Automatic identification system for surgical cutter

A surgical operation and self-identification technology, which is applied in the field of self-identification system, can solve the problems of increasing the work intensity of doctors, prolonging the operation time, and increasing the risk of surgery, so as to avoid the operation risk and shorten the operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

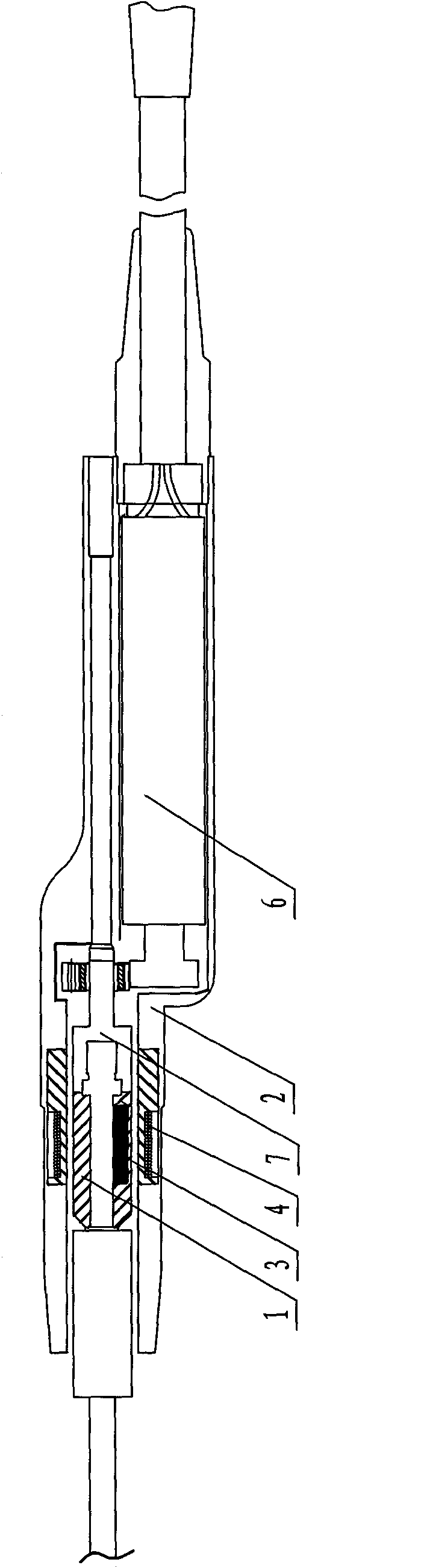

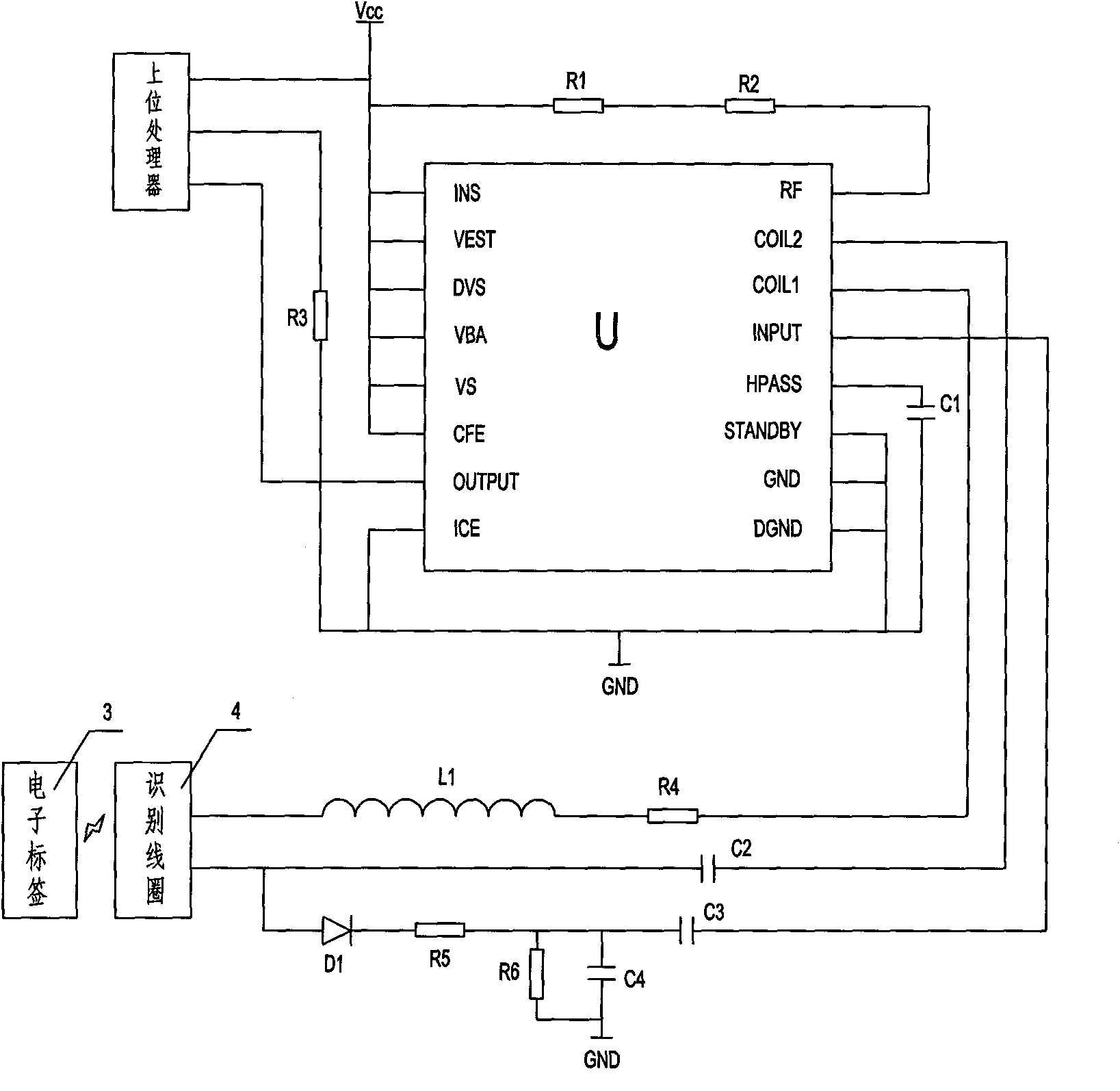

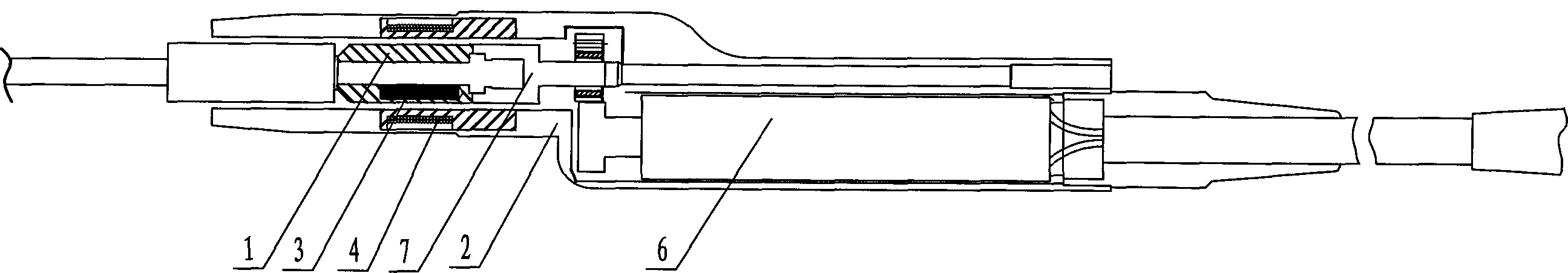

[0033] Such as figure 1 Shown: a self-identification system for surgical knives, including an external knife and a controller, wherein the external knife is provided with a plug 1, the controller is provided with a socket 2 and a processing circuit, and the external knife and the controller are connected through the plug 1, The socket 2 is assembled and connected, and the key is that an electronic tag 3 is installed on the plug 1, an identification coil 4 is installed on the socket 2, the identification coil 4 is connected to the processing circuit, and the identification coil 4 obtains the electronic tag 3 After receiving the electromagnetic information, a signal is sent to the processing circuit, the output end of the processing circuit is connected to the input end of the control motor 6, and the output shaft of the control motor 6 is connected to the external tool.

[0034] Each type of external tool is respectively configured with a corresponding radio frequency signal in...

Embodiment 2

[0058] Embodiment 2 The plug 1 and the socket 2, the electronic tag 3 and the identification coil 4 are installed at the junction of the control motor 6 and the transmission cable.

Embodiment 3

[0059] Embodiment 3 The plug 1 and the socket 2, the electronic label 3 and the identification coil 4 are installed on the casing of the controller, that is, the junction of the controller and the transmission cable.

[0060] Its specific structure is as follows:

[0061] Example 2:

[0062] The handle end of the external tool is connected to the output shaft of the control motor 6;

[0063] The control motor 6 is fixedly connected to the plug 1, the plug 1 is a non-metallic plug 1, and a radio frequency card installation hole is also arranged in the plug 1, and the electronic tag 3 is fixed in the radio frequency card installation hole;

[0064] There is a circle of coil installation holes in the socket wall of the socket 2, and the identification coil 4 is set in the coil installation holes. When the plug 1 is inserted into the socket 2, the radio frequency card extends into the identification coil 4.

[0065] Example 3:

[0066] The socket 2 is fixed on the shell of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com