Inner wall fused and embedded single-mode polarization maintaining fiber grating and preparation method thereof

A polarization-maintaining optical fiber and single-mode technology, which is applied in the direction of polarization optical fiber, cladding optical fiber, optical waveguide light guide, etc., can solve the problems of inconvenient research and complicated preparation process of side-hole optical fiber, and achieve the effect of good polarization maintaining characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

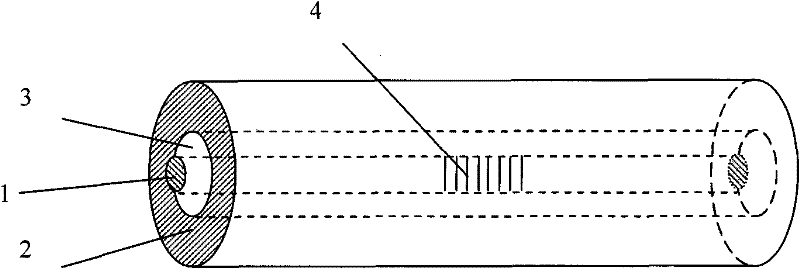

[0030] combine image 3 A schematic diagram of a device for making an inner-wall fusion-embedded single-mode polarization-maintaining fiber grating according to the present invention.

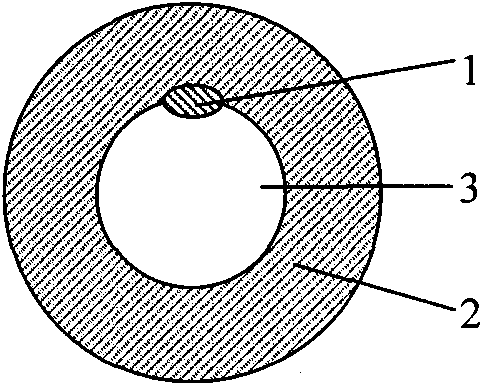

[0031] The air hole of the present invention is circular and coaxial with the cladding (Fig. 2(a)) The embodiment of the manufacturing method of the single-mode polarization-maintaining fiber grating fused to the inner wall, specifically includes the following steps:

[0032] ①. A polarization-maintaining optical fiber 5 whose air hole is circular and coaxial with the cladding carries hydrogen for one cycle, strips off the coating layer of the optical fiber with a length of 3-4 cm, and fixes it on the optical fiber holder after cleaning. Observe the position of the major and minor axes of the fiber core with a microscope;

[0033] ②. In order to reduce the birefringence introduced by ultraviolet exposure, adjust the multi-dimensional adjustment device so that the long axis of the optical fiber...

Embodiment approach 2

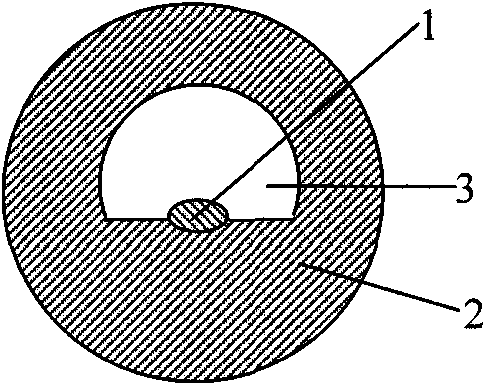

[0039] The embodiment of the manufacturing method of the D-type air hole inner wall fusion-embedded single-mode polarization-maintaining fiber grating specifically includes the following steps:

[0040] ①. A single-mode polarization-maintaining optical fiber fused to the inner wall of a D-shaped air hole (Fig. 2(b)) carries hydrogen for one cycle, and strips off the coating layer of the optical fiber with a length of 3-4cm. For better polarization maintenance, the The polarization-maintaining fiber is ground into a D-shaped fiber 9 along the direction of the D-shaped air hole (see Figure 4 );

[0041] ②. After cleaning, fix it on the optical fiber fixture, and use a microscope to observe the position of the long and short axes of the fiber core;

[0042] ③. Adjust the multi-dimensional adjustment device so that the polished surface of the D-type optical fiber is parallel to the phase mask 8, adjust the phase mask 8 to be close to the optical fiber 9, and fix it after adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com