannot guarantee the long working life of the expansion joint, and the railway bridge project is a long-term plan for the country, and the quality needs to be improved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

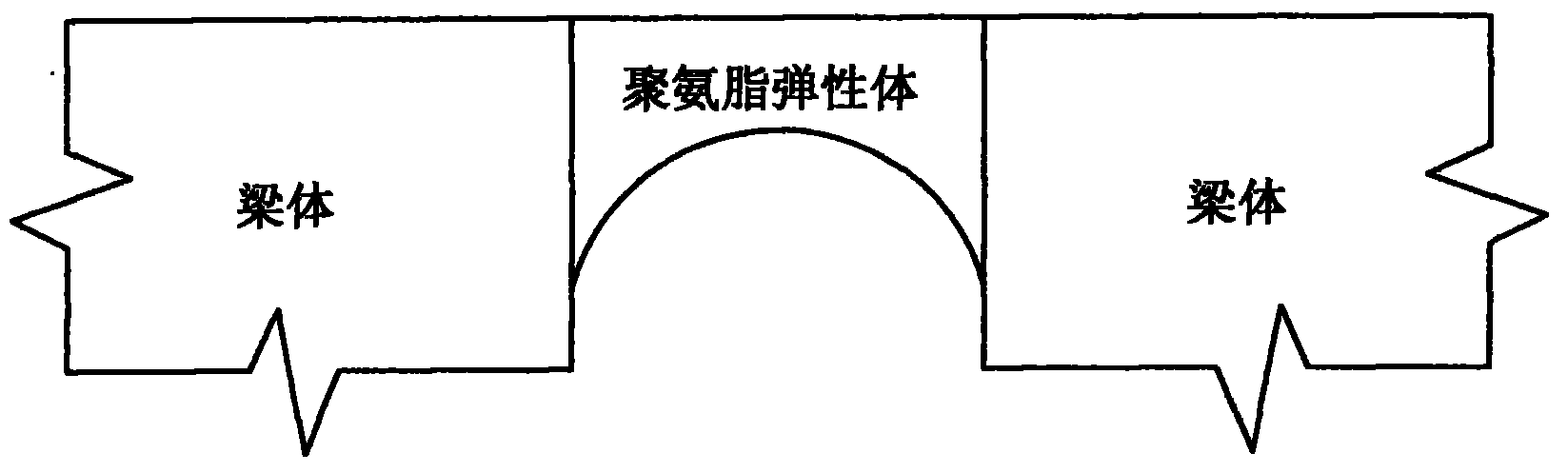

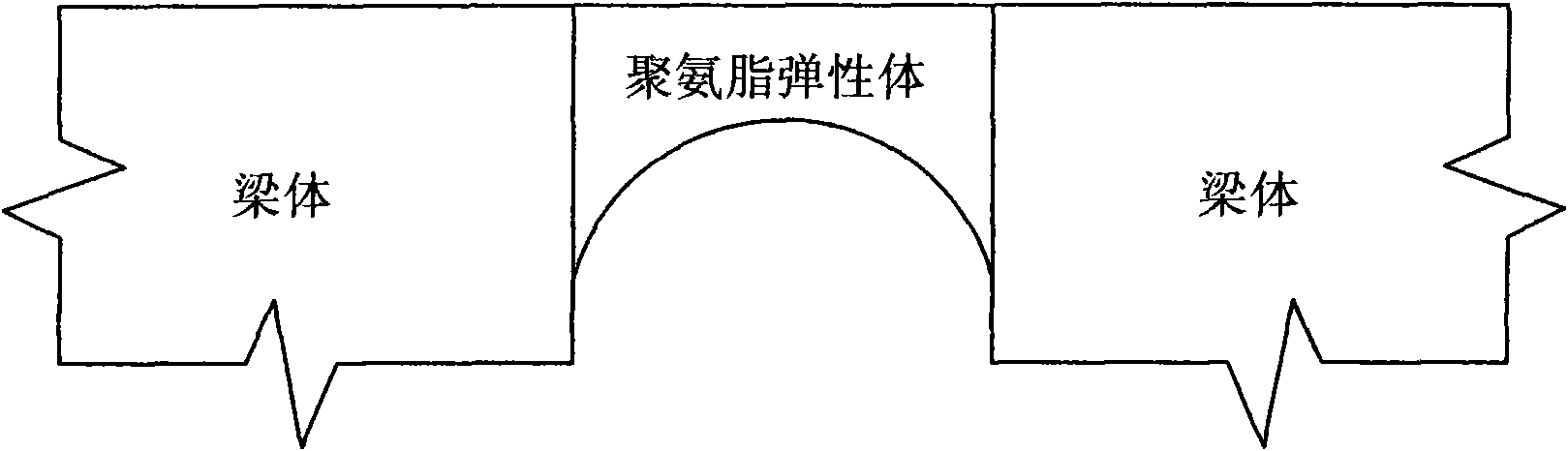

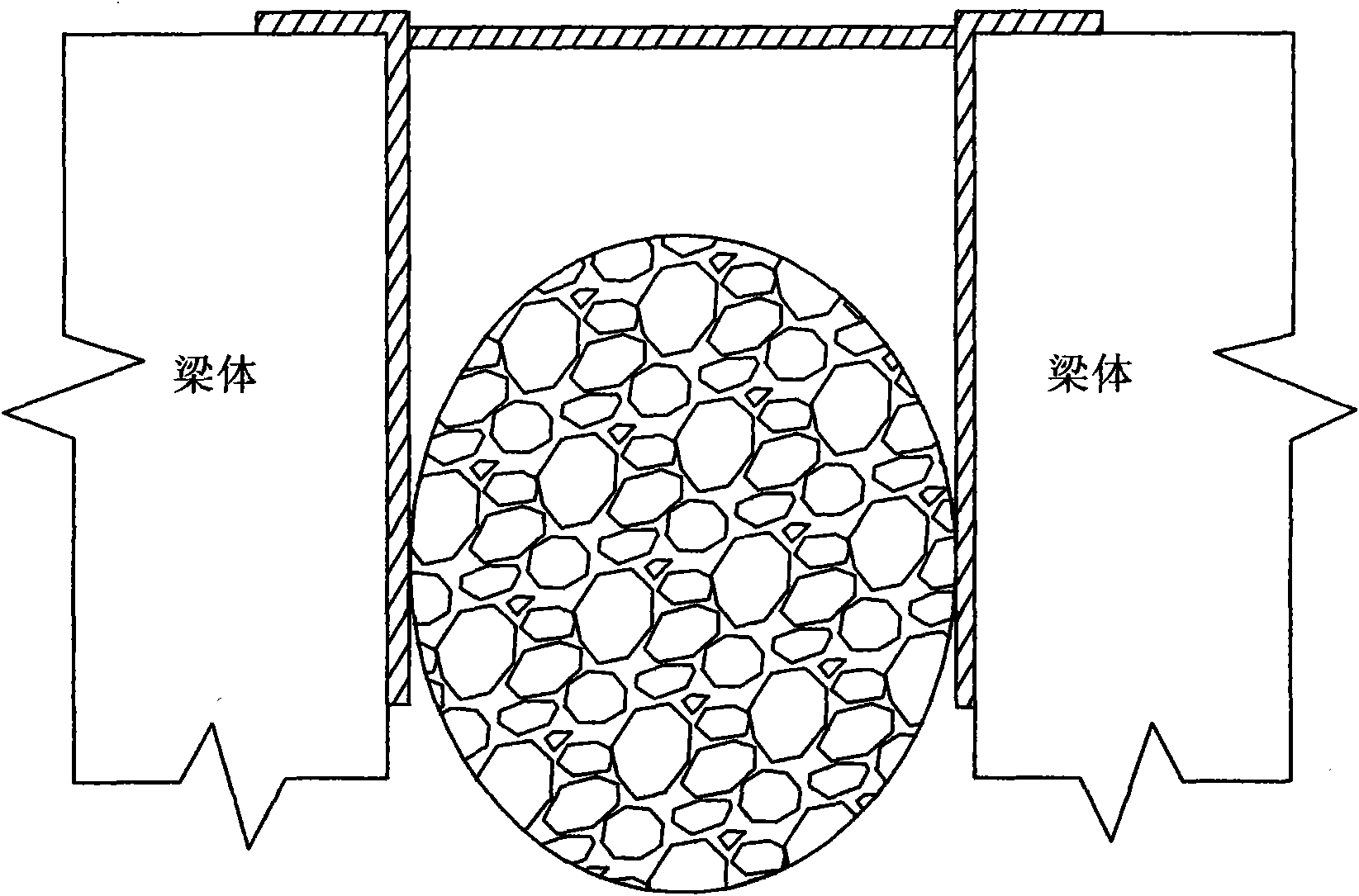

The invention discloses a novel construction process for an expansion joint of a high-speed railway bridge, which relates to a construction process in the field of expansion joint sealing of the high-speed railway bridge. The construction process of the invention comprises following the steps: expansion joint treatment, primer preparation and brush coating, potting adhesive preparation and injection forming, curing and detection. The construction process is scientific and reasonable, greatly improves the functions of the expansion joint and greatly prolongs the service life of the expansion joint; the construction process is fine, has perfect bedding surface treatment, and improves the bonding strength of the expansion joint by more than 5 times as compared with the traditional process; and higher bonding strength between the expansion joint and the concrete interface can be obtained to play a waterproof function.

Description

A new construction technique for expansion joints of high-speed railway bridges Technical field: The invention relates to a construction technique in the field of sealing expansion joints of high-speed railway bridges, in particular to the improvement of the construction technique for pouring polyurethane elastomer materials into the expansion joints of existing high-speed railway bridges. Background technique: When building high-speed railway bridges, in order to adapt to the deformation of the bridge surface when it expands with heat and contracts with cold, expansion joints of a certain size are left, and a polyurethane liquid elastic material is poured into the expansion joints to protect the bridge. The traditional construction technology basically does not deal with the concrete interface of the main body of the bridge, and the end seal materials at both ends of the potting are mostly steel, plate, rubber, etc., and the method of direct pouring is adopted. Such a con...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E01D19/06

Inventor 牛斌马林王乐然陈强胡所亭张万明安振清

Owner RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com