Automatic following support system and method

A technology that automatically follows and supports the system. It is used in building maintenance, construction, building construction, etc. It can solve problems such as poor safety, low construction efficiency, and high labor intensity of workers, so as to avoid slippage, improve project safety, and provide engineering The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

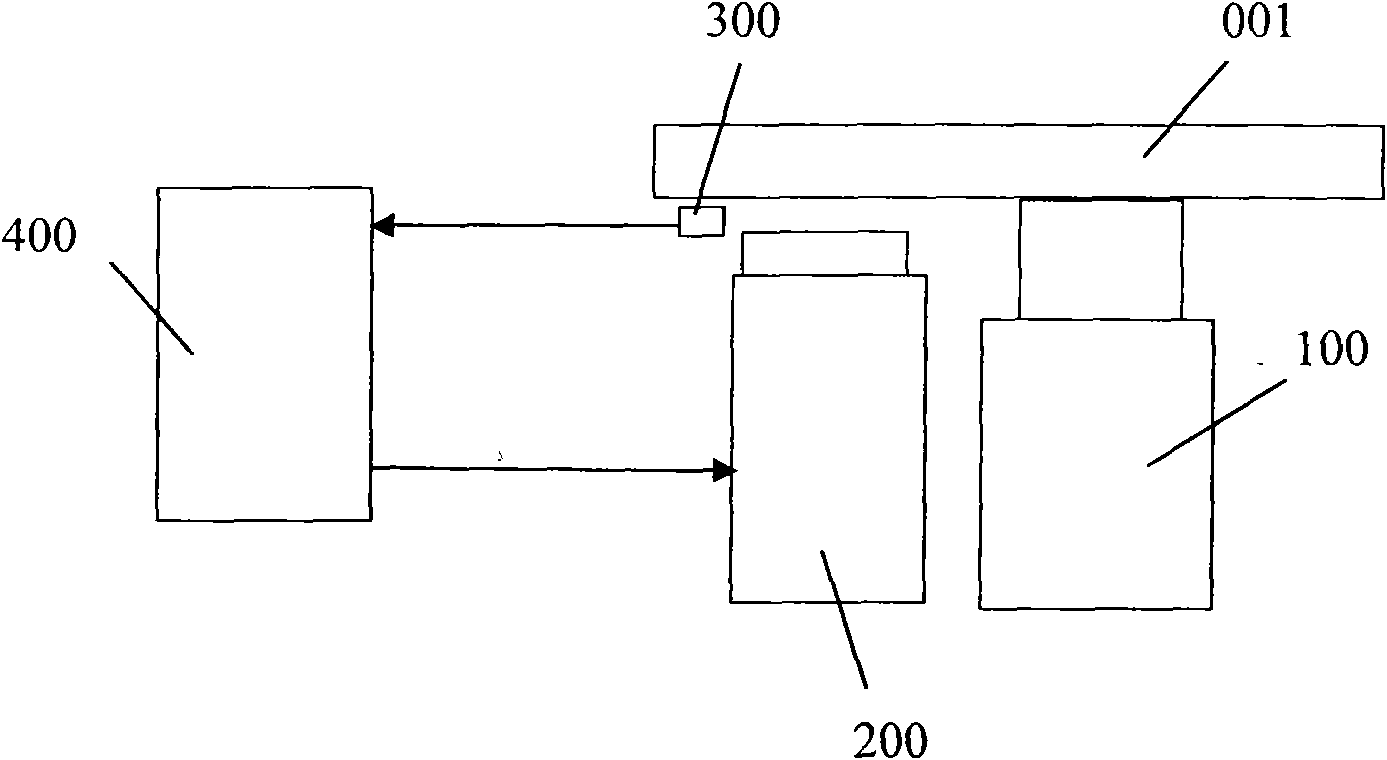

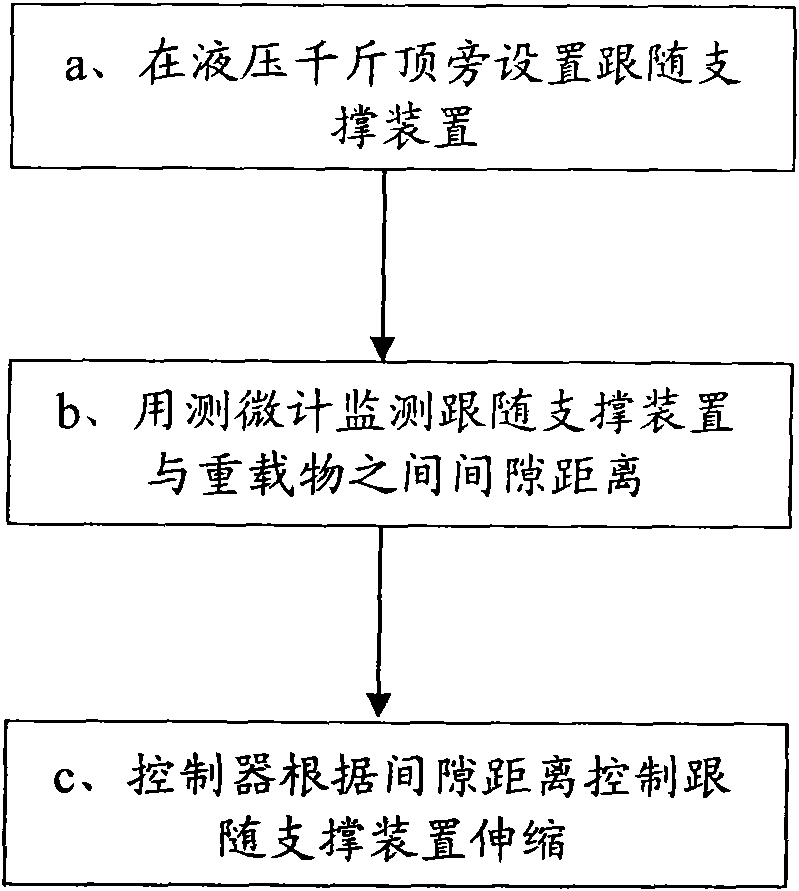

[0024] Such as figure 1 As shown, the automatic follow support system of the present invention includes a hydraulic jack 100 , a follow support device 200 , a micrometer 300 , and a controller 400 .

[0025] Among them, the hydraulic jack 100 is used to lift heavy loads;

[0026] Following the support device 200, it is arranged next to the hydraulic jack 100, and is used to temporarily support the heavy load 001 when the hydraulic jack 100 fails unexpectedly to ensure the safety of jacking;

[0027] The micrometer 300 is arranged next to the top of the following support device 200, and is used to monitor the gap distance between the following support device 200 and the heavy load 001;

[0028] The controller 400 controls the expansion and contraction of the following support device 200 according to the gap distance measured by the micrometer 300 .

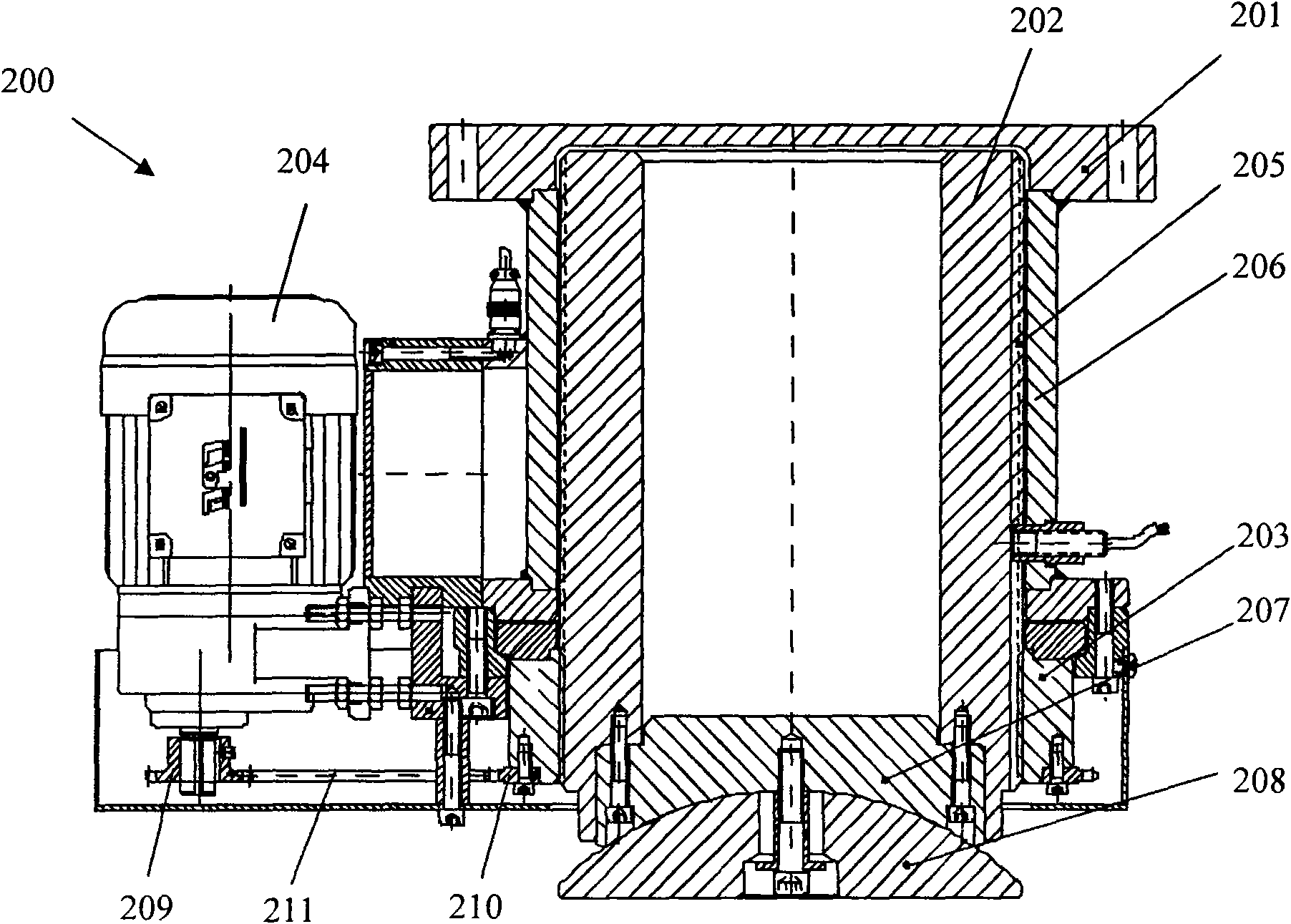

[0029] in such as figure 2 As shown, the following support device 200 includes a jacking plate 201 , a screw 202 , a nut 203 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com