Anti-vibration hammer for high-voltage power transmission lines

A high-voltage transmission line, anti-vibration hammer technology, applied in mechanical vibration damping devices and other directions, can solve the problems of difficult to eliminate water and ice deposition, bulky shape, tip discharge, etc., to achieve great practical and popular value, good vibration reduction effect, The effect of preventing fatigue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

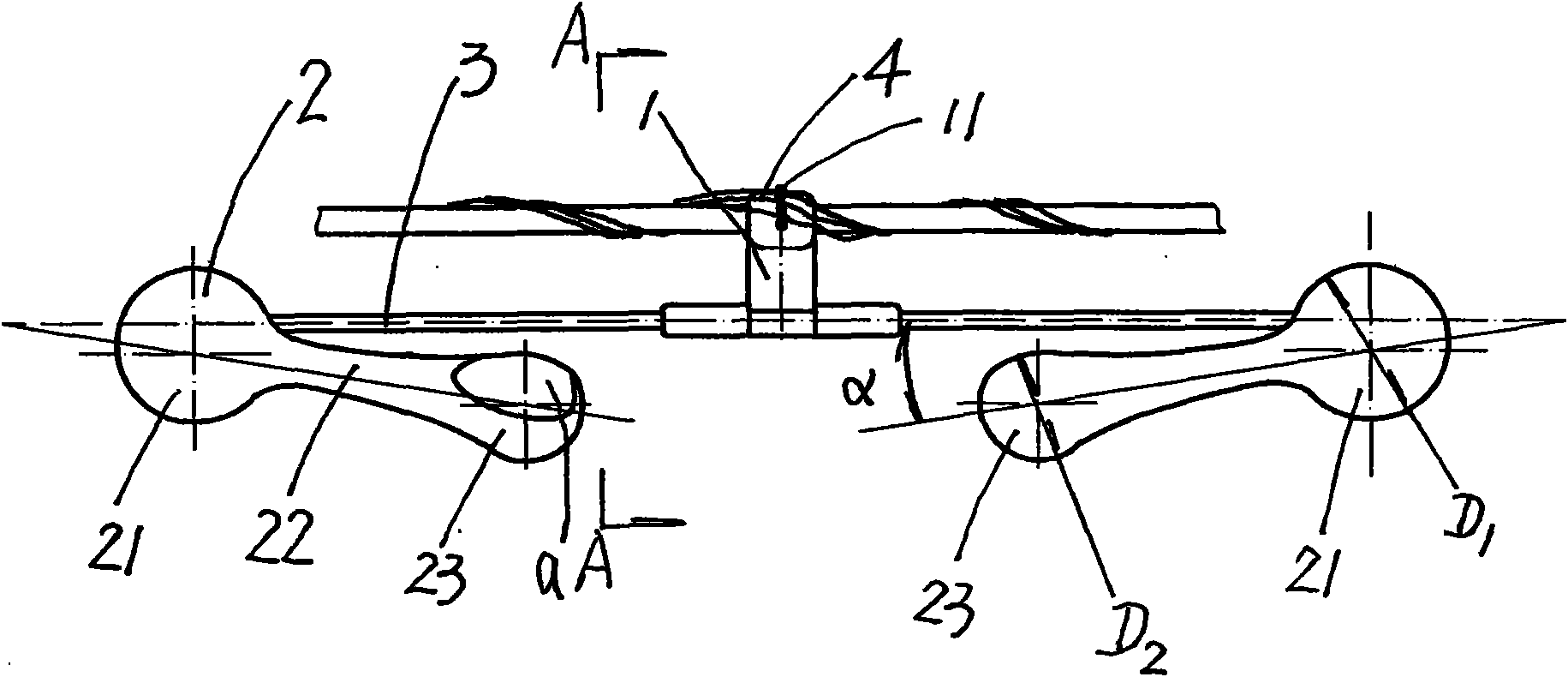

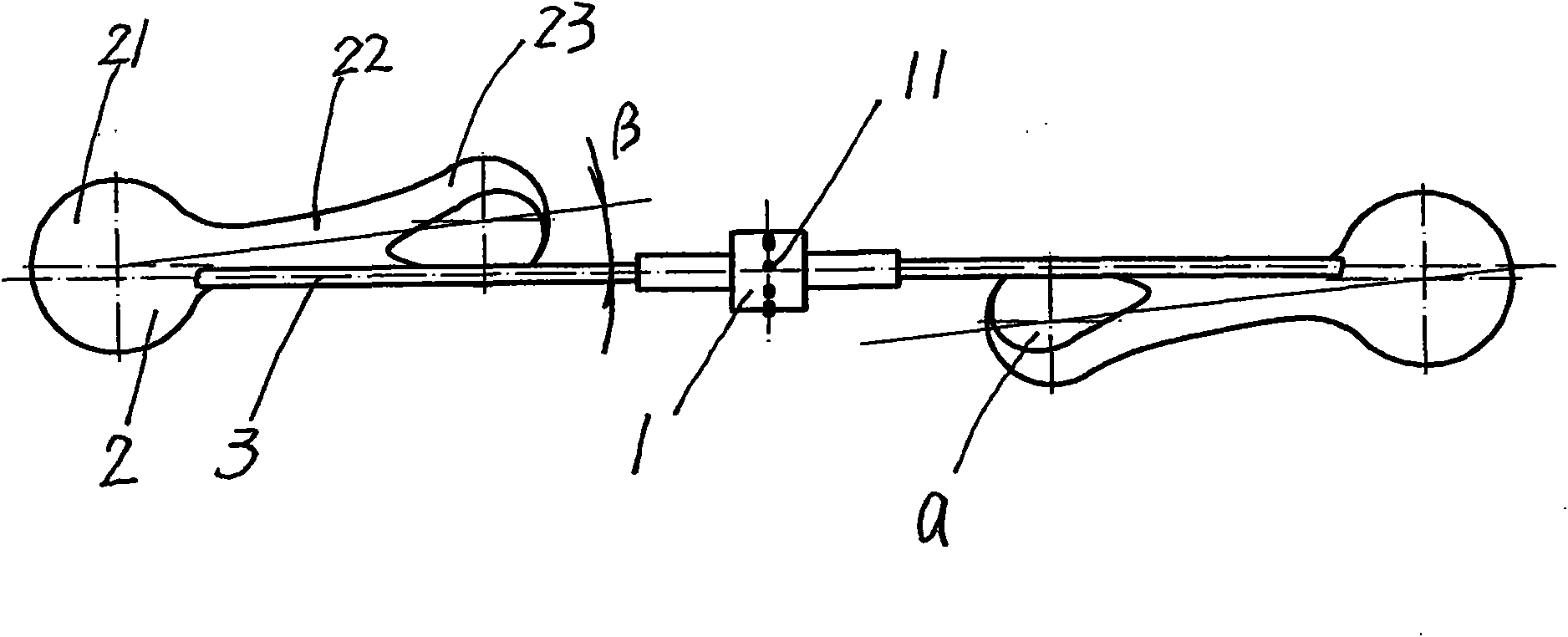

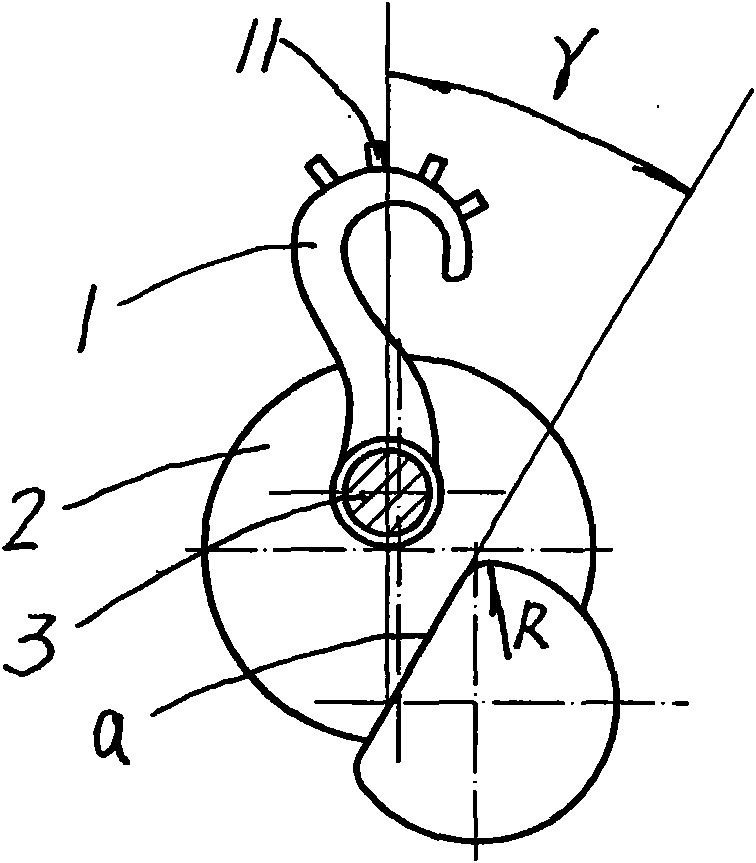

[0015] Refer to attached figure 1 , attached figure 2 , attached image 3 , the anti-vibration hammer for high-voltage transmission line of the present invention is made up of wire clip 1, hammer body 2, steel strand 3, at least one pre-twisted wire 4, and the pre-twisted wire 4 of the present embodiment is three; The stranded wire 3 is fixedly connected, and the two hammer bodies 2 are respectively fixedly installed at both ends of the steel stranded wire 3. The pre-twisted wire 4 is used to fix the wire clamp 1 on the transmission line, and the wire clamp 1 is a hippocampal structure. Form, there are 1 to 6 spacer nails 11 on the clamp 1, the number of spacer nails 11 in this embodiment is 4; the hammer body 2 is a dumbbell-shaped structure, and the two hammer bodies 2 are symmetrically inclined and fixed on the steel On the two ends of stranded wire 3; , cantilever end hammer head 23, the angle α between the connection line between the fixed end hammer head 21 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com