Classification device, standing pulverizer using the classification device, and coal burning boiler apparatus

A classification device, vertical technology, applied in solid separation, chemical instruments and methods, separation of solids from solids by air flow, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

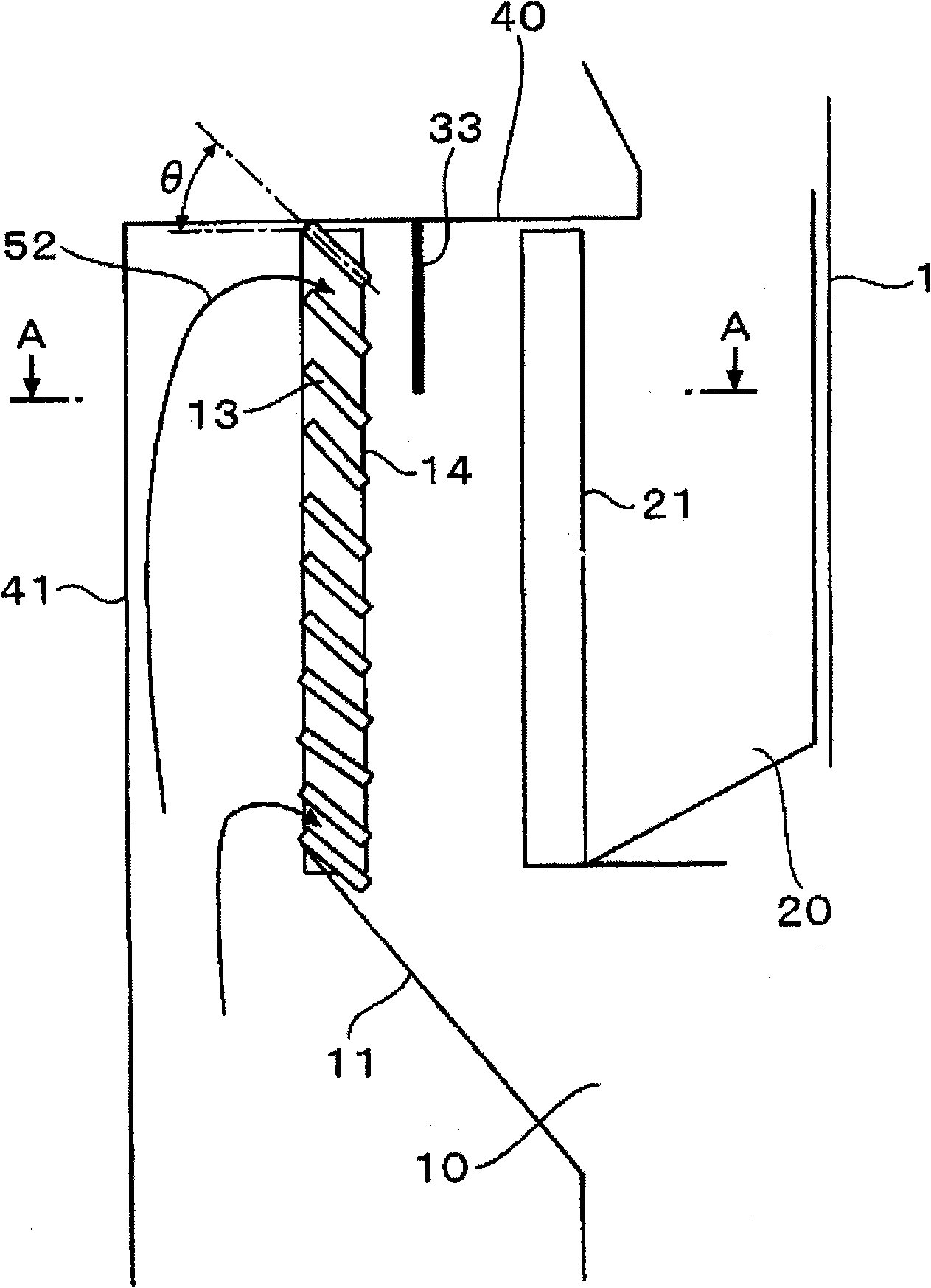

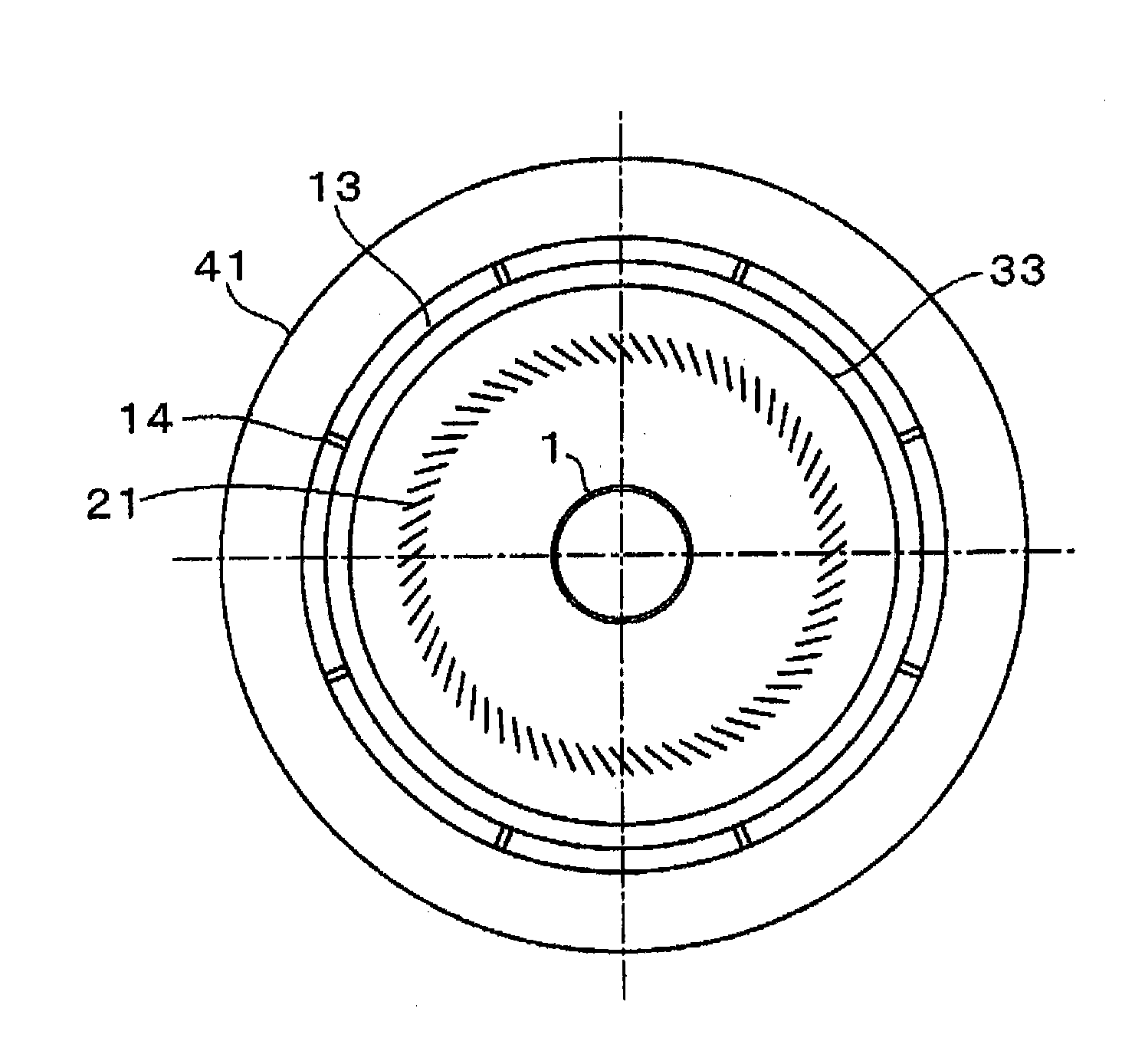

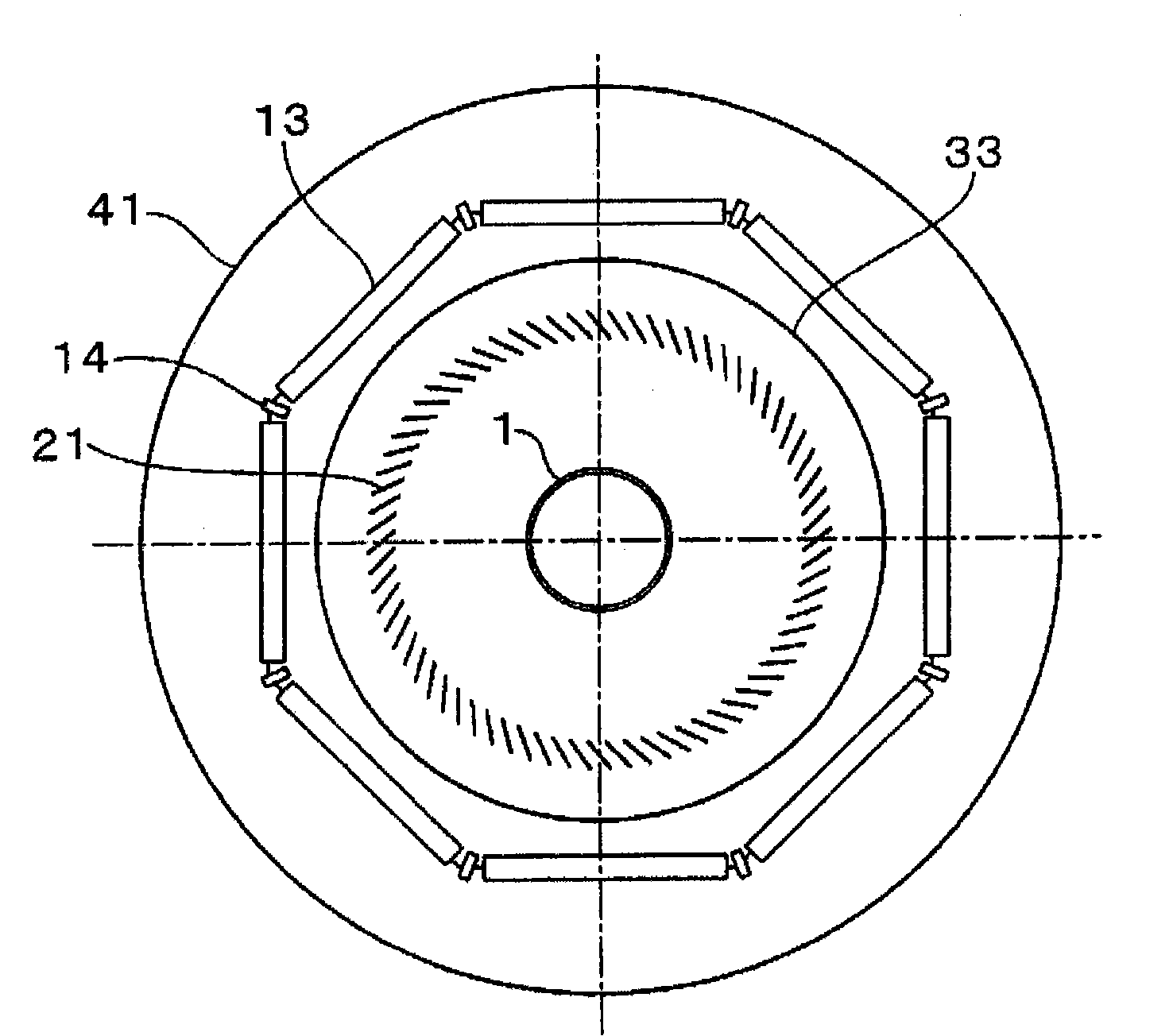

[0042] Next, embodiments of the present invention will be described with reference to the drawings. Figure 1 to Figure 3 is a diagram for explaining the classifying device according to the first embodiment of the present invention, figure 1 It is a schematic longitudinal sectional view showing the main part of the classification device, figure 2 yes figure 1 A schematic cross-sectional view on line A-A of image 3 Indicates a modified example of a fixed fin figure 1 A schematic cross-sectional view on line A-A of . In addition, the schematic structure and Figure 27 The devices shown are the same, so their description is omitted.

[0043] Such as figure 1 As shown, the classifier is a two-stage classifier in which a substantially cylindrical stationary classifier 10 disposed on the inlet side of the classifier and a rotary classifier 20 disposed therein are combined.

[0044] Stationary classifier 10 comprises: long plate-shaped supporting part 14; figure 2 The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com