Safety test box of battery pack

A technology for safety testing and battery packs, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as limited capacity, and achieve the effect of good safety performance and flexible and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

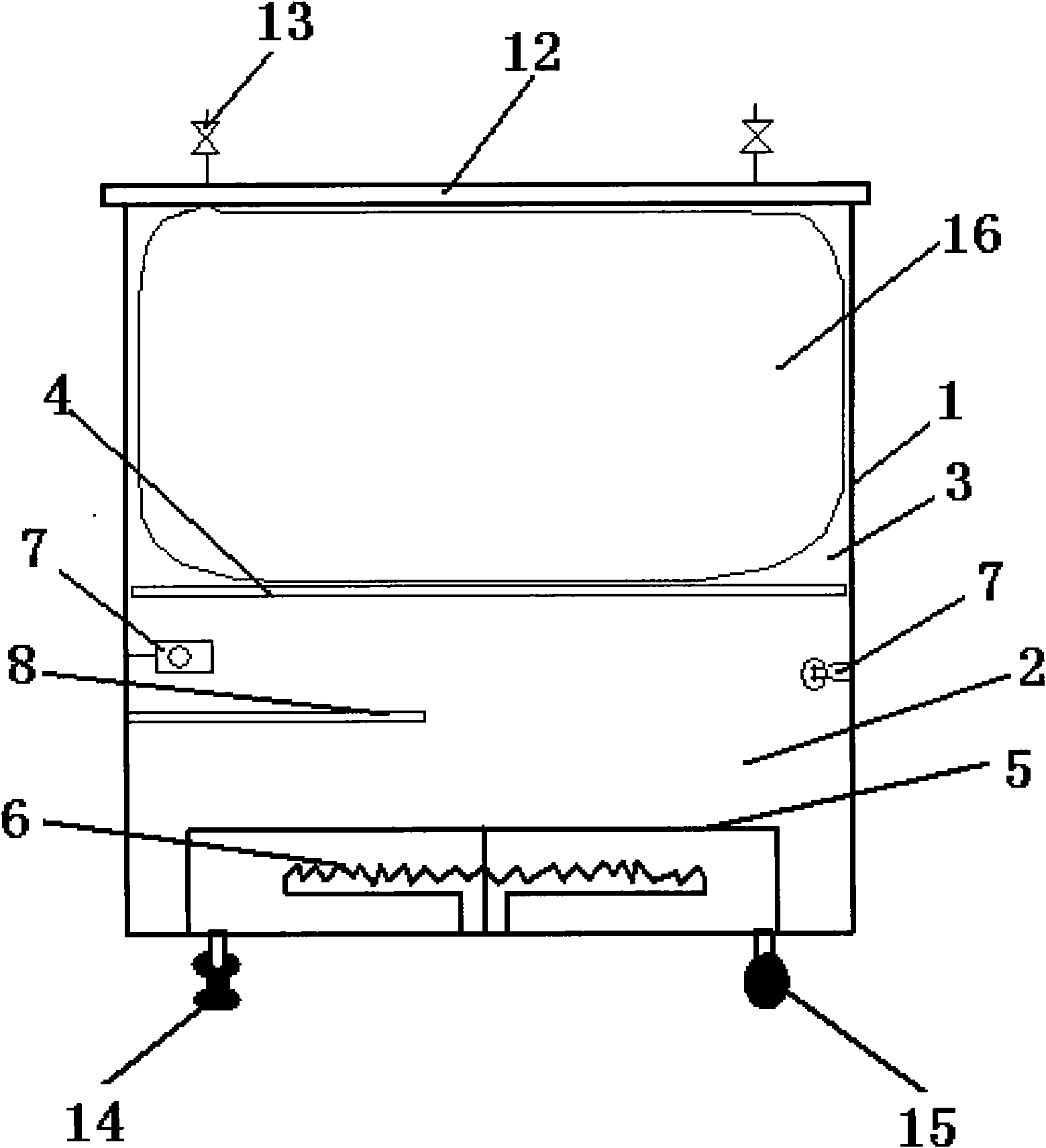

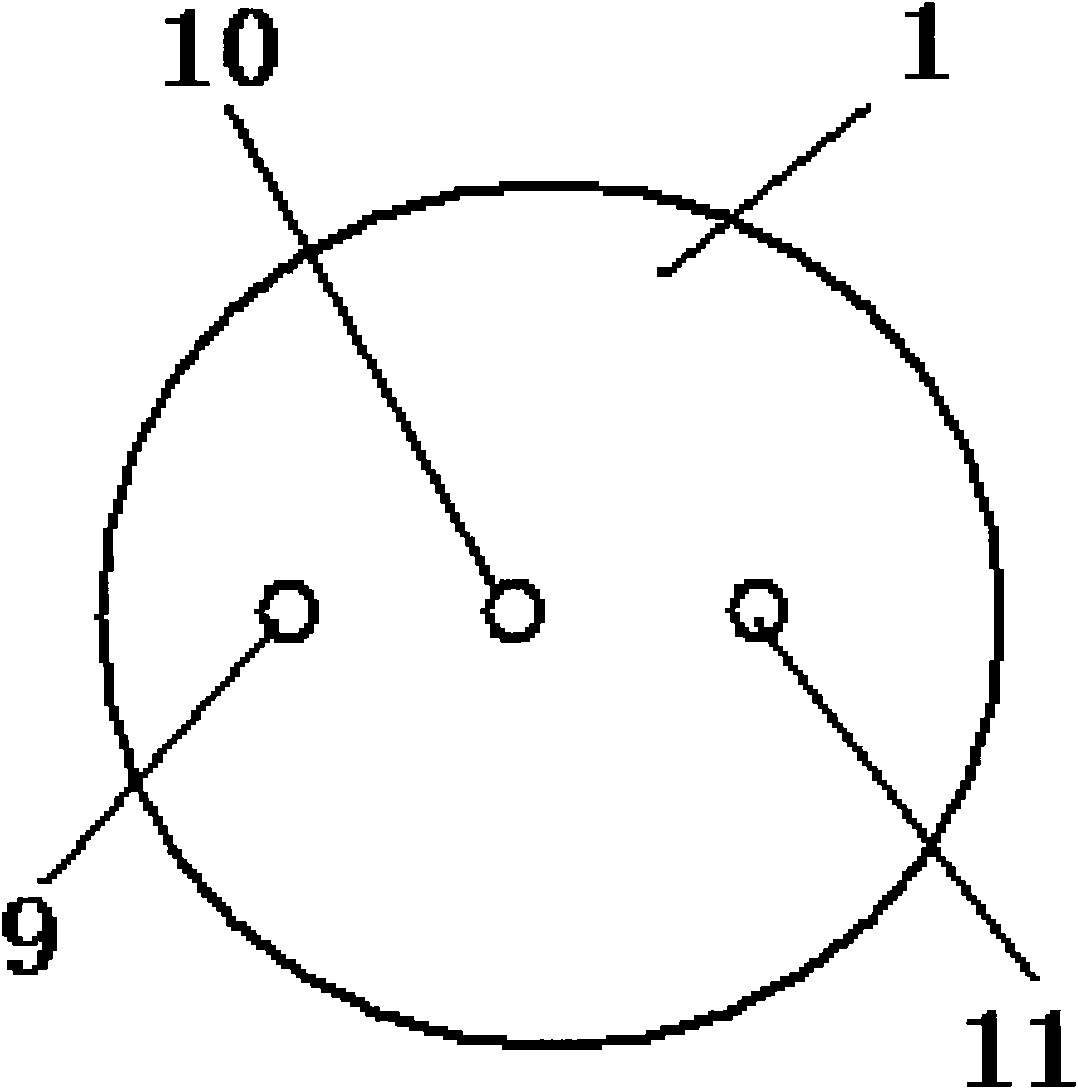

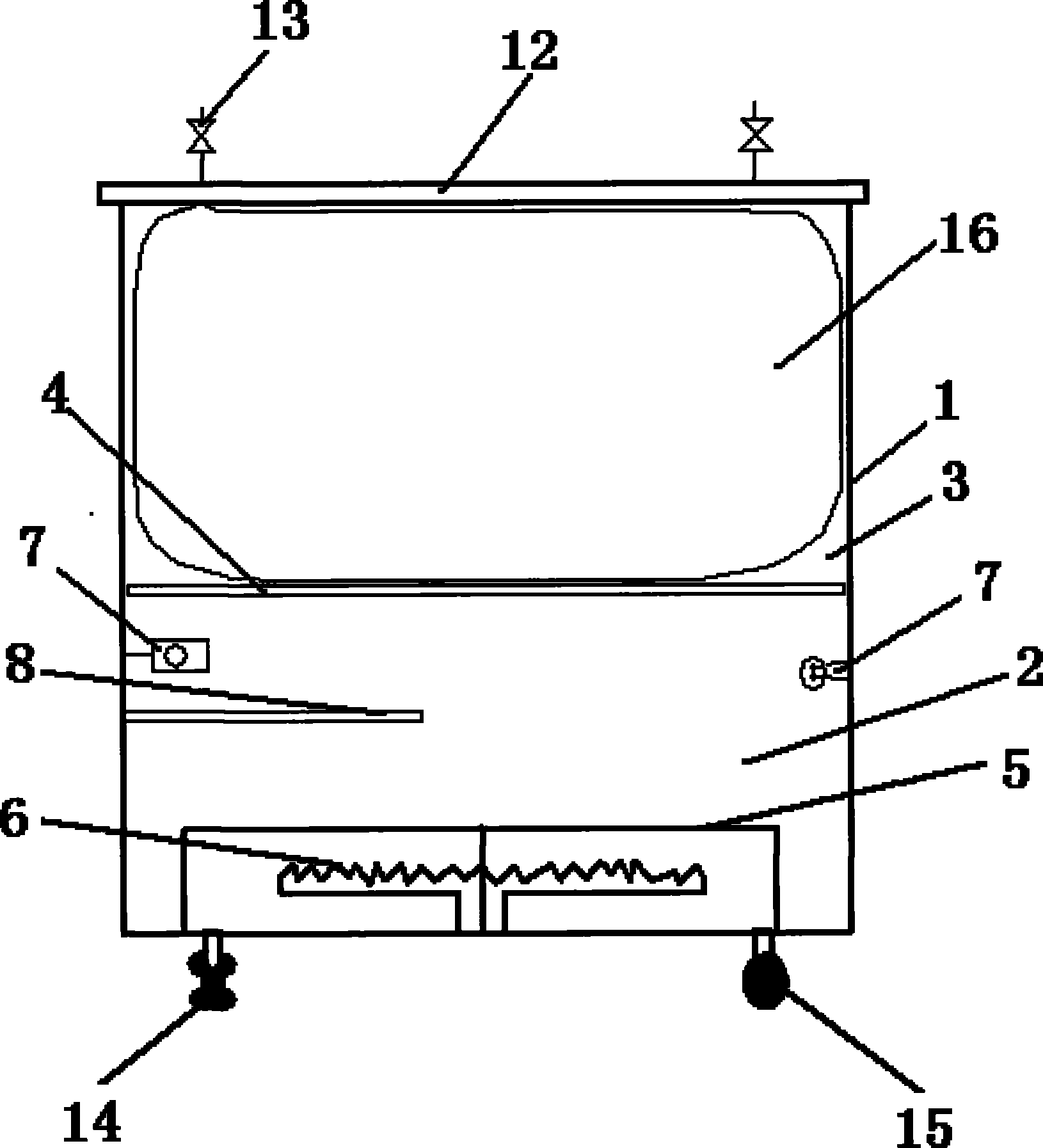

[0021] Example: such as figure 1 and figure 2 As shown, a battery pack safety test box includes a cylindrical airtight box 1 , and the inside of the airtight box 1 is divided into a battery pack safety test chamber 2 and an air chamber 3 by a partition 4 . The battery pack safety test chamber 2 is located below the air chamber 3, and the partition plate 4 can move freely up and down. Among them, the airtight box 1 and the partition 4 are made of special steel plates with a thickness of 1mm~10mm, which can effectively prevent the shock wave stress generated when the battery pack may explode. .

[0022] The airtight box 1 is provided with a detachable top cover 12 above the air chamber 3 , and two pressure relief valves 13 are provided on the top cover 12 .

[0023] The air chamber 3 is provided with a safety airbag 16 , and the opening of the safety airbag 16 communicates with the pressure relief valve 13 .

[0024] The volume of the air chamber 3 is more than five times t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com