Patents

Literature

31results about How to "Reduce purification load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

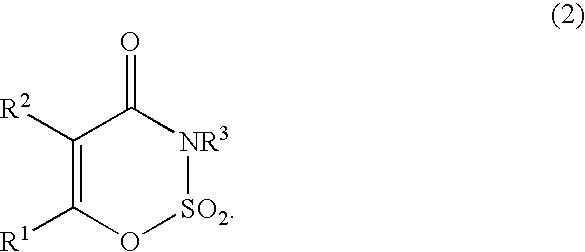

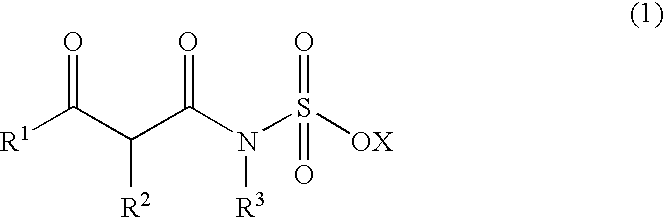

Method for producing 3,4-dihydro-1,2,3-oxathiazin-4-one-2,2-dioxide compound or salt thereof

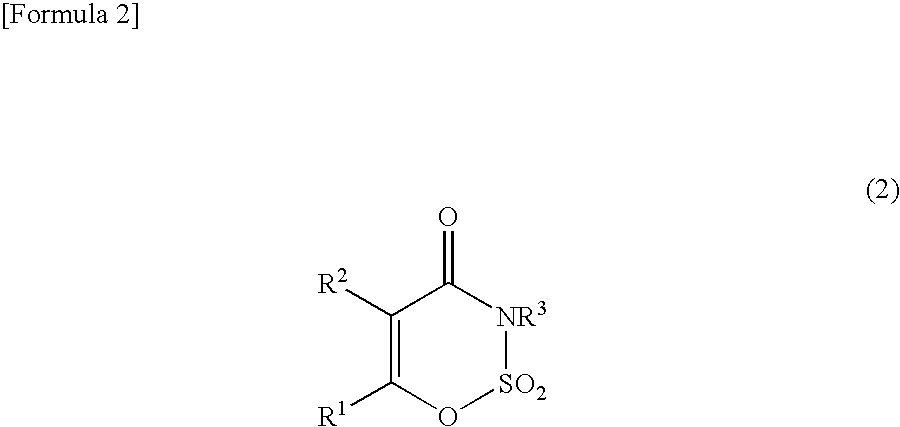

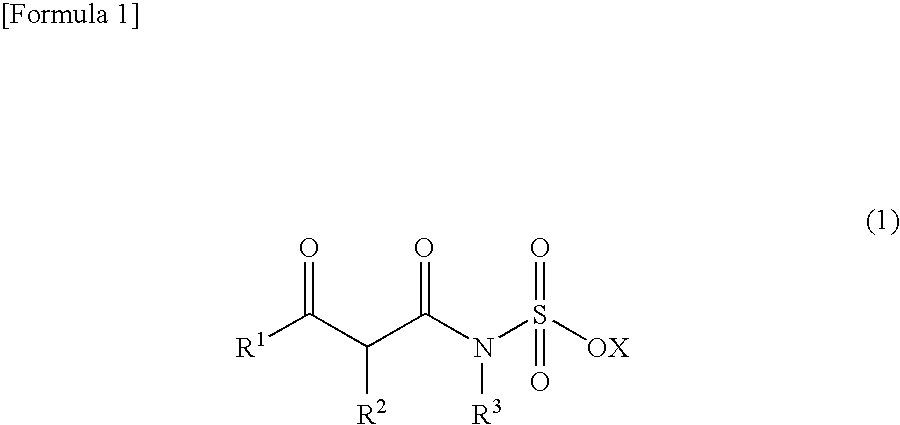

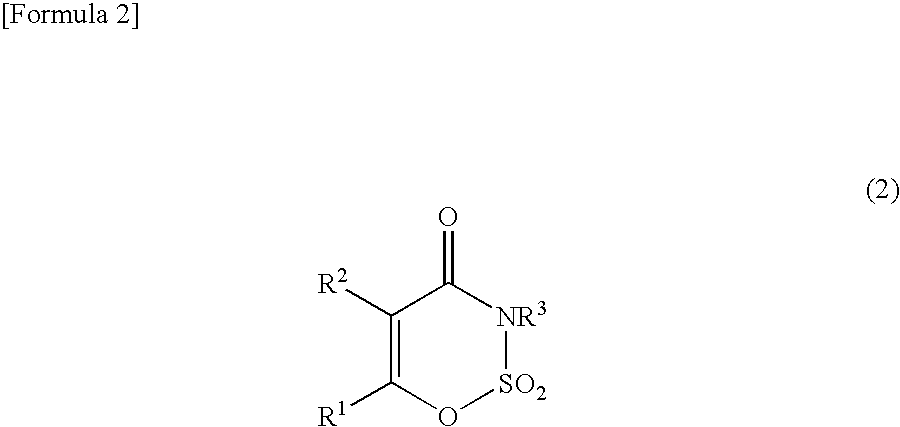

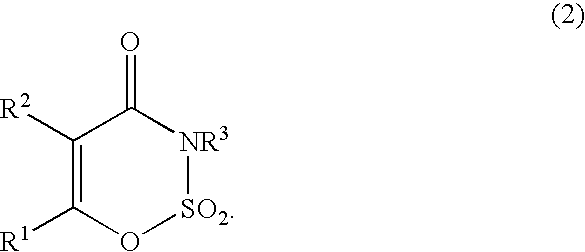

A high quality 3,4-dihydro-1,2,3-oxathiazin-4-one-2,2-dioxide compound or a salt thereof is obtained easily and efficiently.When the compound represented by the following formula (2)(wherein, R1, R2, and R3 are hydrogen atom or an organic group inert to the reaction, and X is hydrogen atom) or a salt thereof is produced by cyclization of a mixture of β-ketoamide-N-sulfonic acid represented by the following formula (1)or a salt thereof and an inert solvent and a mixture of acid anhydride and an inert solvent, and by subsequent hydrolysis of the product, a step of (A) hydrolyzing the reaction product obtained by the cyclization by mixing with an aqueous solution of sulfuric acid so as a concentration of sulfuric acid in an aqueous phase after the hydrolysis would become 30% by weight or more, and then separating an organic phase and an aqueous phase, or a step of (B) washing the organic phase liquid after the hydrolysis with an aqueous solution of sulfuric acid with a concentration of 30% by weight or more is at least carried out.

Owner:DAICEL CHEM IND LTD

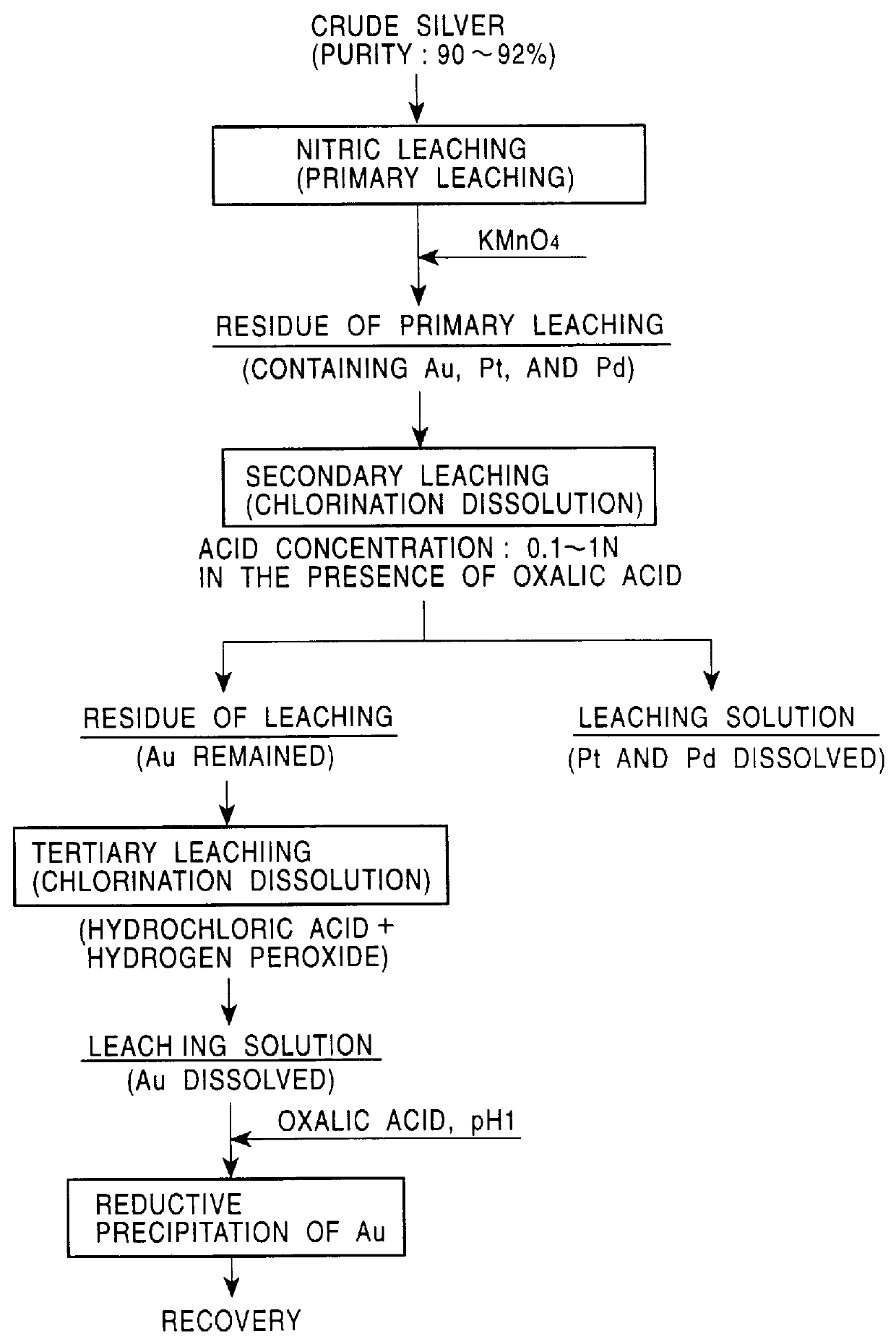

Method for smelting noble metal

InactiveUS6126720AShorten the timeReduce impurityPhotography auxillary processesSolvent extractionDecompositionMaterials science

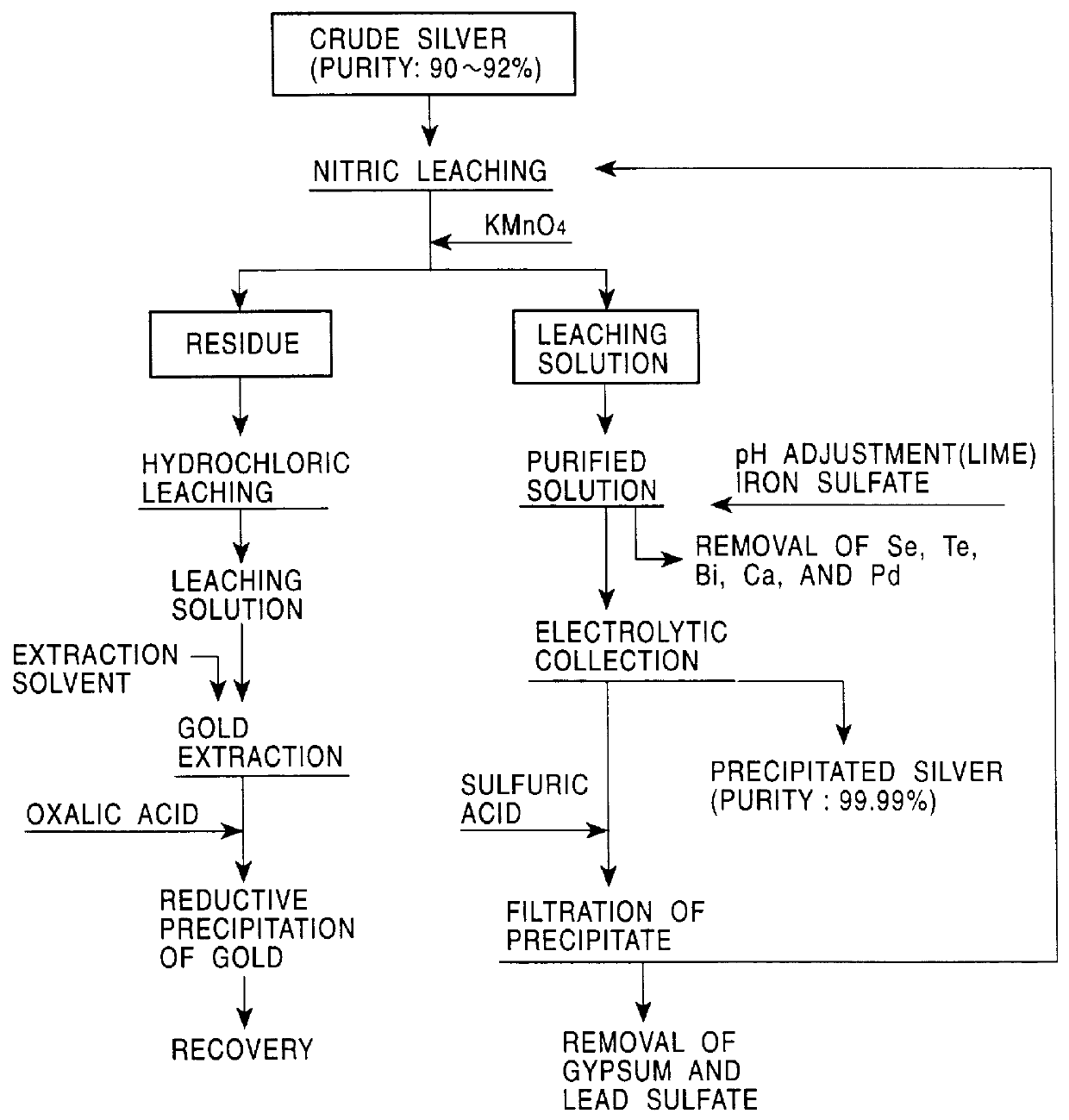

PCT No. PCT / JP98 / 02479 Sec. 371 Date Jan. 15, 1999 Sec. 102(e) Date Jan. 15, 1999 PCT Filed Jun. 4, 1998 PCT Pub. No. WO98 / 58089 PCT Pub. Date Dec. 23, 1998A method for refining noble metals has a silver treating process including a nitric acid leaching step of silver, a purification step of the leaching solution, an electrolytic decomposition step of silver, and a recycling step after the electrolytic decomposition, wherein in the purification step, lime is added in order to precipitate the metallic impurities, such as selenium, tellurium, bismuth, and copper, by neutralization of the leaching solution, and in the recycling step, sulfuric acid is added to the solution after electrolytic decomposition to regenerate nitric acid for recycling use by precipitation of calcium in the solution as gypsum. Preferably, the refining method has a gold recovery process, as well as the silver treating process, wherein the residue of the nitric leaching of the crude silver is dissolved by chlorination and gold is recovered from the leaching solution by solvent extraction or reductive precipitation. High purity gold and silver can be readily obtained, and the refining time for gold is significantly shorter than that in conventional methods.

Owner:MITSUBISHI MATERIALS CORP

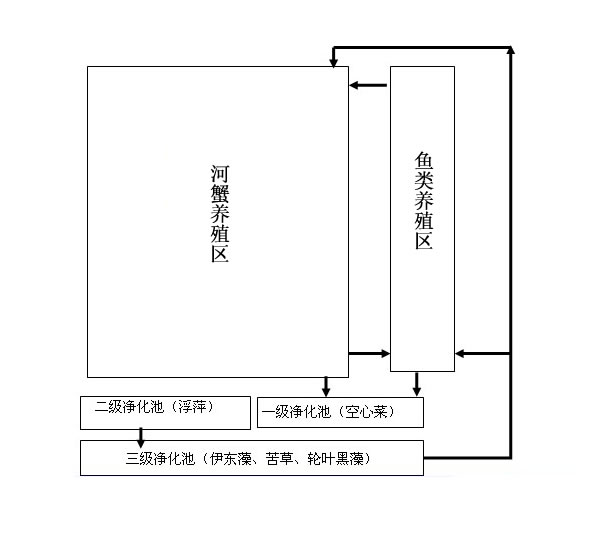

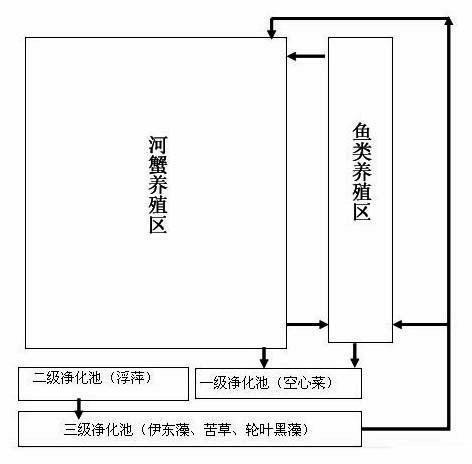

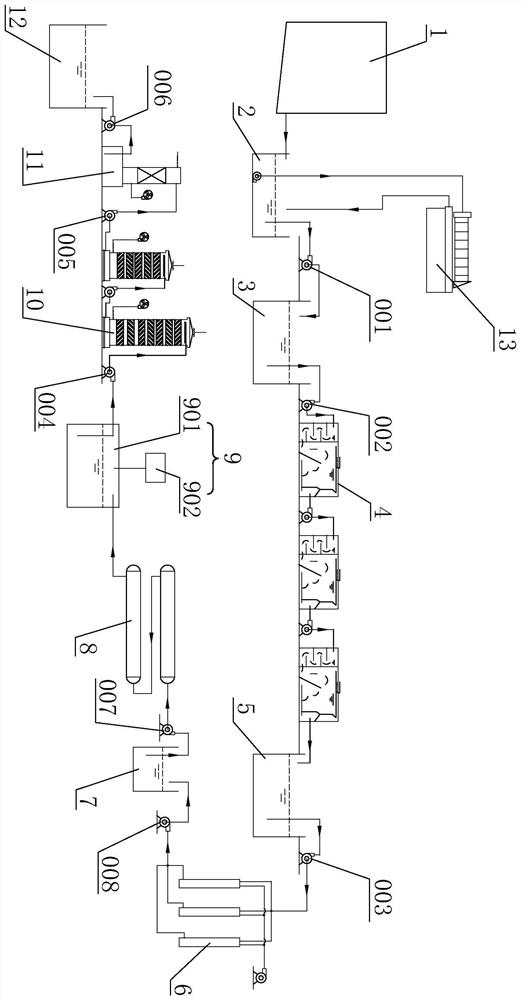

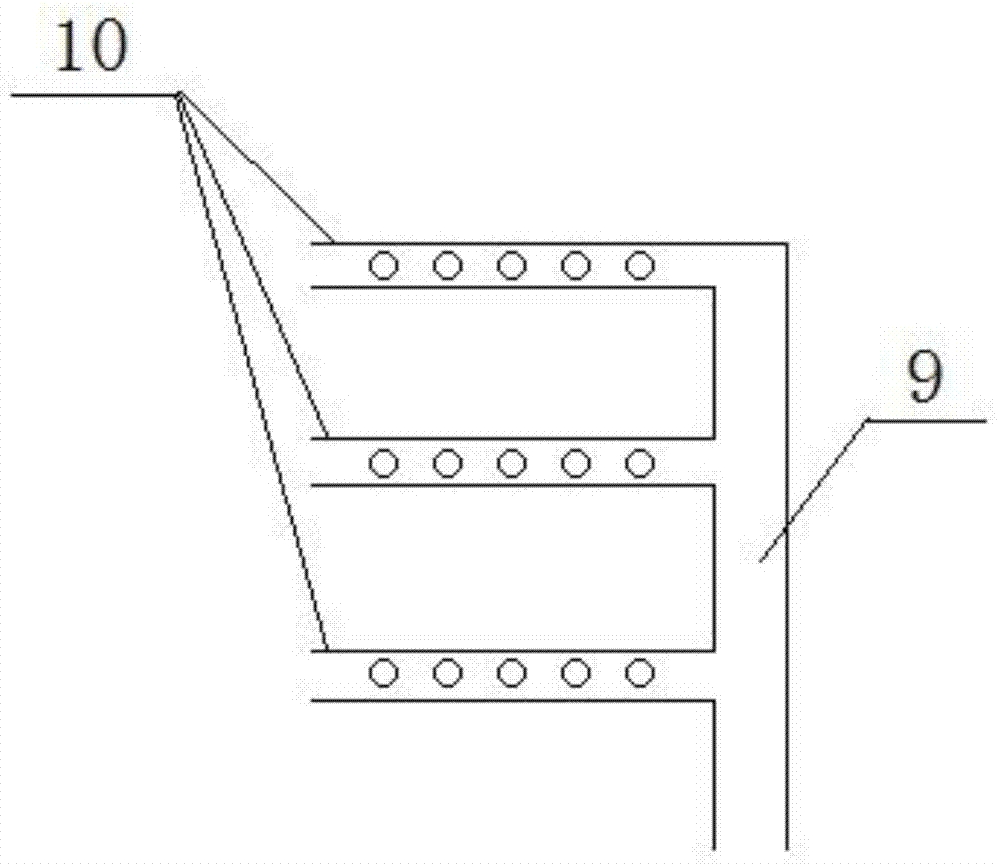

Distribution of environment-friendly aquaculture farm

InactiveCN102630626ARealize resource utilizationAvoid secondary pollutionPisciculture and aquariaNutrientAquaculture

The invention belongs to the field of aquaculture, and particularly relates to distribution of an environment-friendly aquaculture farm, which includes a fish culture area, a river crab culture area and a tail water purification area from the upstream to the downstream. Tail water from the fish culture area is drained to the river crab culture area, the tail water from the river crab culture area is drained to the tail water purification area, and water from an outlet of the tail water purification area is then diverted into the fish culture area. The water in the river crab culture area can also be diverted into the fish culture area directly, and the water in the fish culture area can also be diverted into a primary purification tank in the tail water purification area directly. By using the distribution, the area of the tail water purification area can be reduced, the quality of river crabs can be improved, and recycling of culture tail water and nutrient pollutant can be achieved.

Owner:SUZHOU YANGCHENG LAKE XIAOJING SHRIMP & CRAB PRODN & SALES PROFESSIONAL COOP +2

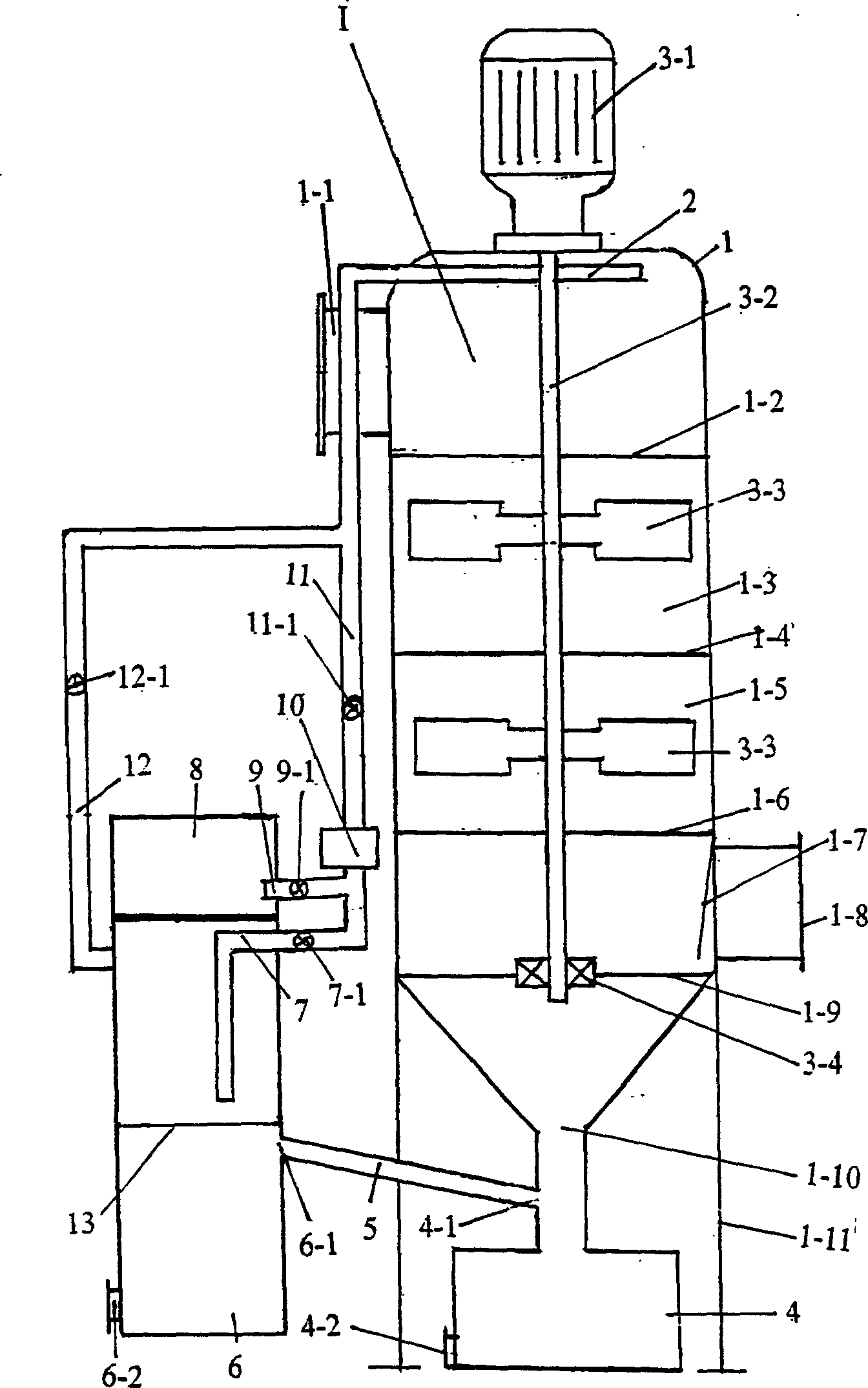

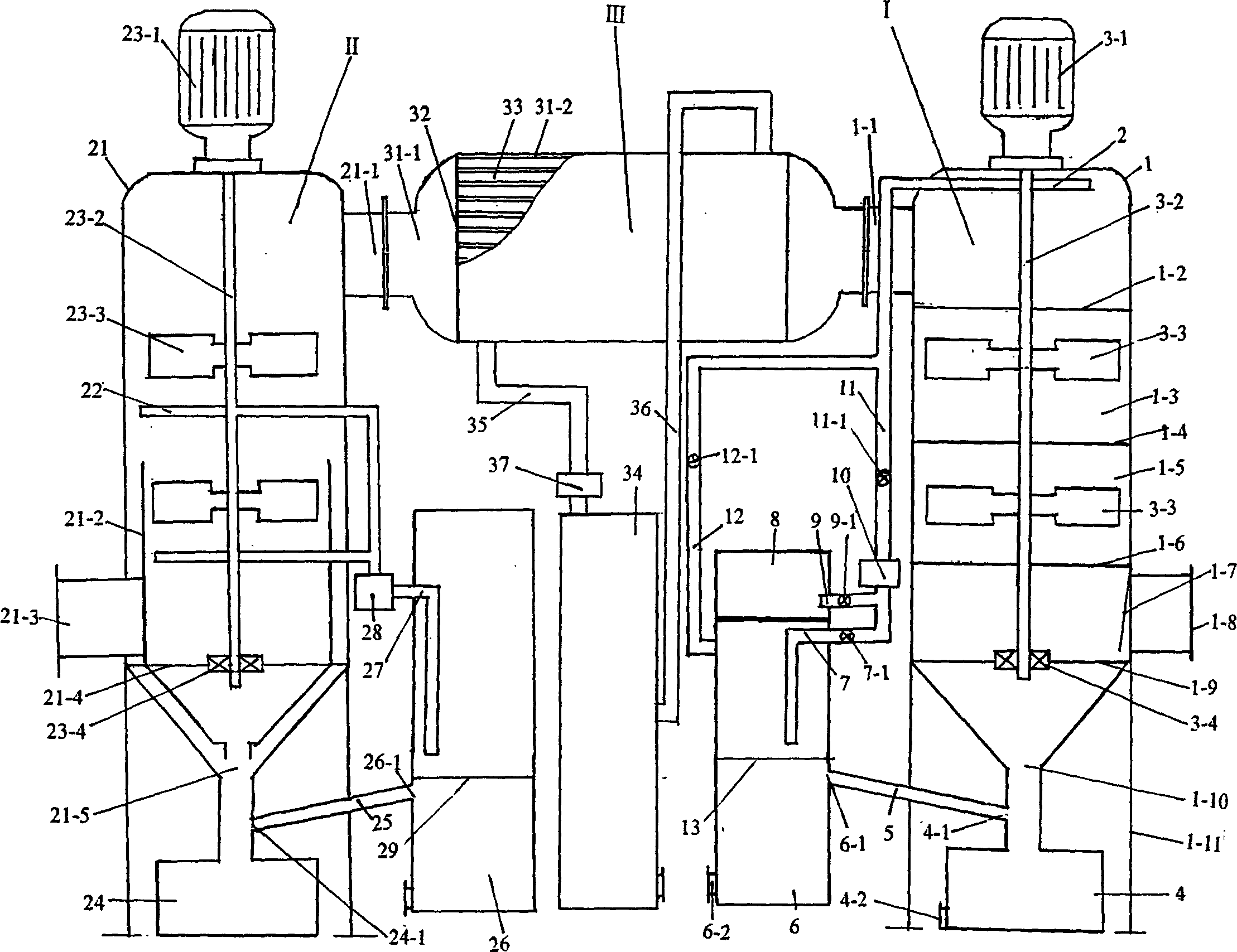

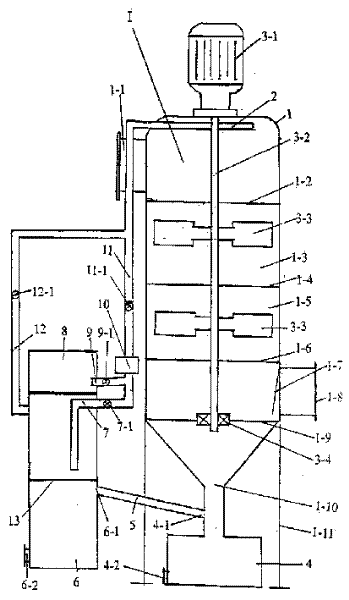

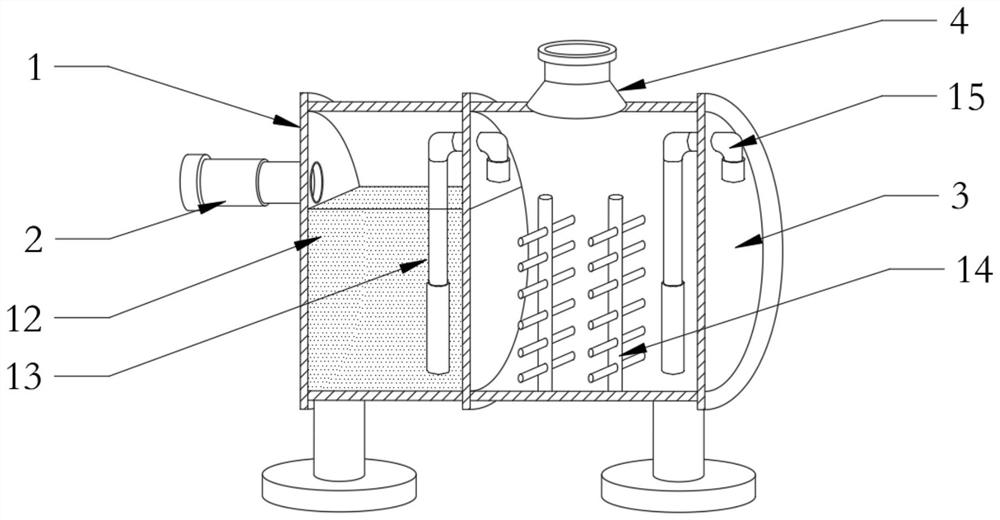

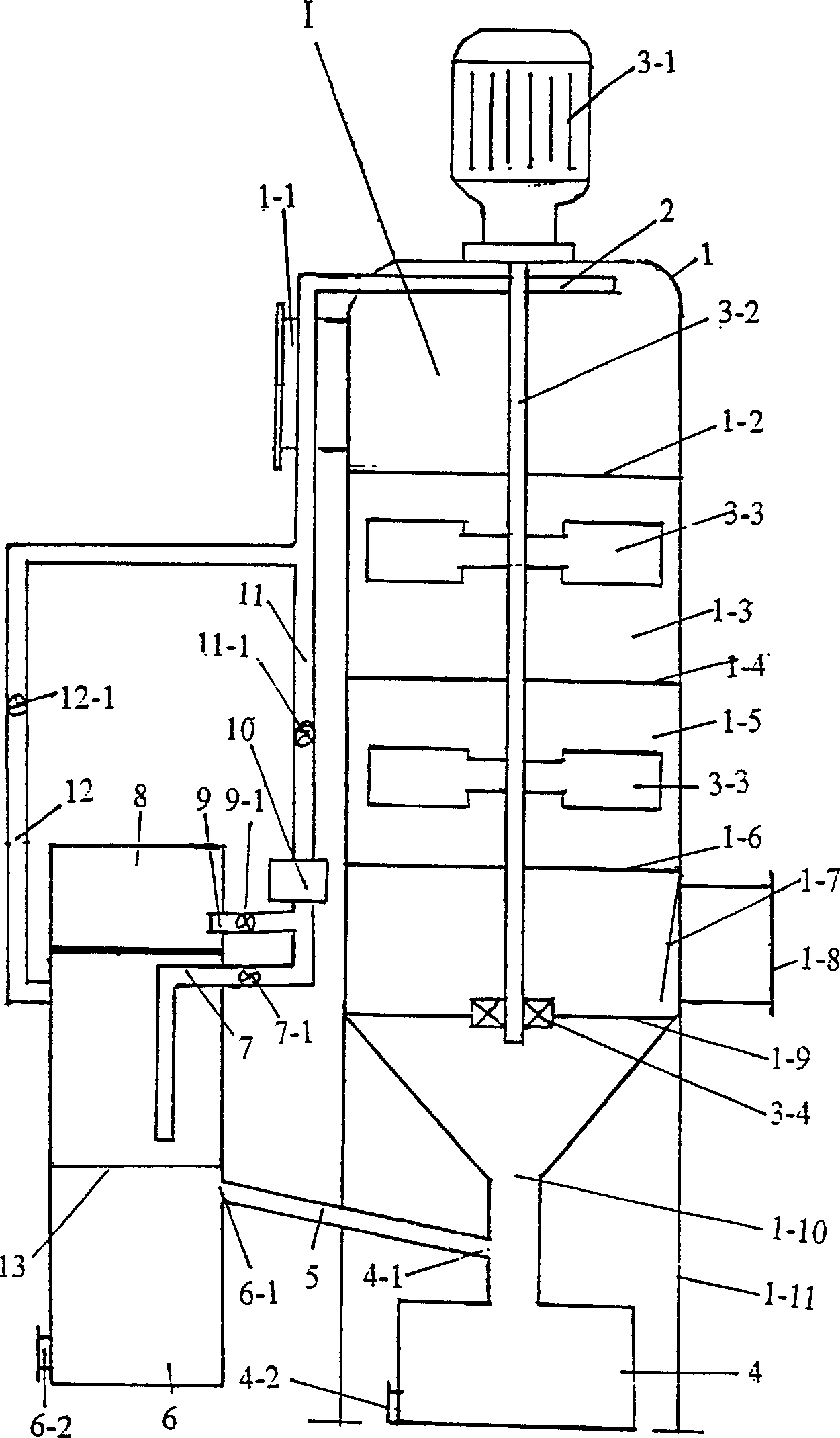

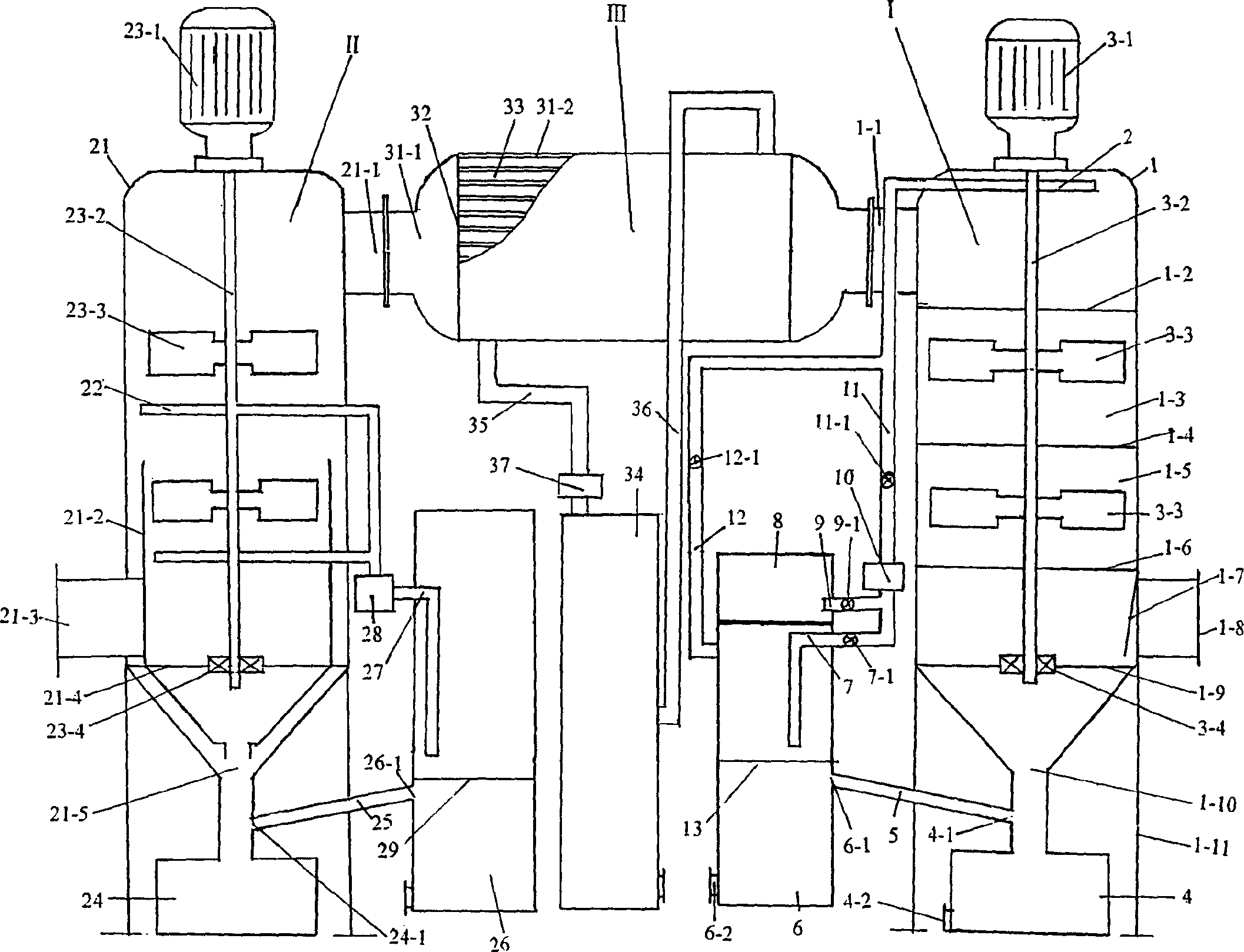

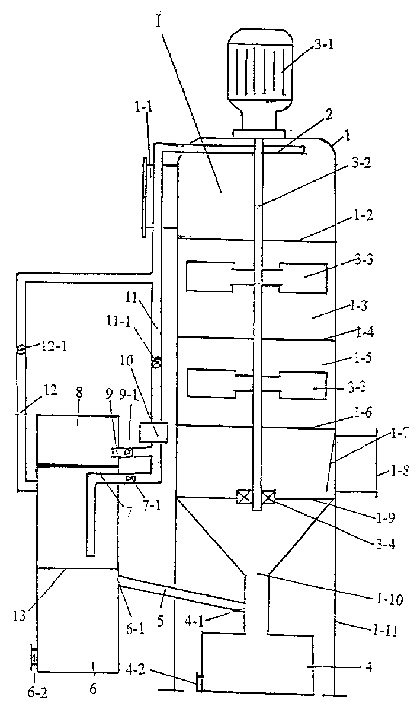

Wet type dual-collecting and fume purifying apparatus

InactiveCN1470311AEfficient removalReduce purification loadUsing liquid separation agentSprayerEngineering

The invention is a kind of dust catching and smoke clarifying device which uses clarifier to form foam layer. It has foam clarifier, there's sprayer, upper and nether net board in the barrel. The foam room is between the two boards. The smoke inlet and outlet of foam clarifier are set on the upper and nether part. The dust outlet is set on the bottom of the barrel and connects with dust gatheringbox. There's an axis in the barrel which connects with the axis of the electromotor. The axis in the foam room connects some vanes; there's circular water box and clarifier box by the side of the barrel.

Owner:杨长明

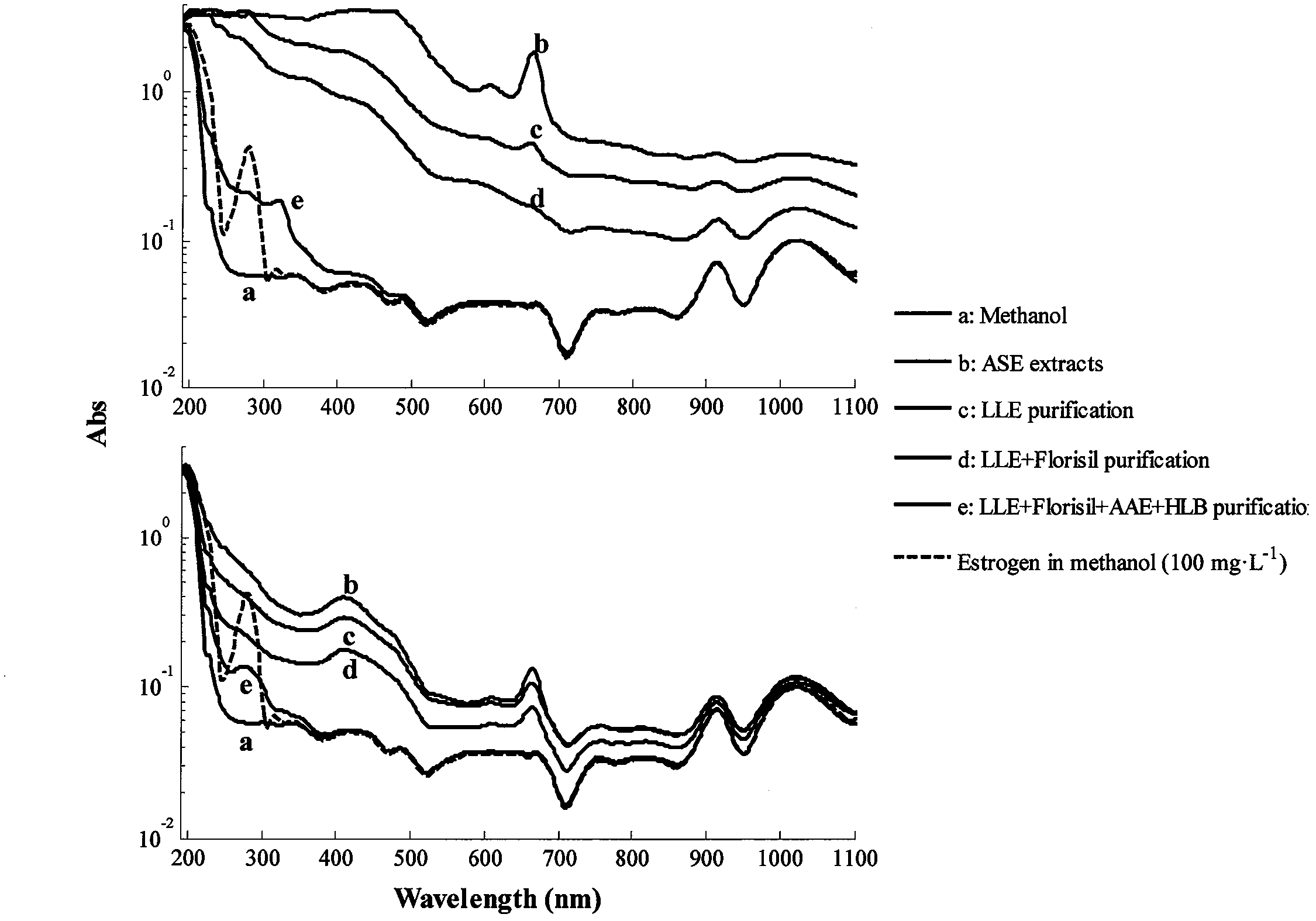

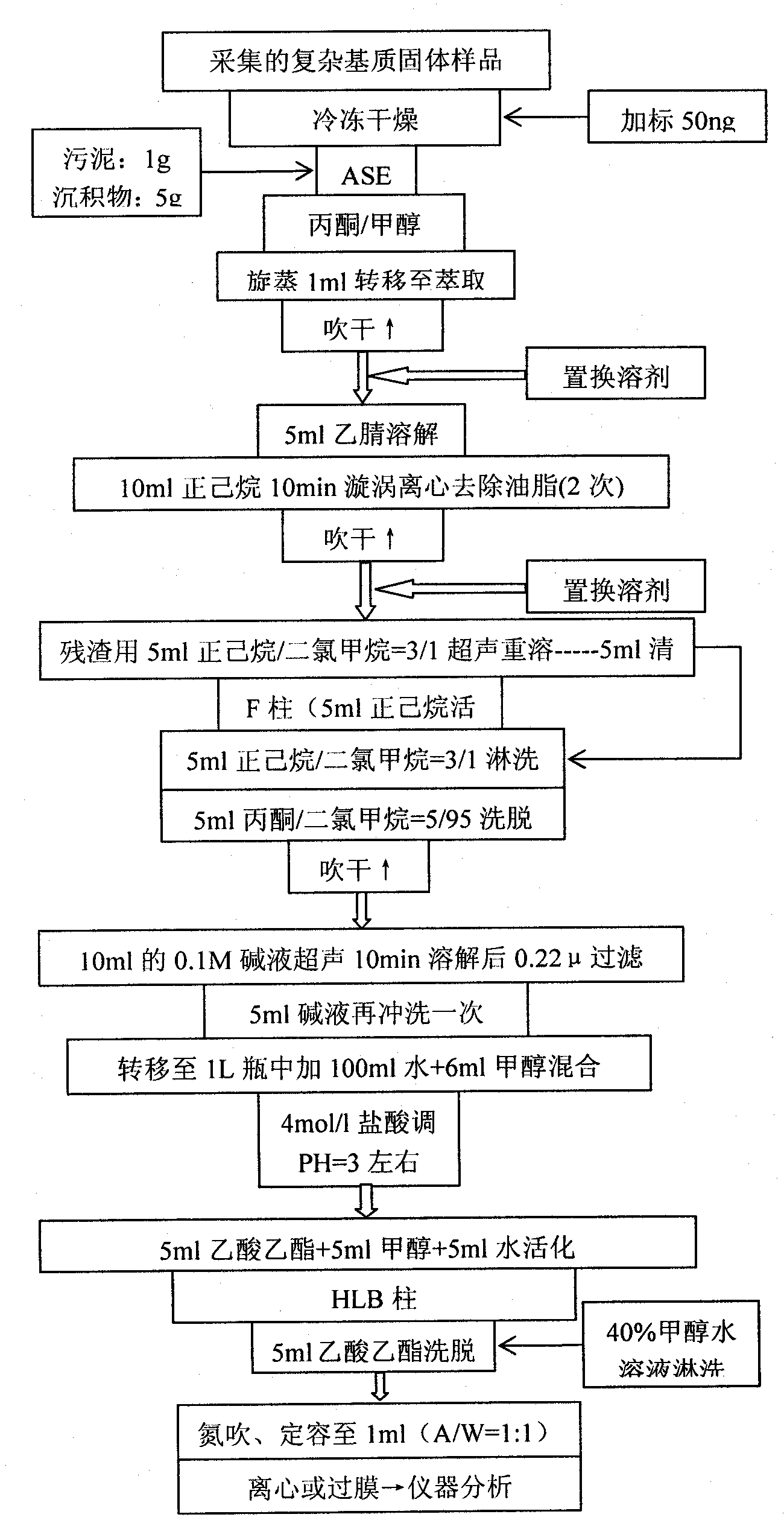

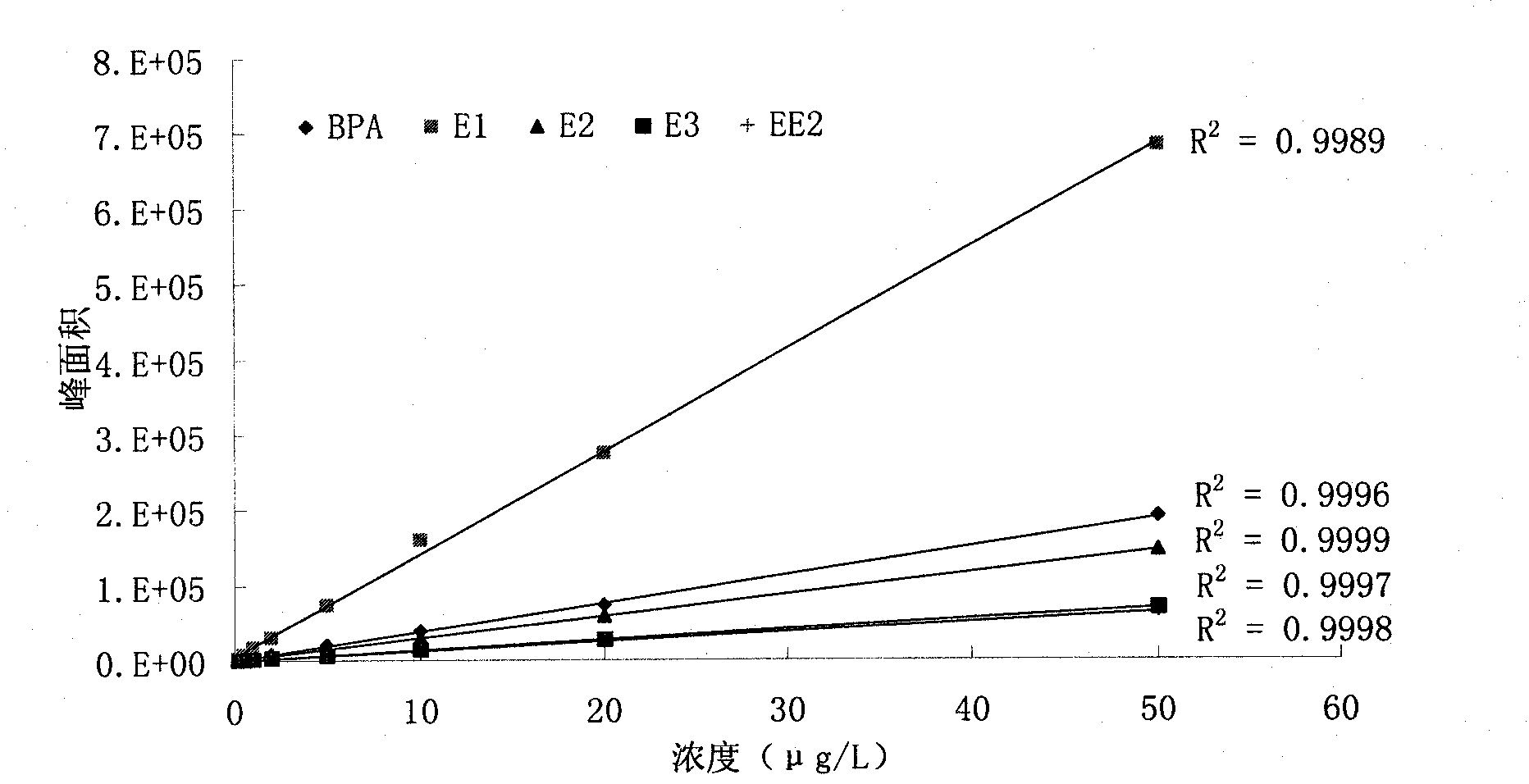

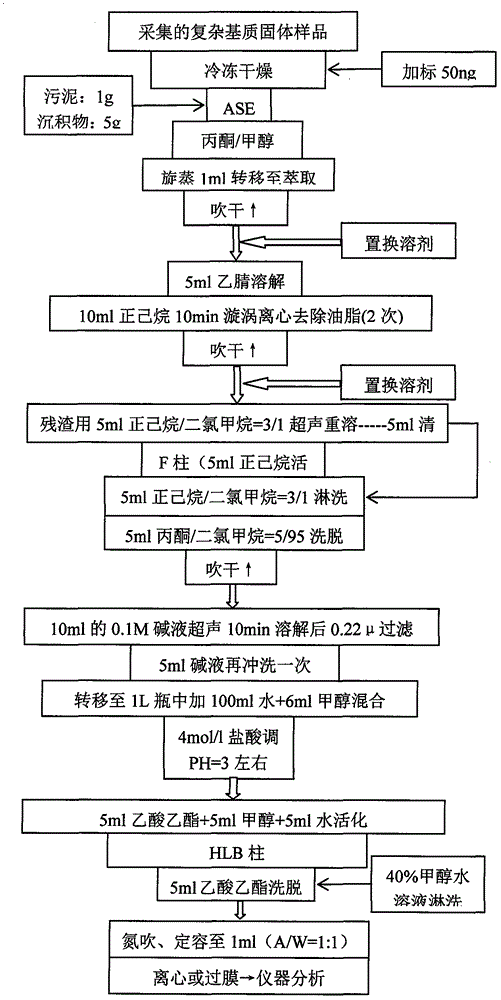

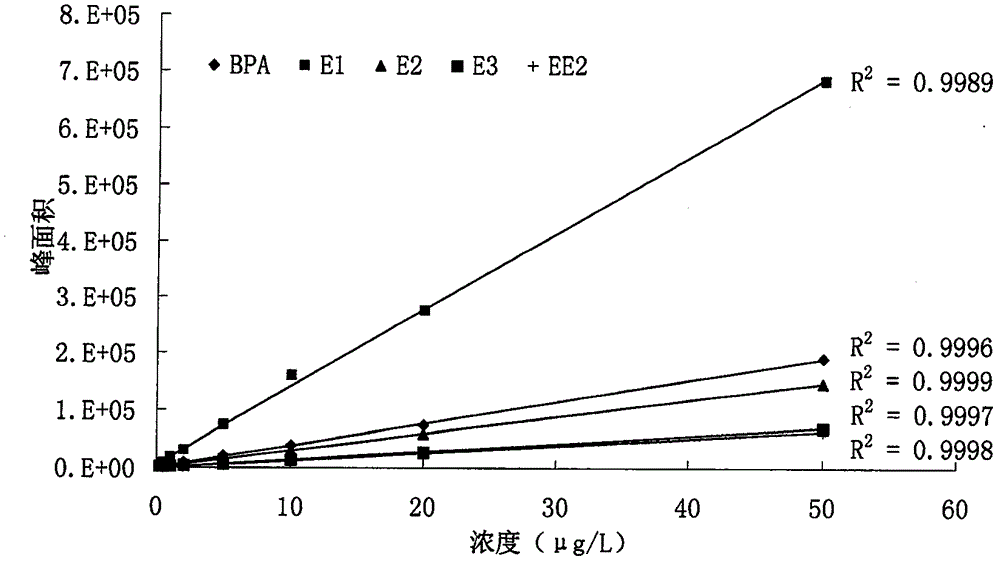

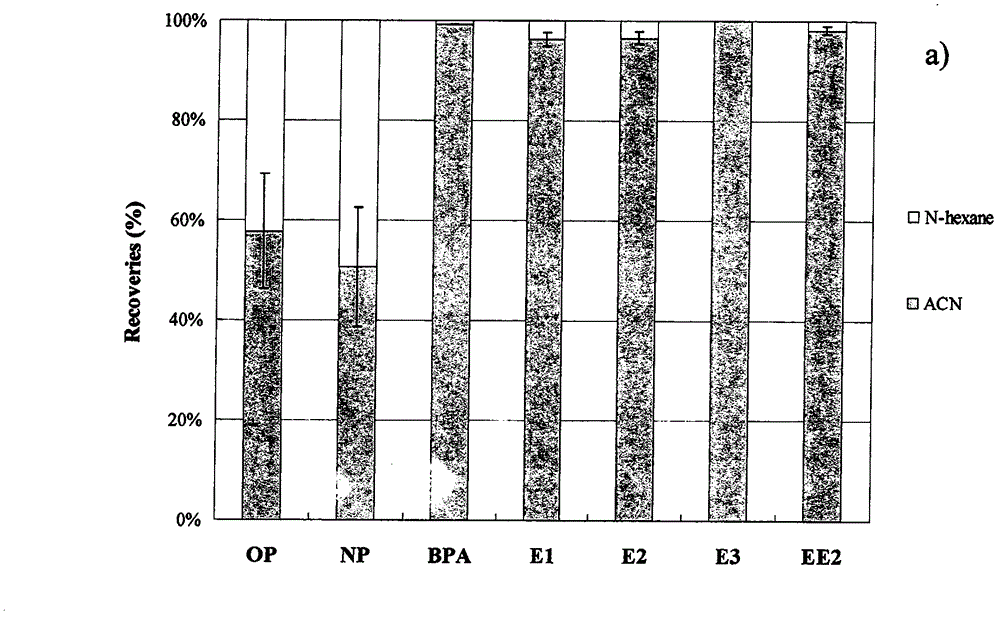

Preprocessing method suitable for analyzing estrogen and bisphenol A in complex matrix solid sample

InactiveCN102435681AReduce purification loadImprove purification effectComponent separationLiquid chromatography mass spectroscopySludge

The invention discloses a preprocessing method suitable for analyzing estrogen and bisphenol A in a complex matrix solid sample, which is a method for detecting the estrogen and the bisphenol A based on accelerated solvent extraction-liquid-liquid extraction-Florisil column purification-alkaline solution extraction-HLB (Hydrophile Lipophile Balance) column enrichment purification-liquid chromatogram / tandem mass spectrometry (ASE-LLE-Florisil-AS-HLB-LC / MS / MS). The method comprises the following steps of: taking acetone and methanol in a volume ratio of 1 : 1 (v / v) as extracting agents for the accelerated solvent extraction of the estrogen and the bisphenol A in sludge and deposit; taking acetonitrile-normal hexane system for the liquid-liquid extraction to remove non-polar impurities such as grease and polycyclic aromatic hydrocarbon and the like; taking the Florisil column for purifying most of pigments; extracting the estrogen and the bisphenol A from residue by using 0.1mol / L of sodium hydroxide; filtering by a filter membrane of 0.22 um[m]; and enriching and purifying by using an HLB column. According to the method, the recovery rate of the estrogen and the bisphenol A is 75-100%, the detection limit is lower than 0.4ng / g, the purification effect is good and the detection requirement for the estrogen in the complex matrix solid sample is satisfied. According to the research result, the estrogens and the bisphenol A in the sludge, the deposit and the livestock and poultry manure sample can be quickly and effectively separated and purified, the accuracy and stability of the method can be favorably improved and the damage of the complex sample on the instrument also can be reduced.

Owner:BEIJING NORMAL UNIVERSITY

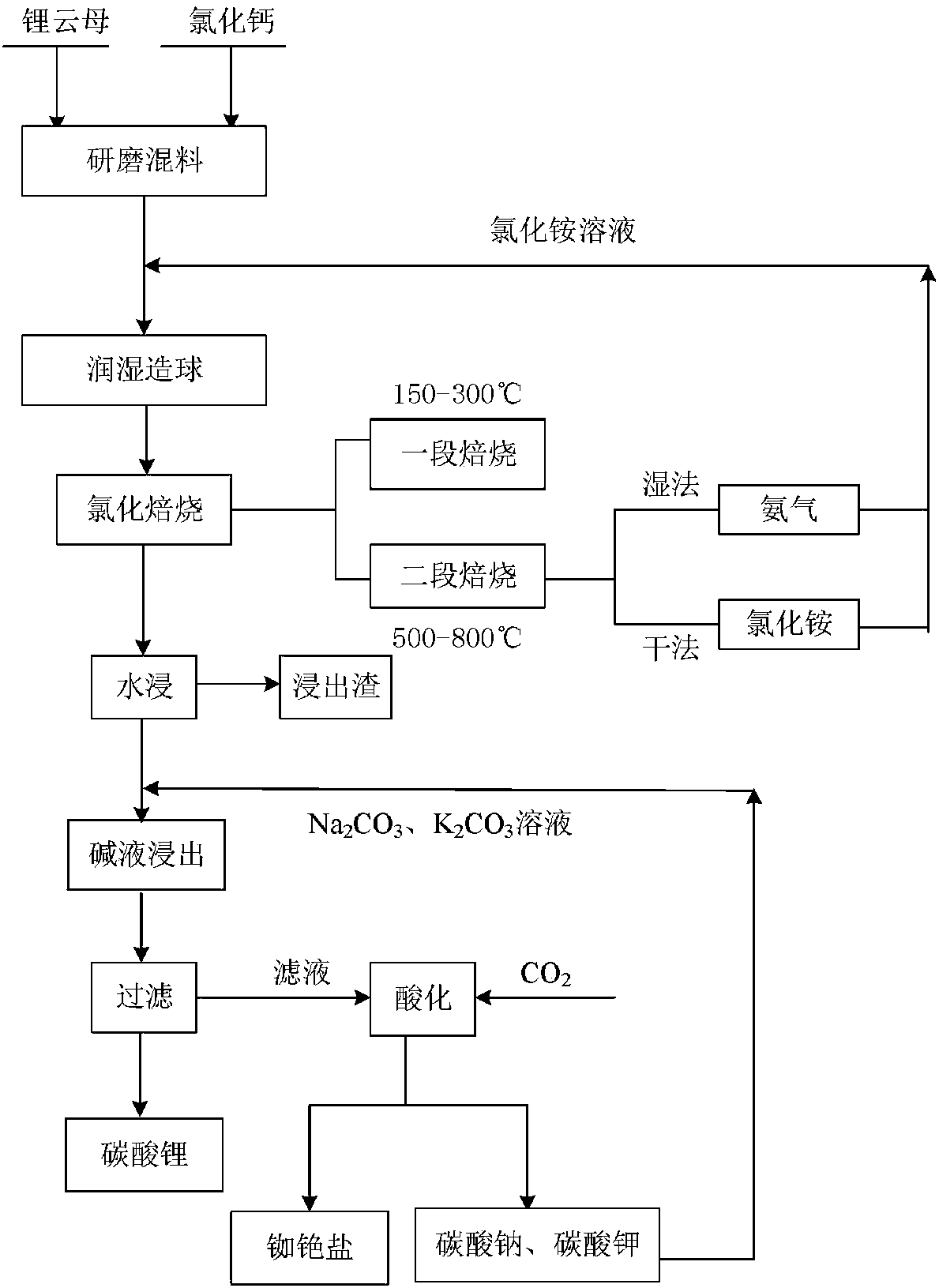

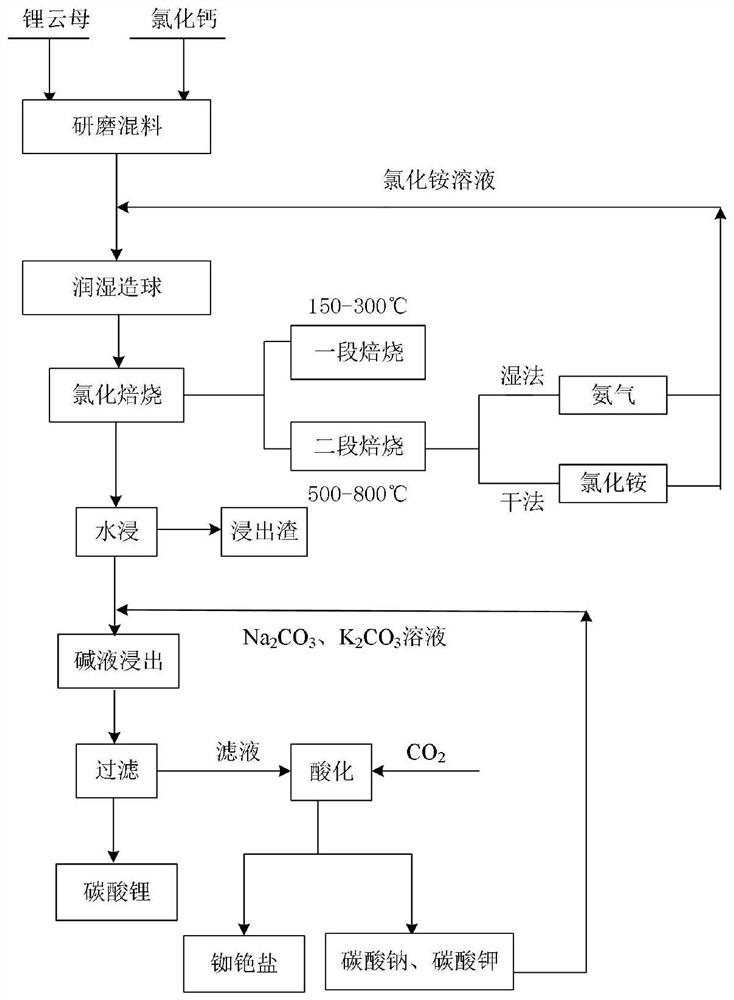

Method for preparing lithium carbonate by extracting lithium from lepidolite by adopting two-stage chloridizing roasting and alkali liquor leaching method

ActiveCN108118143ALow melting pointImprove reaction kineticsProcess efficiency improvementPregnant leach solutionLithium carbonate

The invention discloses a method for preparing lithium carbonate by extracting lithium from lepidolite by adopting two-stage chloridizing roasting and an alkali liquor leaching method. The method disclosed by the invention comprises the following steps: (1) levigating the lepidolite and calcium chloride, adding the levigated lepidolite and calcium chloride into ammonium chloride solution, uniformly blending and pelletizing, so as to obtain green balls; (2) performing first-stage roasting on the green balls obtained in step (1) at the temperature of 150-300 DEG C and performing second-stage roasting on the green balls at the temperature of 500-800 DEG C, so as to obtain clinkers; (3) leaching the clinkers obtained in step (2) with water, and filtering to obtain leaching solution; (4) addingcarbonate solution into the leaching solution obtained in step (3), stirring and filtering to obtain mother solution and filter residues, and collecting the filter residues, so as to obtain the lithium carbonate. In the method disclosed by the invention, all the steps are cooperated, and a process of preparing the lithium carbonate by extracting the lithium from the lepidolite is environmentallyfriendly, low in energy consumption, low in cost and high in extracting efficiency. Therefore, the method disclosed by the invention has a broad industrial application prospect.

Owner:CENT SOUTH UNIV

Method for producing 3,4-dihydro-1,2,3-oxathiazin-4-one-2,2-dioxide compound or salt thereof

A high quality 3,4-dihydro-1,2,3-oxathiazin-4-one-2,2-dioxide compound or a salt thereof is obtained easily and efficiently.When the compound represented by the following formula (2)[Formula 2](wherein, R1, R2, and R3 are hydrogen atom or an organic group inert to the reaction, and X is hydrogen atom) or a salt thereof is produced by cyclization of a mixture of β-ketoamide-N-sulfonic acid represented by the following formula (1)[Formula 1]or a salt thereof and an inert solvent and a mixture of acid anhydride and an inert solvent, and by subsequent hydrolysis of the product, a step of (A) hydrolyzing the reaction product obtained by the cyclization by mixing with an aqueous solution of sulfuric acid so as a concentration of sulfuric acid in an aqueous phase after the hydrolysis would become 30% by weight or more, and then separating an organic phase and an aqueous phase, or a step of (B) washing the organic phase liquid after the hydrolysis with an aqueous solution of sulfuric acid with a concentration of 30% by weight or more is at least carried out.

Owner:DAICEL CHEM IND LTD

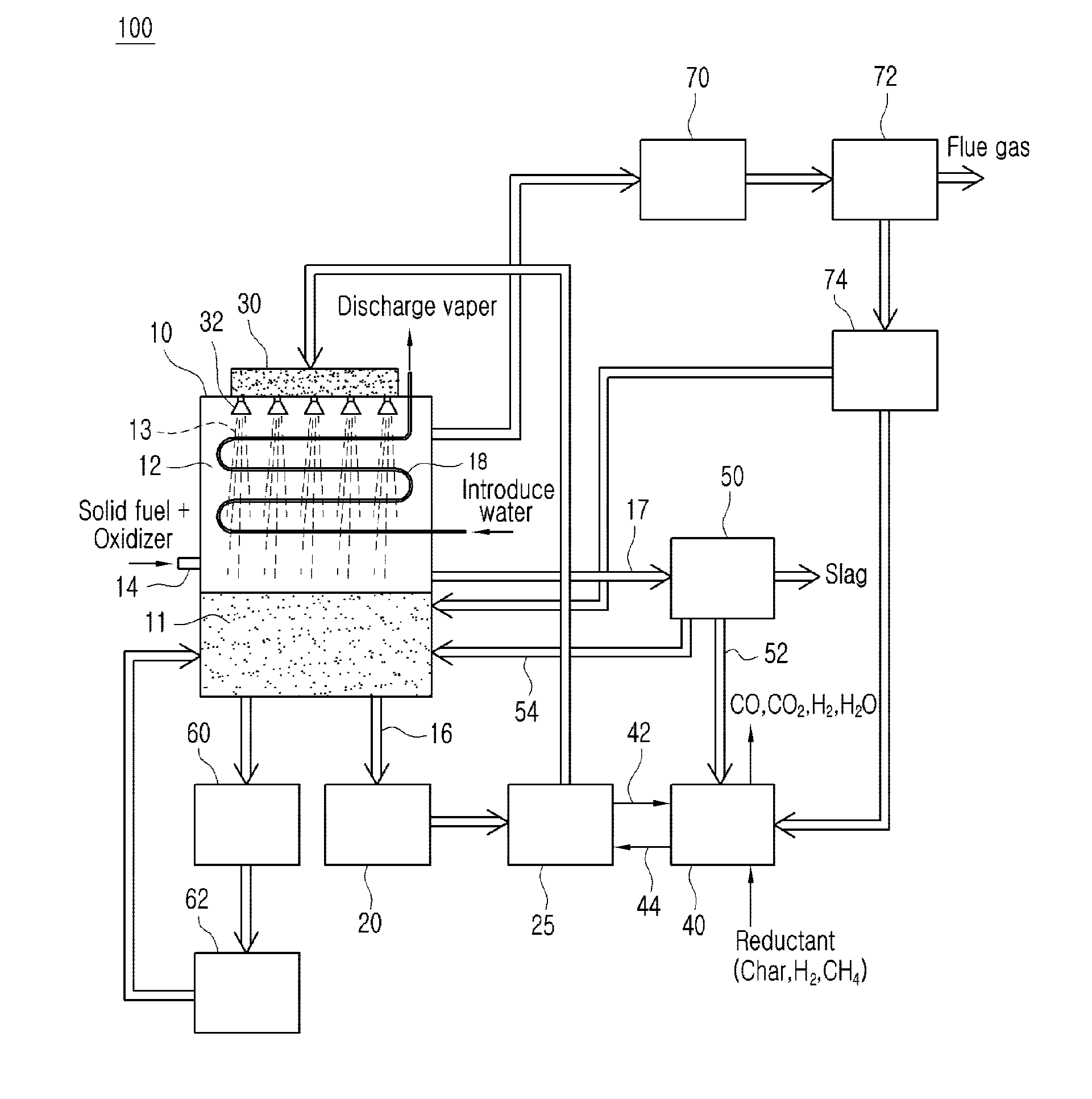

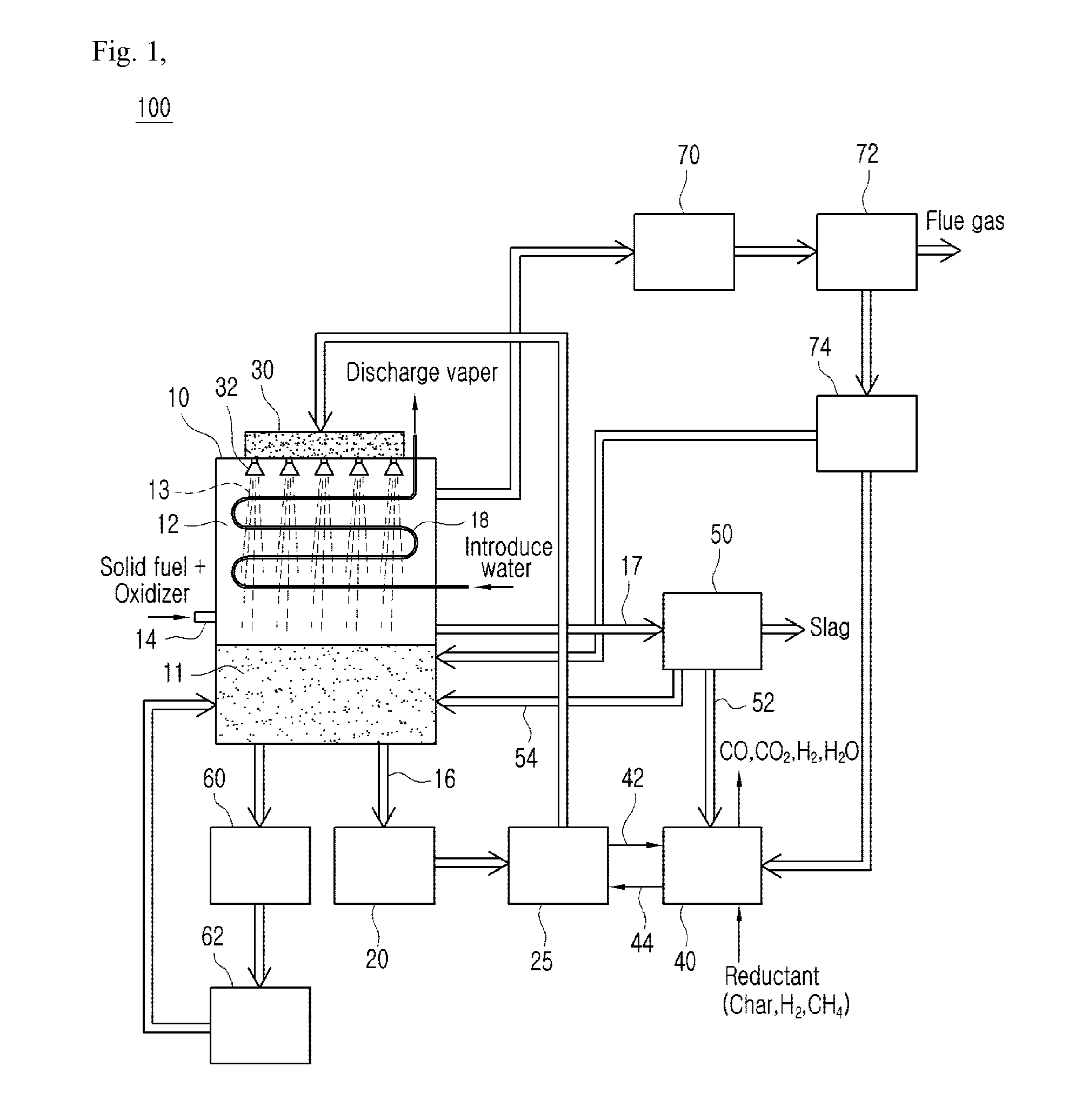

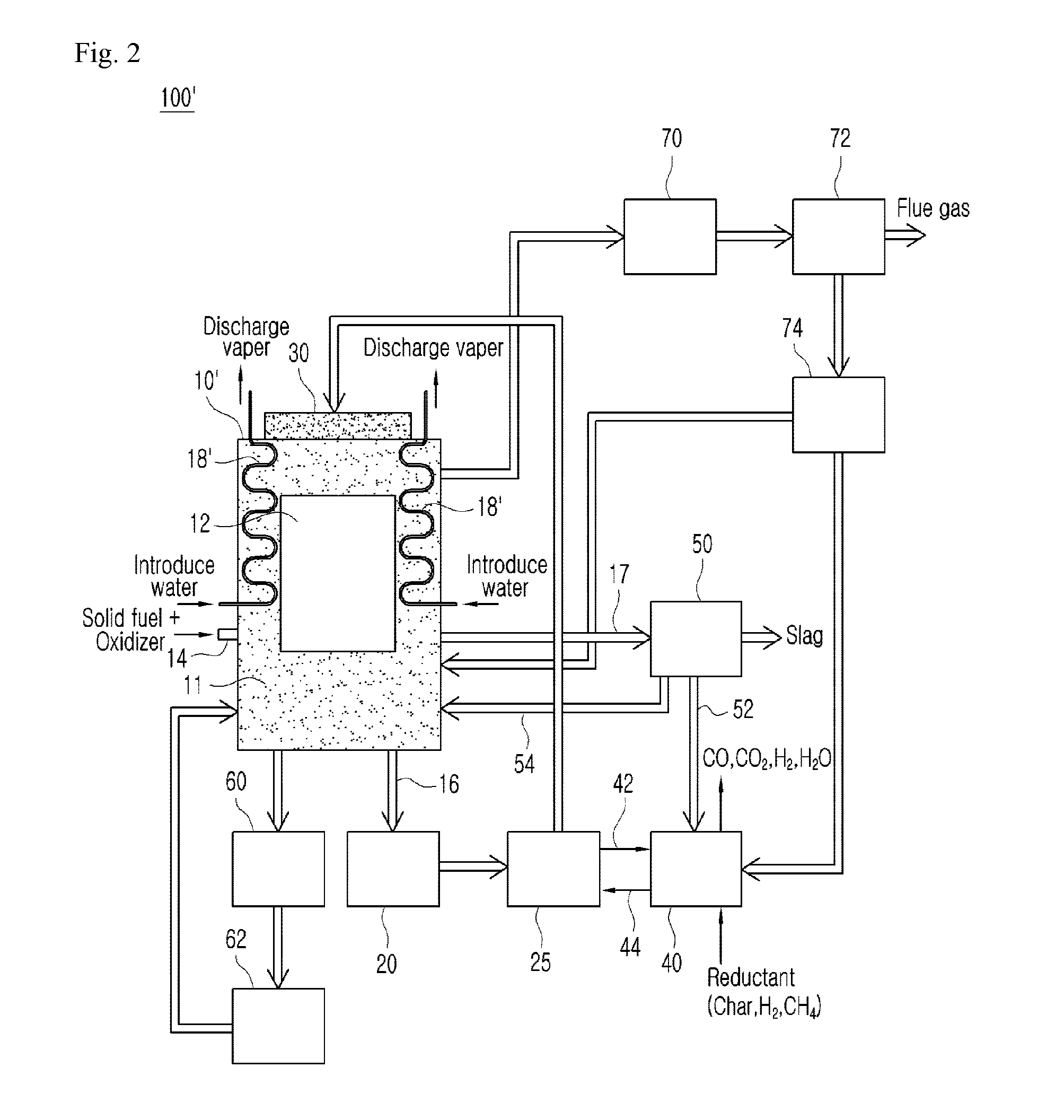

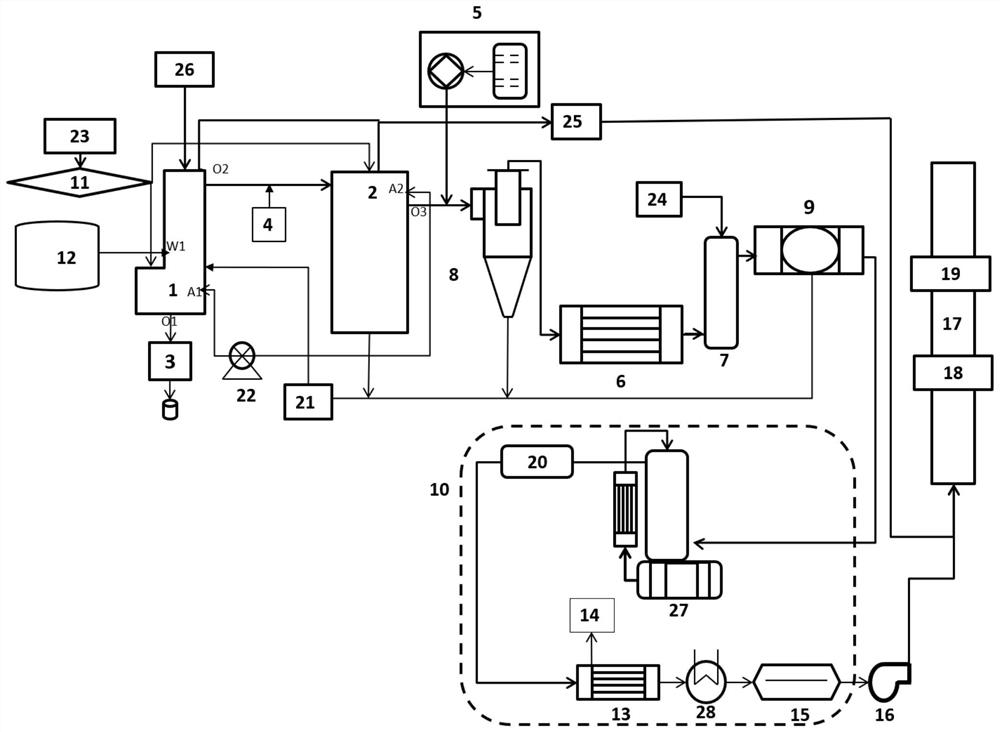

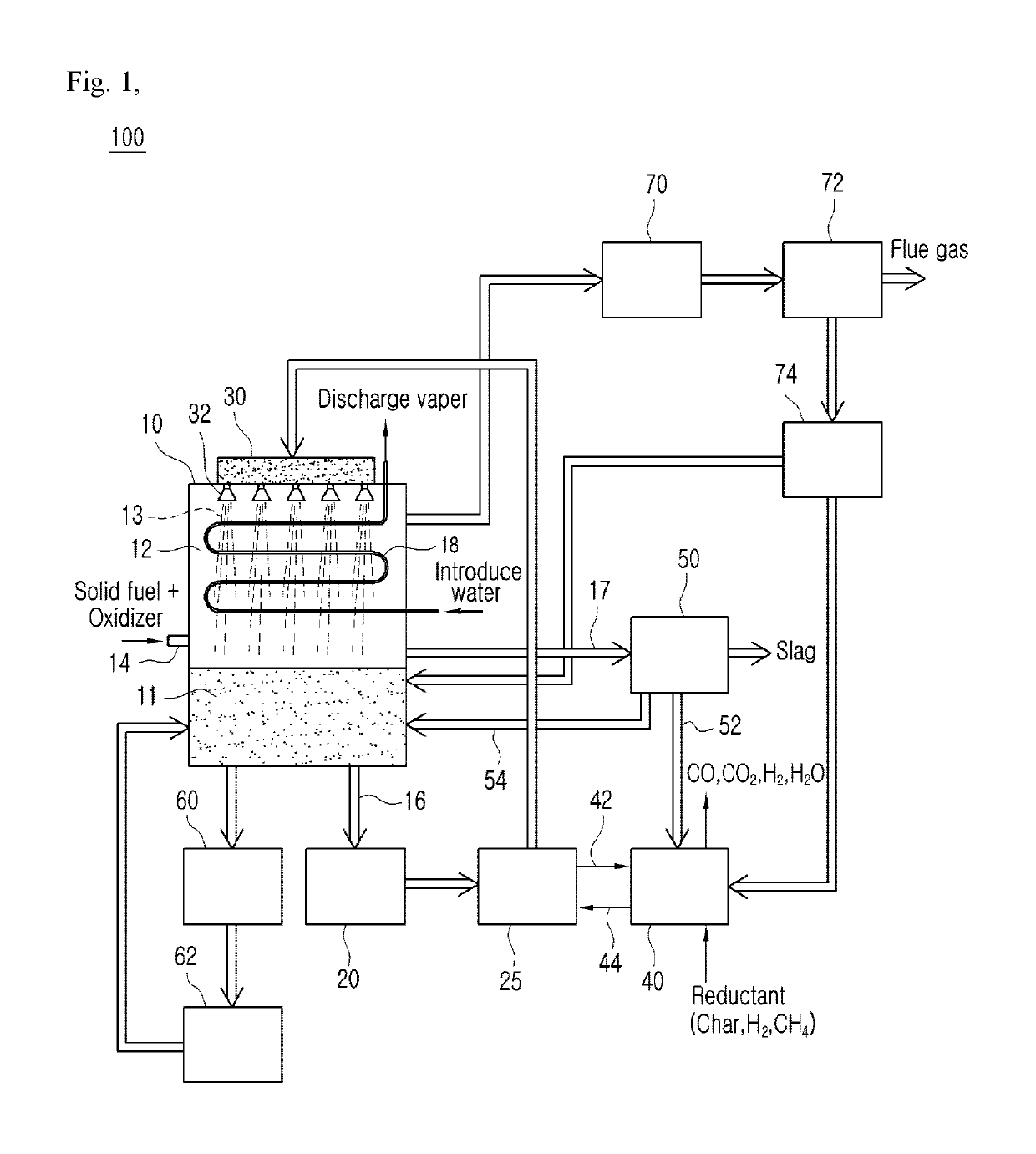

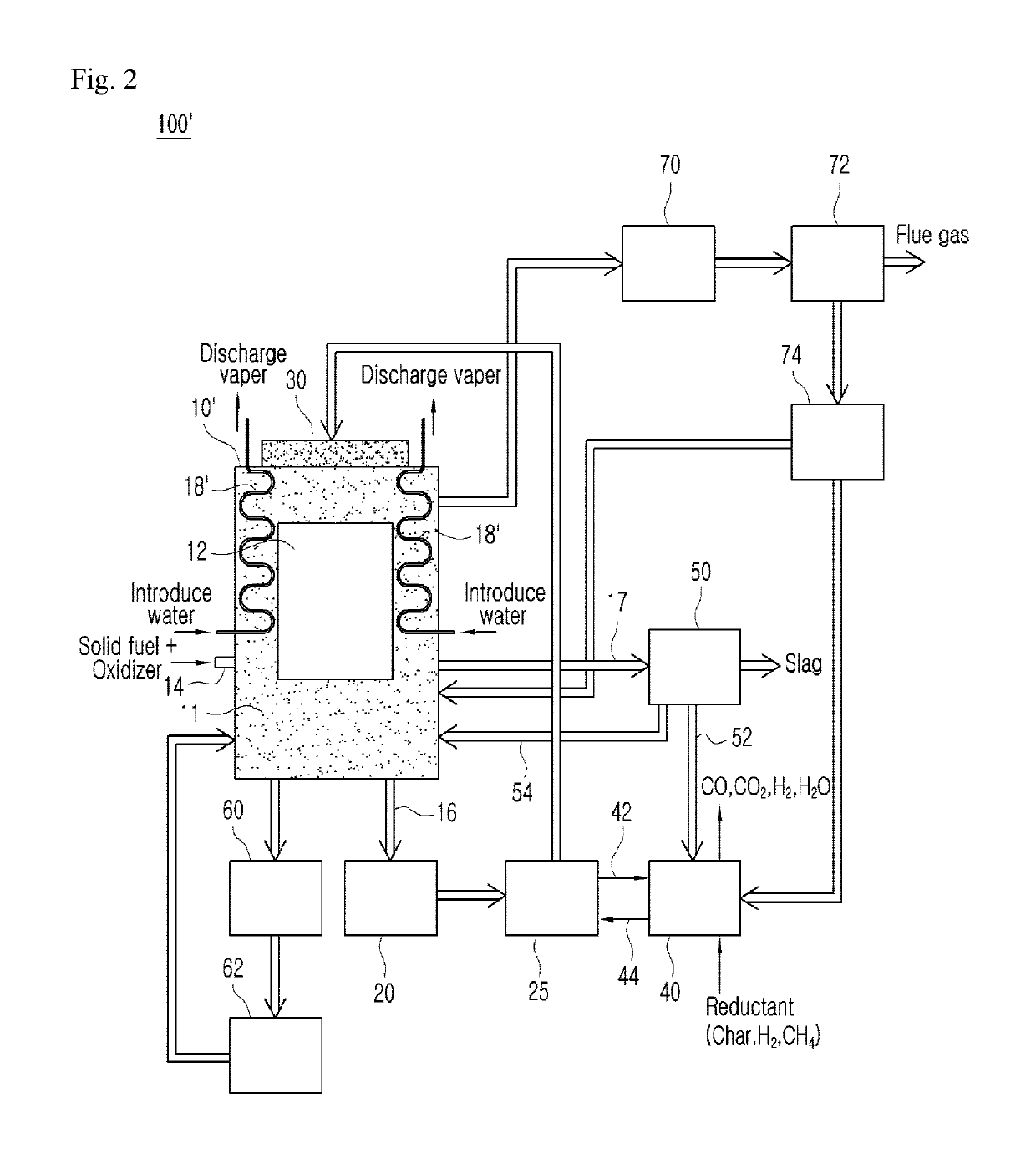

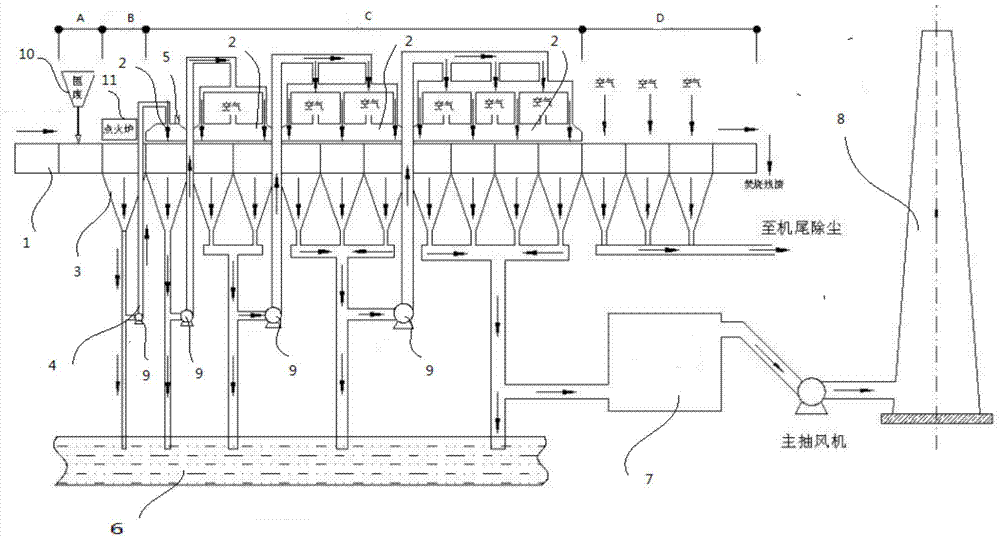

Pure oxygen direct combustion system using liquid metal

ActiveUS20170003022A1Reduce overloadReduce purification loadMaintainance of heating chambersCharge manipulationCombustion systemNuclear engineering

A pure oxygen direct combustion system using a liquid metal according to the present invention comprises: a reactor for receiving a liquid metal; a heat exchanger, connected to the bottom of the reactor, for exchanging heat for the liquid metal; a circulation pump, connected to the heat exchanger, for circulating the incoming liquid metal; a nozzle, connected to the circulation pump and disposed on the reactor; a reduction unit, connected to the circulation pump, for performing a reduction for the oxidized liquid metal; and a separation unit, connected to the reactor and the reduction unit, wherein the particles of the liquid metal injected from the nozzle are subjected to sensible heat from the gas generated from the reactor, heat-exchanged by the heat exchanger and regenerated by the reduction unit, and then supplied back to the reactor.

Owner:KOREA INST OF IND TECH

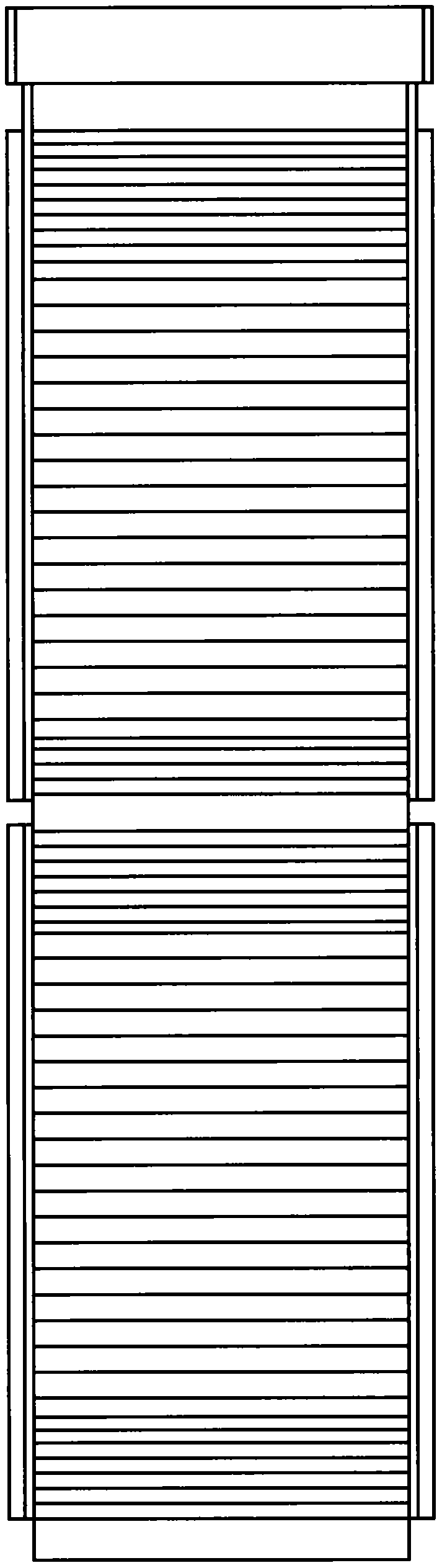

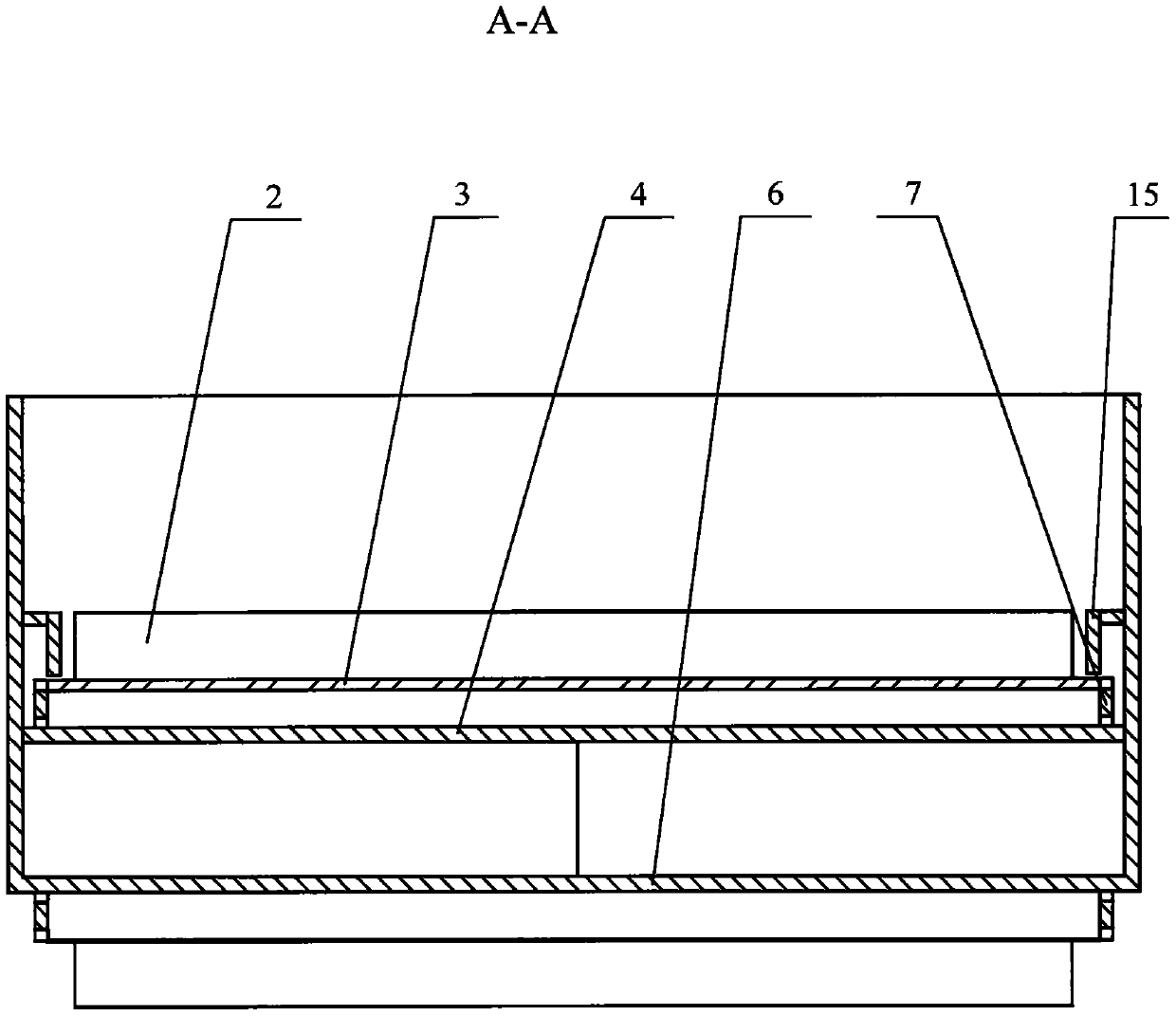

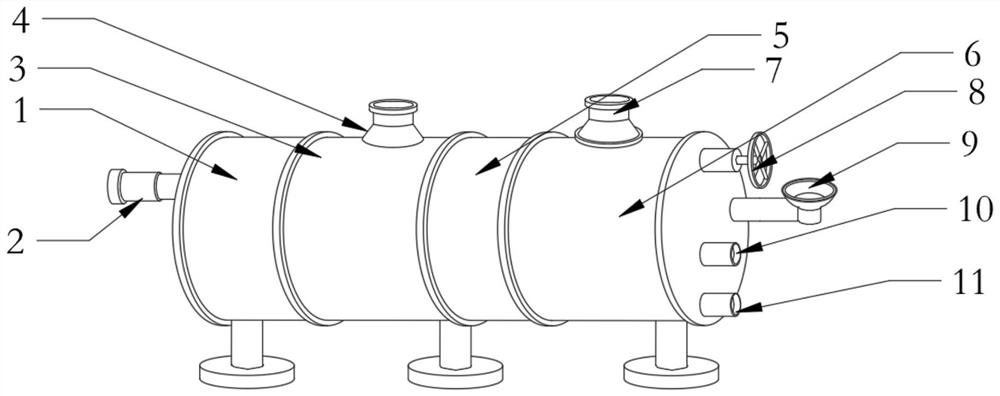

Method and device for continuously rinsing chemical activated carbon

The invention discloses a method and device for continuously rinsing chemical activated carbon. The rinsing device is a combination of a conveying chain plate, a long-strip-shaped rinsing water tank and an activated tail gas heating facility and comprises a feeding pipe, material partition plates, the conveying chain plate, a rinsing water tank bottom plate, an activated tail gas flow guide partition plate, an activated tail gas jacket, a chain wheel, an activated tail gas inlet, an activated tail gas connecting pipe, an activated tail gas outlet, a device supporting column, a spraying nozzle,an activated tail gas condensate discharge port, a rinsed carbon guide groove and side face material baffles. The rinsing water tank has the length of 10-15 m and the width of 0.6-1 m. The activatedtail gas jacket is arranged at the bottom of the water tank. The annular conveying chain plate is arranged on the inner side and the two ends of the water tank and the outer side of the activated tailgas jacket. The material partition plates perpendicularly welded to the chain plate at the interval of 0.4-0.6 m are arranged on the chain plate. The side face material baffles parallel to the side faces are arranged on the upper sides, on the two sides of the interior of the water tank, of the chain plate. A driving motor drives the chain wheel and the chain plate through a reduction gear to circularly run around the water tank in the upward, downward, leftward and rightward directions.

Owner:ZHEJIANG FORESTRY ACAD

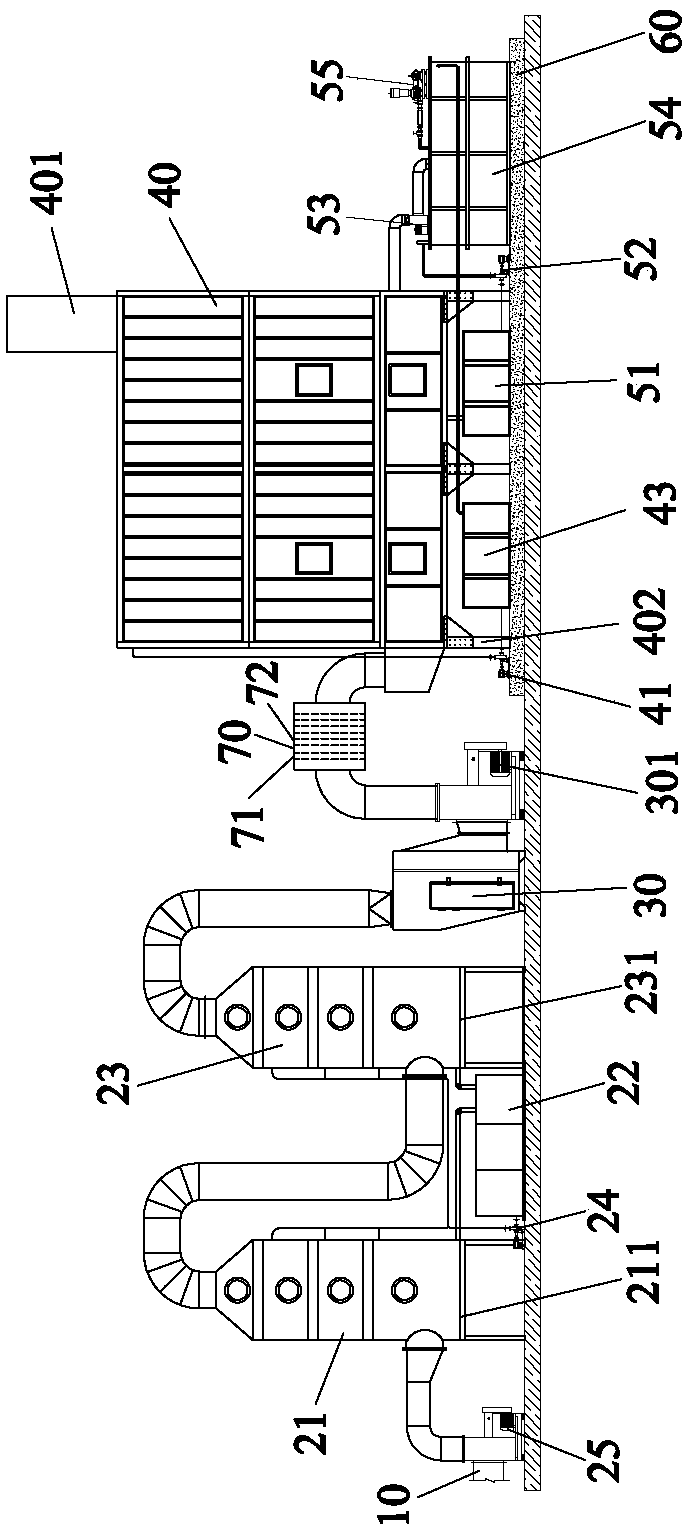

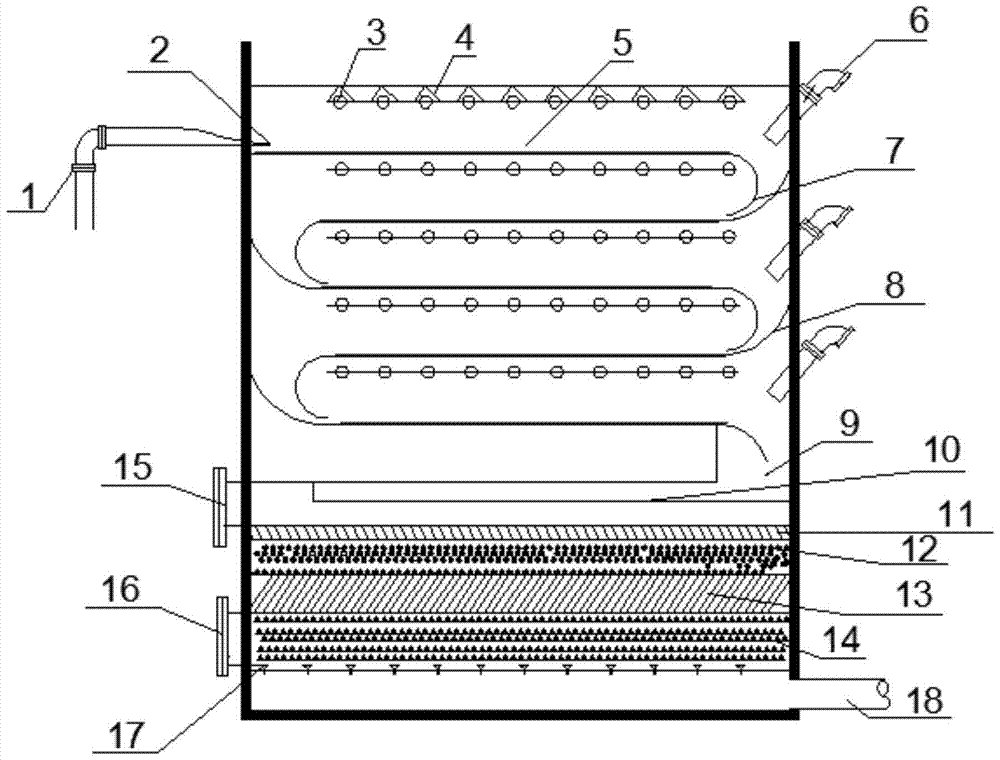

Organic waste gas biological purification system and method

InactiveCN109173701AImprove purification effectIncrease profitCombination devicesAir quality improvementSlagSustainability

The invention relates to an organic waste gas biological purification system and method. The system comprises a gas inlet pipe, a dust treatment device, a drying filter, a microbial filler filter tower, a biological liquid spray pump, a first spray device, a biofilm pool transfer water tank and a biofilm tank culture unit. The dust treatment device comprises a cyclone spray purification tower, a slag separation tank, a filler spray purification tower and a circulating water pump. The biofilm tank culture unit comprises a filtrate collection tank, a filtrate lifting pump, a biological exhaust fan, an MBBR biofilm tank and an oxygen supply fan. The system can effectively purify different sizes of dust particles in organic waste gas and dry them, reduce the biological purification load of thesubsequent microbial filler filter tower, and improve the purification effect. The nutrient solution in the MBBR biofilm tank is recycled so that the utilization rate of the nutrient solution is improved, the regeneration rate and activity of the flora in the MBBR biofilm tank are improved, the sustainability of the organism is improved and the overall investment operation cost is reduced.

Owner:广东盈睿通环境科技有限公司

Multivalent group b meningococcal protein vaccine and preparation method thereof

ActiveCN104127869BGuaranteed Protection CoverageGood cross-protection antibody titersAntibacterial agentsBacterial antigen ingredientsAdjuvantMeningococcal carriage

Owner:BEIJING SANROAD BIOLOGICAL PROD CO LTD

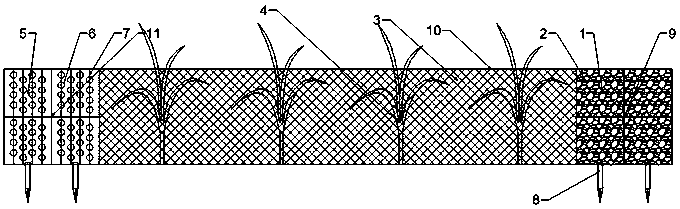

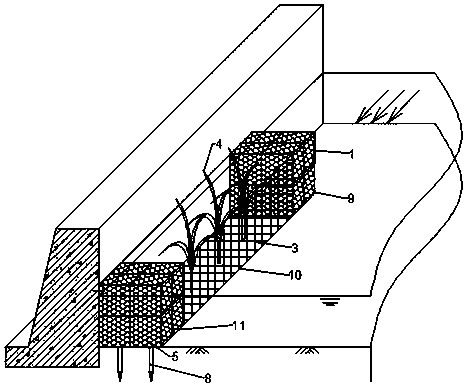

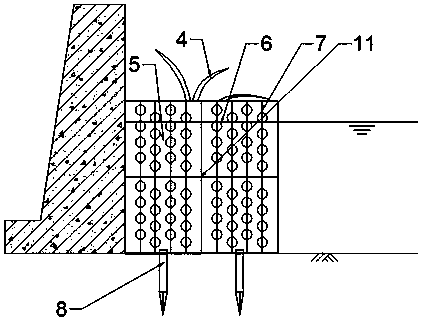

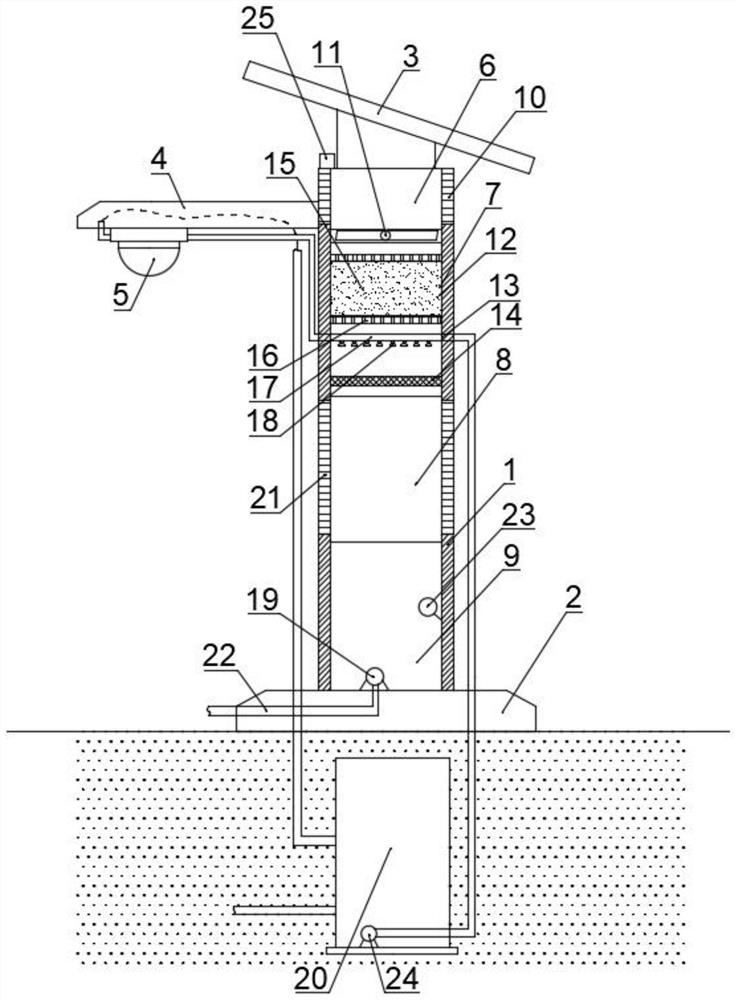

Ecological restoration system suitable for hard revetments of high-flow-rate polluted rivers

InactiveCN107698036ASlow down the flowAvoid damageBiological water/sewage treatmentContaminated waterways/lakes/ponds/rivers treatmentWater flowEngineering

The invention provides an ecological restoration system suitable for hard revetments of high-flow-rate polluted rivers. The system comprises an upstream permeable wall, a plant area and a downstream permeable wall, wherein the upstream permeable wall is connected with the plant area through an iron wire net, the plant area is connected with the downstream permeable wall through the iron wire net,bio-balls are arranged in the downstream permeable wall, and microorganisms are attached to the bio-balls; incoming water flows into the plant area at a lower flow rate after being dissipated and adsorbed by the upstream permeable wall, is purified by plants, then flows into the downstream permeable wall, is degraded by the microorganisms attached to the bio-balls and arranged in the downstream permeable wall and flows out of the system. The system has the advantages as follows: 1) energy dissipation can be effectively performed on high-flow-rate water, and impurities can be filtered and adsorbed; 3) sustainable ecological restoration can be performed on water; 4) the bio-balls are arranged in the downstream permeable wall, and the purification capacity is improved; 5) the erosion effect of the water on the revetments is weakened; 6) the overall process device of the system is made of an environment-friendly lightweight material, and the whole device is convenient to install, replace and maintain.

Owner:南京市长江河道管理处 +1

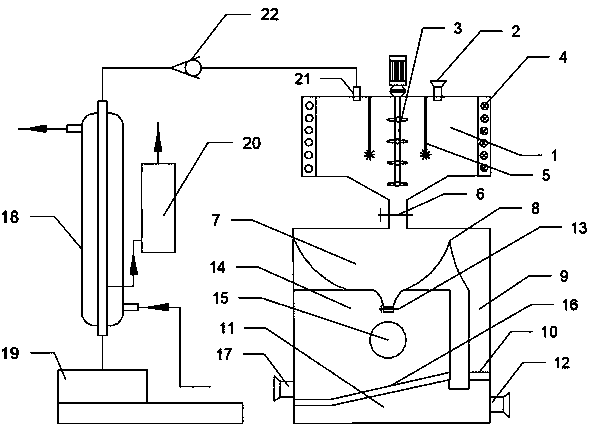

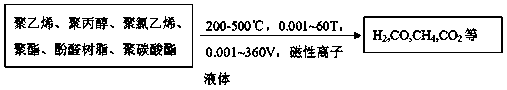

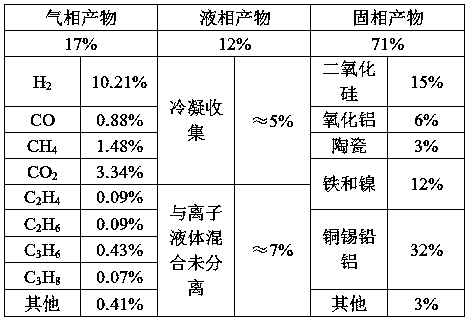

Method and device for recycling waste circuit boards through ion liquid

InactiveCN109967487AOvercome the disadvantages of high energy consumptionWide electrochemical windowTransportation and packagingSolid waste disposalParticulatesCatalytic pyrolysis

The invention discloses a method and a device for recycling waste circuit boards through ion liquid, and belongs to the technical field of solid waste resource development and utilization. The methodcomprises the steps of prilling the waste circuit boards, then mixing the waste circuit board particles and the magnetic ion liquid, heating the mixture, meanwhile, applying voltage on the mixture through an inert electrode or / and applying a magnetic field on the mixture through a magnetic induction loop, carrying out catalytic pyrolysis on the mixture at 200 to 500 DEG C, collecting a gas-phase product, and condensation recycling; and separating solid-phase and liquid-phase products, recycling a liquid phase, and magnetically separating a solid phase. According to the method and the device for recycling the waste circuit boards through the ion liquid provided by the invention, the ion liquid with a high catalytic performance is utilized, electricity or / and magnetism is / are additionally added for producing an electromagnetic coupling liquid phase catalysis effect on an organic matter base plate, the pyrolysis temperature is low, the micromolecule substance yield is high, a catalyst canbe recycled, and a pyrolysis three-phase product is high-value utilized.

Owner:KUNMING UNIV OF SCI & TECH

Method of producing propylene glycol

InactiveUS8378152B2High catalytic activityEfficient productionOxygen-containing compound preparationOrganic compound preparationHydrogenX-ray

Owner:MITSUI CHEM INC

Landfill leachate treatment system

PendingCN111792745ASmall footprintSmall effluent water qualityTreatment involving filtrationMultistage water/sewage treatmentAmmoniacal nitrogenEnvironmental engineering

The invention relates to a landfill leachate treatment system. The system comprises a garbage storage area, a liquid collection tank, a first sedimentation tank, an air flotation machine, a second sedimentation tank, a filtering device, an ammonia nitrogen stripping tower, a degassing tower and a clean water tank which are arranged in sequence. According to the invention, suspended impurities in landfill leachate are removed by utilizing the air flotation machine; fine impurities in a water body are removed through the filtering device; ammonia gas in the water body is removed through the ammonia nitrogen stripping tower; and finally, carbon dioxide in the water body is removed through the degassing tower, so purified water with good water quality is finally obtained. The whole treatment system is low in investment cost, small in occupied area, good in effluent quality and suitable for large-scale application and popularization.

Owner:中科建环有限责任公司

Anti-haze heat dissipation type solar street lamp

InactiveCN111810899AExtended service lifeImprove purification efficiencyCombination devicesMechanical apparatusActivated carbonThermodynamics

The invention discloses an anti-haze heat dissipation type solar street lamp, and relates to the technical field of street lamps, the anti-haze heat dissipation type solar street lamp comprises a lamppost, a lamp post is arranged at the upper part of the lamp post, an LED lamp is mounted on the lamp post, an inner cavity of the lamp post naturally forms an air outlet area, a purification area, anair inlet area and a pollution discharge area from top to bottom, a plurality of air outlet holes are formed in the side wall of the air outlet area, a fan, a filtering assembly, a spraying assemblyand a steel wire mesh layer are sequentially arranged in the purification area from top to bottom, the filtering assembly comprises an activated carbon layer and two grating plates arranged on the upper face and the lower face of the activated carbon layer respectively, the spraying assembly comprises a spraying pipe and a plurality of spraying heads installed on the lower side face of the spraying pipe, the two ends of the spraying pipe penetrate through the lamp pole wall, one end of the spraying pipe is connected with a circulating water tank through a first water pump, and the other end penetrates through a heat dissipation area of the lamp and then is connected to the circulating water tank, a plurality of air inlet holes are formed in the side wall of the air inlet area, and the bottom end of the blowdown area is connected with a water outlet pipe. The street lamp can be cooled, and haze can be removed at the same time.

Owner:江苏丰登光电科技有限公司

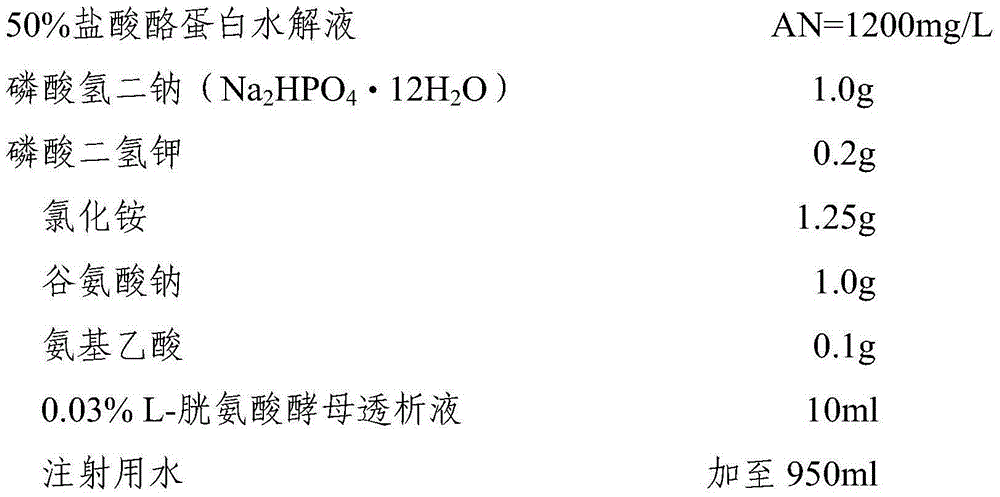

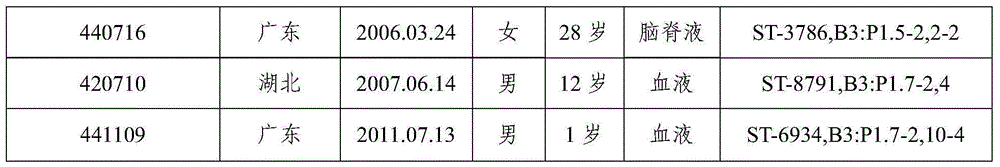

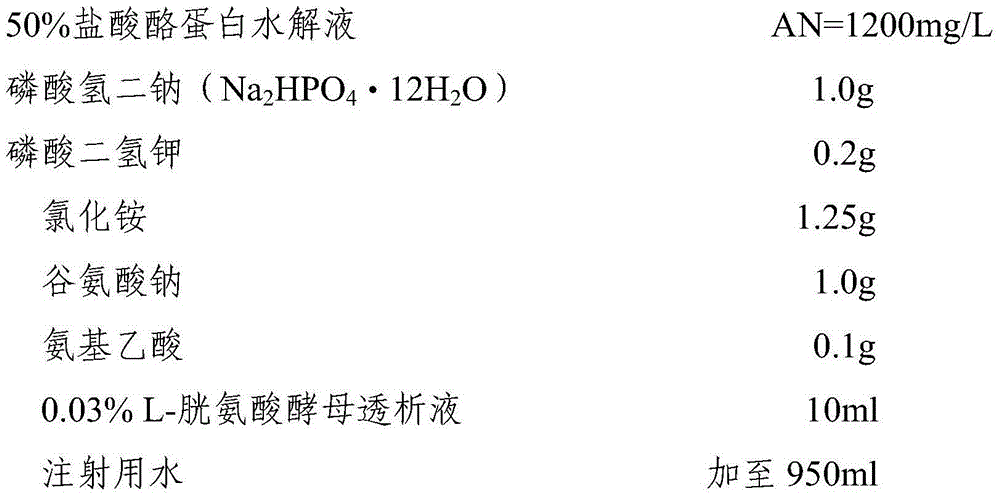

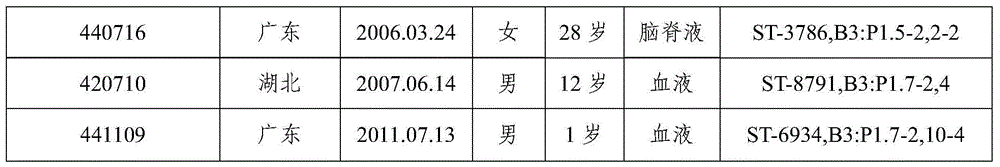

Multivalent group B meningococcal protein vaccine and preparation method thereof

ActiveCN104127869AGuaranteed Protection CoverageGood cross-protection antibody titersAntibacterial agentsBacterial antigen ingredientsAdjuvantMeningococcal carriage

The invention provides a multivalent group B meningococcal protein vaccine. The multivalent group B meningococcal protein vaccine is a multivalent combined vaccine comprising outer menbrane vesicle (OMV) proteins of group B meningococcus strain CMCC29356, strain CMCC29361, strain xrsw341215 having preservation number of CGMCC No.8982 and strain xrsw210902 having preservation number of CGMCC No.8981, and optionally comprises a medicinal excipient and / or an adjuvant. The multivalent group B meningococcal protein vaccine has wide cross protection antibody titers for prevention of group B epidemic cerebrospinal meningitis around the world, and has good cross protection effects on group A and group C epidemic cerebrospinal meningitis. The invention provides a whole production technology of the multivalent group B meningococcal protein vaccine. The production technology is suitable for large scale production. A research result shows that the multivalent group B meningococcal protein vaccine has good immunogenicity, reliable safety and stable immunization endurance.

Owner:BEIJING SANROAD BIOLOGICAL PROD CO LTD

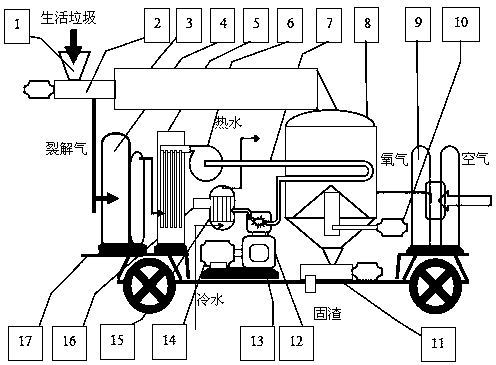

Domestic garbage treatment method, device and engineering vehicle

InactiveCN105642655BHigh calorific valueReduce purification loadSolid waste disposalHigh concentrationCombustion chamber

The invention relates to a domestic garbage treatment method, a device and a mobile machinery shop, and aims to provide the domestic garbage treatment method to prevent generation of harmful substances to reduce environmental pollution. The domestic garbage treatment method comprises the garbage treatment steps of: drying-internal combustion cracking under a high-concentration oxygen environment-deacidification-filtration-secondary cracking-combustion; (a) drying: garbage is dried in a rotary drying kiln; (b) internal combustion cracking under high-concentration oxygen environment: the internal combustion cracking is performed for the garbage, dried by the rotary drying kiln, in an oxygen control cracking furnace under the high-concentration oxygen environment; (c) deacidification: cracking gas generated by the oxygen control cracking furnace is deacidified by a cracking gas purifier; (d) filtration: the deacidified cracking gas is filtered by a high-temperature membrane filter; (e) secondary cracking: the deacidified and filtered cracking gas is secondarily cracked in a high-temperature cracking tube; and (f) combustion: the secondarily cracked cracking gas is fed in a cracking gas combustion chamber for total combustion.

Owner:中能恒源环保科技有限责任公司

System and method for treating radioactive waste through plasma high-temperature pyrolysis melting

ActiveCN114420336AImprove pyrolysis efficiencyQuality improvementRadioactive decontaminationDust controlAir pump

The invention belongs to the technical field of radioactive waste treatment, and particularly discloses a system and method for treating radioactive waste through plasma high-temperature pyrolysis melting, and the system comprises a plasma high-temperature melting furnace, a plasma torch communicated with the melting furnace, a feeding device and a combustible gas supplementary combustion device. The air pump and the two-stage dust removal device are communicated with the combustion device, the nitric oxide removal device is communicated with the combustion device and the two-stage dust removal device, the heat exchange cooling device is communicated with the dust removal device, and the induced draft fan and the chimney are communicated with the heat exchange cooling device. The method comprises the steps that after radioactive waste is fed, the plasma torch heats and melts the waste in the melting furnace to generate radioactive waste gas and a glass melting solidified body, tail gas generated by combustion is subjected to nitrogen oxide removal, two-stage dust removal, heat exchange cooling, deacidification, demisting, cooling and purification, and then the tail gas is discharged. The pyrolysis efficiency of radioactive waste can be improved, the tail gas purification treatment load is reduced, the tail gas emission quality is improved, and a stable glass melting solidified body is generated.

Owner:SOUTHWESTERN INST OF PHYSICS +1

A device for photocatalytic advanced treatment of wastewater

InactiveCN105776686BEasy to handleStrong oxidation abilityEnergy based wastewater treatmentMultistage water/sewage treatmentWastewaterThin layer

The invention belongs to the field of water treatment application, and provides a device for photocatalytic advanced treatment of wastewater, which includes a water inlet pipe, a nozzle and a pool body, and the water inlet pipe is connected to the pool body through a nozzle; the pool body includes a photocatalytic part and multiple The medium combination treatment part, the multi-media combination treatment part is located directly below the photocatalytic part; the present invention is an advanced treatment device composed of thin water film multi-layer oxidation and multi-media combination of wastewater, which can efficiently treat waste water It has strong oxidizing ability, good adaptability, mild degradation conditions, no need to add oxidant, and the treatment process is cheap, safe and easy to operate.

Owner:JIANGSU UNIV

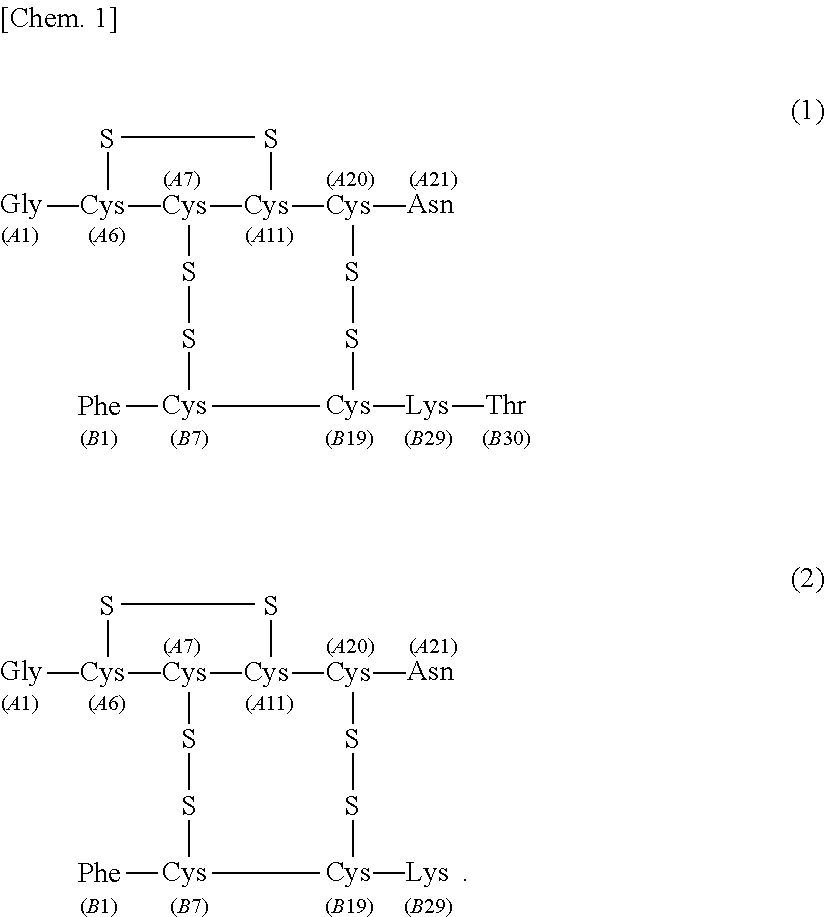

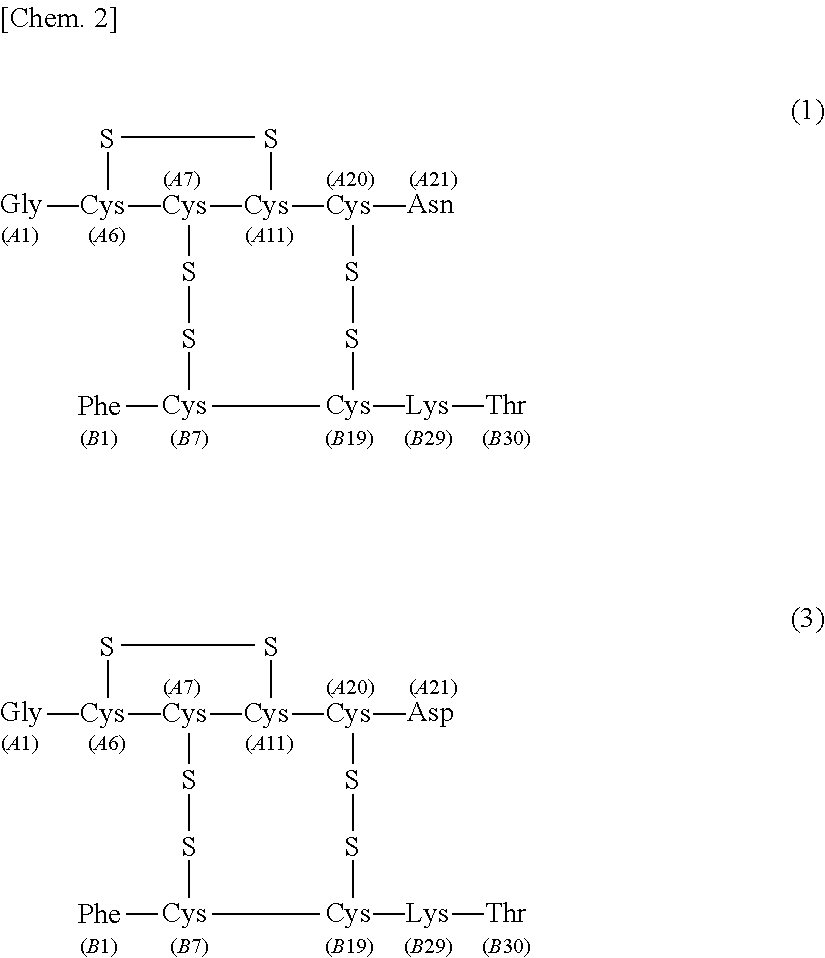

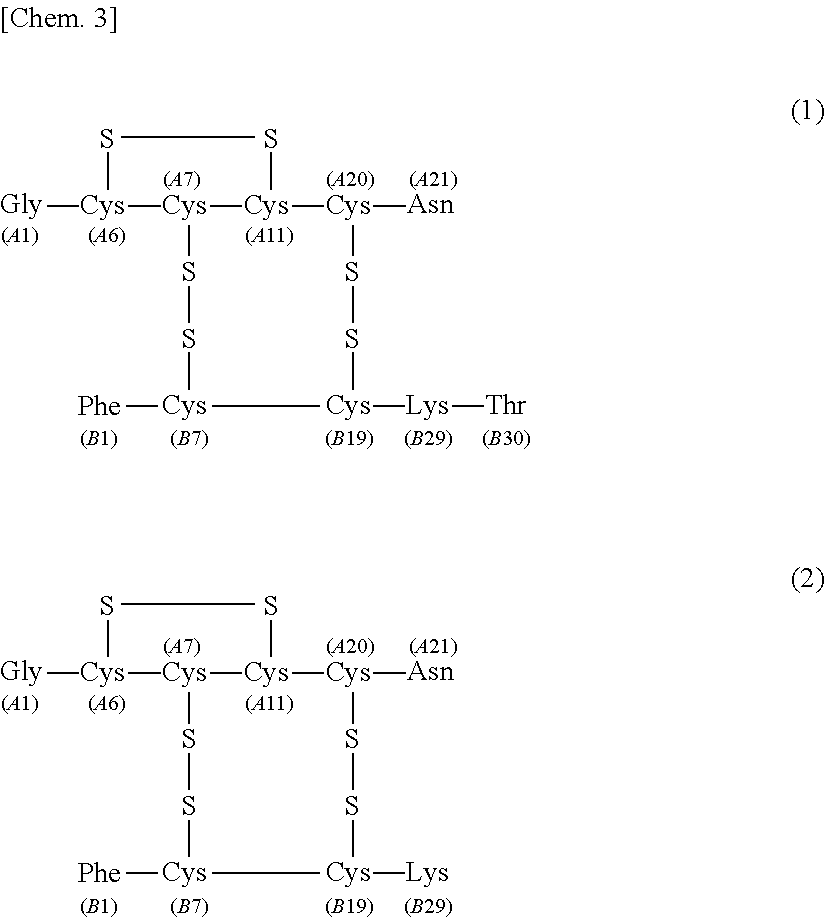

Separating agent for human insulin purification and human insulin purification method

InactiveUS20190359649A1Difficult to separateReduction in production constraintChromatographic cation exchangersOrganic anion exchangersPurification methodsSeparating agent

The present invention is related to a separating agent for the purification of human insulin, ensuring that human insulin can be recovered in high yield when isolating human insulin from a solution containing human insulin and a specific insulin under specific liquid chromatography separation conditions by using the separating agent.

Owner:MITSUBISHI CHEM CORP

Two-stage chlorination roasting-alkali leaching method extracts lithium from lepidolite and prepares lithium carbonate

ActiveCN108118143BLow melting pointImprove reaction kineticsProcess efficiency improvementLithium carbonateWater chlorination

The invention discloses a method for preparing lithium carbonate from lepidolite by extracting lithium from lepidolite by a two-stage chlorination roasting-alkali leaching method, comprising the following steps: (1) grinding lepidolite ore and calcium chloride and adding it to chlorine mixing in the ammonium chloride solution to obtain green pellets; (2) performing one-stage roasting on the green pellets obtained in step (1) at 150-300°C, and then performing second-stage roasting at 500-800°C to obtain clinker; (3) leaching the clinker obtained in step (2) with water, and filtering to obtain the leachate; (4) adding carbonate solution to the leachate obtained in step (3), stirring and filtering to obtain mother liquor and filter residue, collecting the filter residue to obtain carbonic acid lithium. In the present invention, each step cooperates and acts synergistically, and the process of extracting lithium from lepidolite to prepare lithium carbonate is environmentally friendly, has low energy consumption, low cost, high extraction efficiency, and has broad industrial application prospects.

Owner:CENT SOUTH UNIV

Pure oxygen direct combustion system using liquid metal

ActiveUS10240786B2Reduce purification loadPoint becomes highMaintainance of heating chambersCharge manipulationCombustion systemDirect combustion

A pure oxygen direct combustion system using a liquid metal according to the present invention comprises: a reactor for receiving a liquid metal; a heat exchanger, connected to the bottom of the reactor, for exchanging heat for the liquid metal; a circulation pump, connected to the heat exchanger, for circulating the incoming liquid metal; a nozzle, connected to the circulation pump and disposed on the reactor; a reduction unit, connected to the circulation pump, for performing a reduction for the oxidized liquid metal; and a separation unit, connected to the reactor and the reduction unit, wherein the particles of the liquid metal injected from the nozzle are subjected to sensible heat from the gas generated from the reactor, heat-exchanged by the heat exchanger and regenerated by the reduction unit, and then supplied back to the reactor.

Owner:KOREA INST OF IND TECH

Power plant industrial wastewater treatment device

PendingCN112321096AEasy to rinseEasy to cleanSpecific water treatment objectivesTreatment involving filtrationIndustrial wastewater treatmentActivated carbon

The invention relates to a power plant industrial wastewater treatment device, which comprises an anaerobic tank, a water inlet pipe is arranged on the outer surface, close to the upper portion of theleft side, of the anaerobic tank, an anoxic tank is arranged on the outer surface, close to the right side, of the water inlet pipe, and an oxygen discharging pipeline is arranged in the middle, close to the upper side, of the outer surface of the anoxic tank; an aerobic tank is arranged on the outer surface, close to the right side, of the anoxic tank, and a secondary sedimentation tank is arranged on the outer surface, close to the right side, of the aerobic tank. According to the wastewater treatment device, an activated carbon plate and a biological nano-membrane plate can be convenientlycleaned, internal components of the device can be flushed without disassembly, the cleaning process of the internal components of the device is simplified, convenience is brought to a user, the purification effect of the device in the secondary sedimentation process is kept in the optimal state, the sewage is subjected to double purification processes of nitrogen and phosphorus removal, so that the operation steps of subsequent sewage treatment procedures are reduced.

Owner:フアネングチンメイルイジンパワージェネレーションカンパニーリミテッド

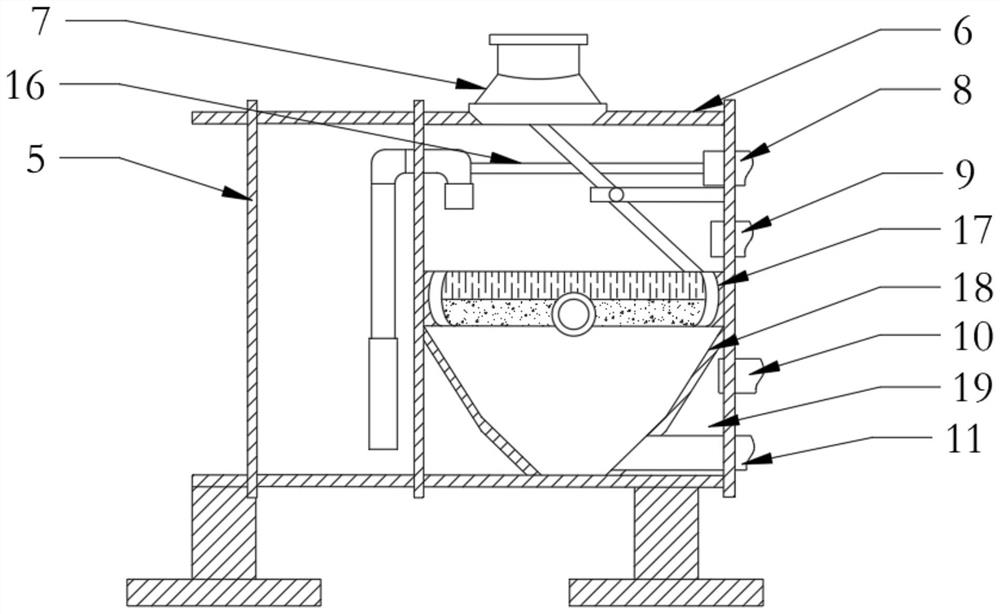

A method and a sintering machine for recycling flue gas to form a multi-stage secondary combustion chamber for incinerating solid waste flue gas

ActiveCN105674290BIncrease full circulationEasy to handleEmission preventionIncinerator apparatusThermodynamicsCombustion chamber

The invention provides a method for circulating flue gas on a sintering machine to form a multi-stage secondary combustion chamber for incineration disposal of solid waste flue gas. The sintering machine is utilized as main equipment for disposing solid waste, flue gas generated in the incineration process is circularly disposed, and the multi-stage secondary combustion chamber is formed through a next-stage combustion material layer. Specifically, a plurality of independent flue gas hoods are sequentially arranged above an incineration section of the sintering machine, and materials of the incineration section are isolated from external air; each flue gas hood corresponds to one or more draught hoods below the incineration section of the sintering machine, a flue gas inlet is formed in each flue gas hood, and each flue gas inlet is connected with a negative-pressure air draft pipeline of the previous draught hood below the incineration section; all flue gas generated by combustion of the preceding stage is collected to an air inlet position of the next stage to be mixed with distributed fresh air to be used as a combustion gas source of this stage, the flue gas passes through a high-temperature combustion zone in the incineration process to be subjected to secondary combustion, and full-amount circulating combustion of the flue gas is achieved; and combustible substances existing in the flue gas are thoroughly combusted, and the construction investment and operating cost of a flue gas purification system project are reduced.

Owner:CHONGQING ANGRUIYUE SCI & TECH

Preprocessing method suitable for analyzing estrogen and bisphenol A in complex matrix solid sample

InactiveCN102435681BReduce purification loadImprove purification effectComponent separationLiquid chromatography mass spectroscopyPoultry manure

Owner:BEIJING NORMAL UNIVERSITY

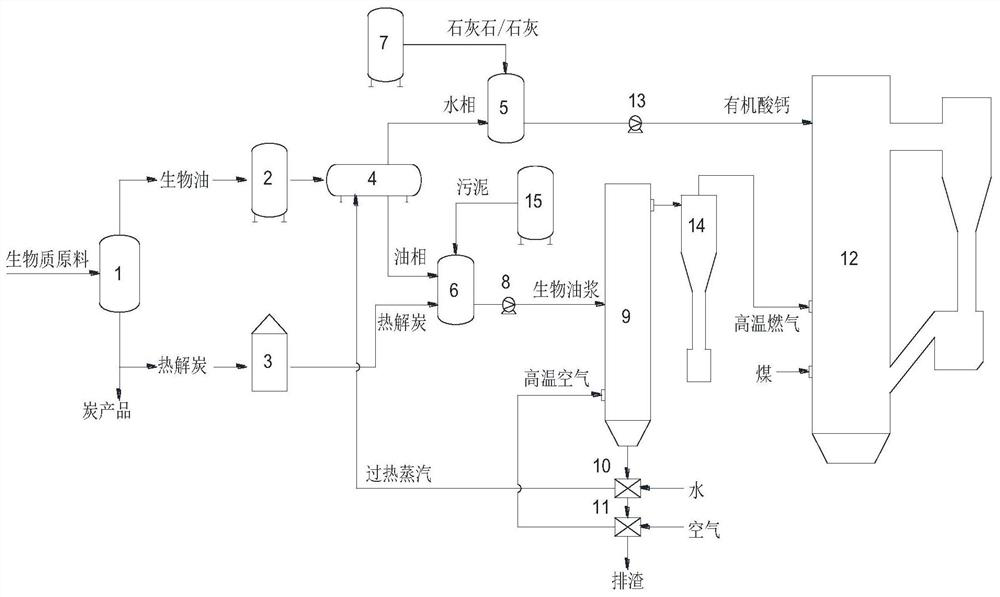

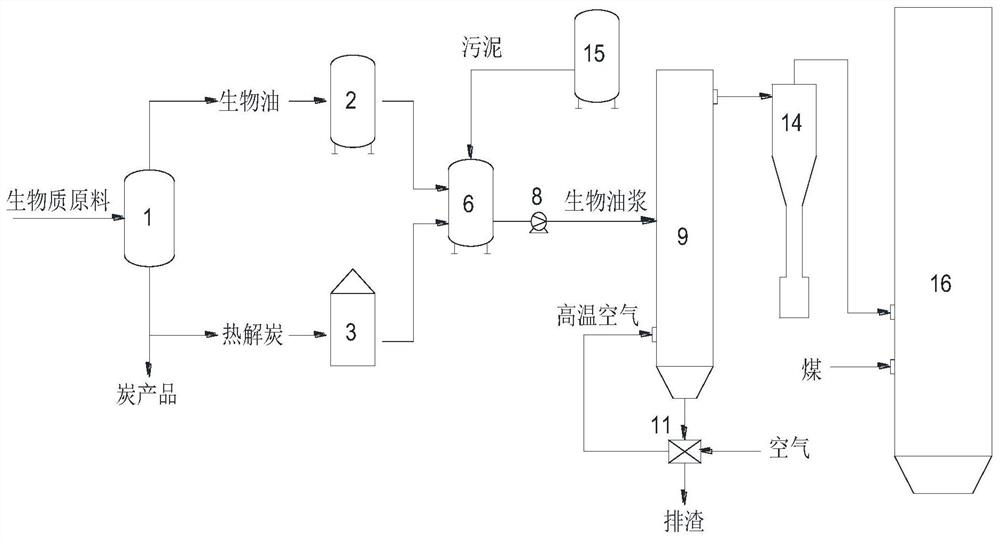

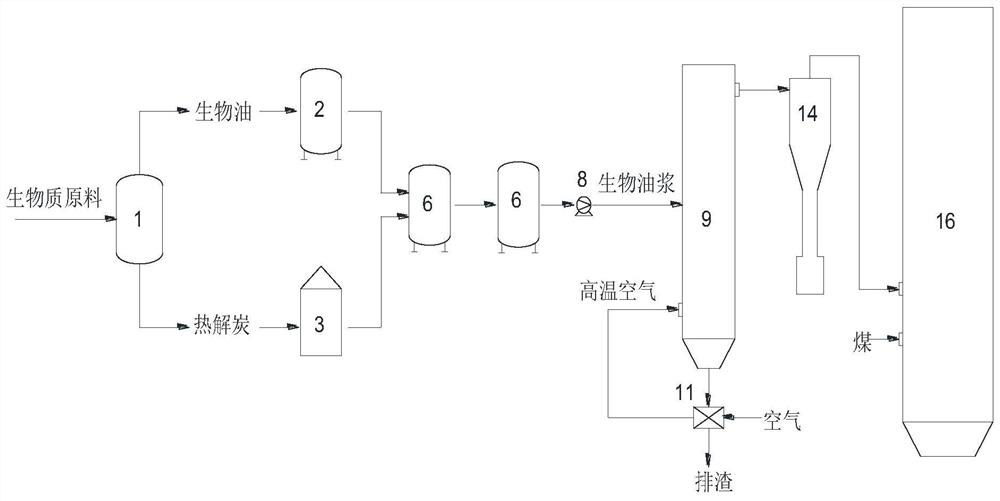

A coal-fired coupled biomass power generation system and method

The invention relates to a coal-fired coupled biomass power generation system and method, belonging to the technical field of biomass energy. The system includes biomass pyrolysis unit, storage processing unit, pressurized gasification unit and coal-fired power generation unit. First, the biomass raw material is converted into bio-oil and pyrolytic carbon by pyrolysis nearby, and then processed into bio-oil slurry and calcium organic acid; the bio-oil slurry uses a pressurized gasifier to produce high-temperature gas, and directly sends it to a coal-fired boiler for co-combustion generate electricity. The invention realizes the efficient conversion and utilization of waste resources such as biomass and sludge, and can meet the large-scale coal-fired power plant coupled with biomass power generation scale requirements, and at the same time co-produce high value-added carbon products, organic acid calcium can also be used for The desulfurization and denitrification in the circulating fluidized bed boiler has a good application prospect.

Owner:HUAZHONG UNIV OF SCI & TECH

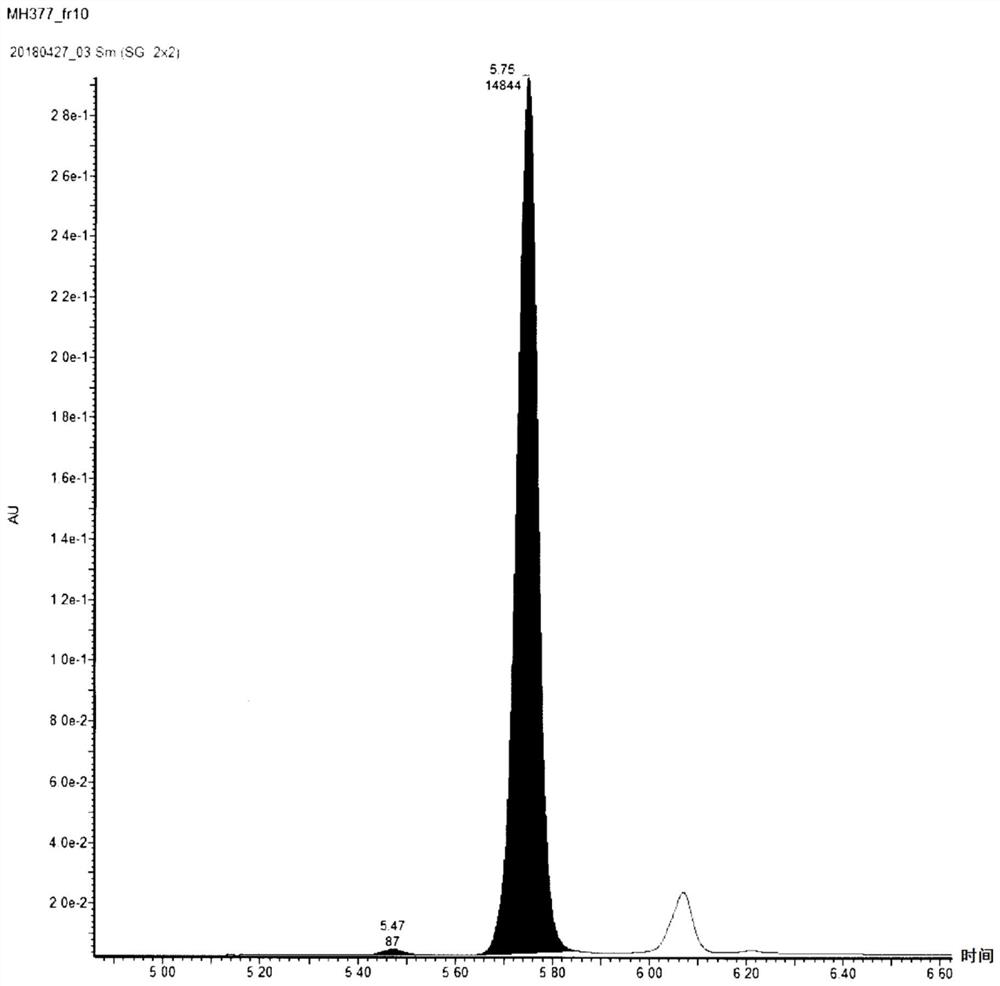

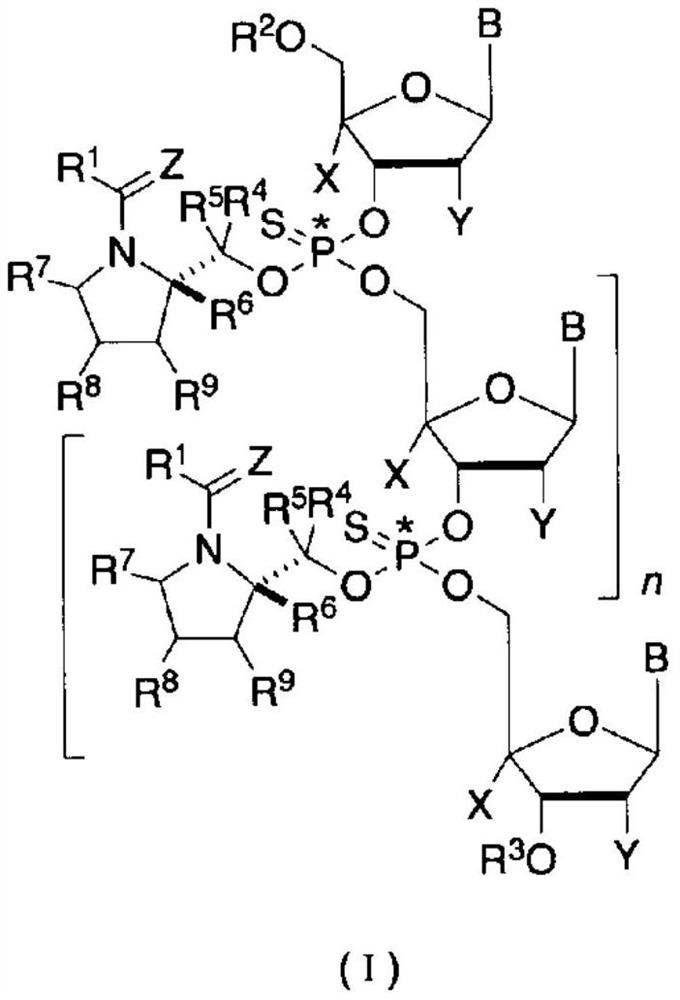

Optically active fragment for synthesizing stereocontrolled oligonucleotide, method for producing same, and method for synthesizing stereocontrolled oligonucleotide using same

PendingCN114269764AReduce the number of processesReduce purification loadSugar derivativesOrganic chemistry methodsAcyl groupEther

Provided are: an optically active fragment for synthesizing a stereocontrolled oligonucleotide represented by formula (I); a method for producing the optically active fragment; and a method for synthesizing a stereocontrolled oligonucleotide using the optically active fragment. In the formula, B is a protected / unprotected nucleoside base, R1 is a substituted / unsubstituted aliphatic group, R2 and R3 are DMTr groups or-P (R11) (NR12) 2, R11 is OCH2CH2CN, SCH2CH2CN and the like, and R12 is a substituted / unsubstituted aliphatic group or aromatic group; x is H, an alkyl group, an O-alkyl group or the like, Y is H, NHR13, a halogen or the like, or an acyl group, an ether group, a silyl group protected hydroxyl group or forms an X-Y bond with X, and n is an integer from 0 to 4 (inclusive).

Owner:株式会社纳蒂亚斯

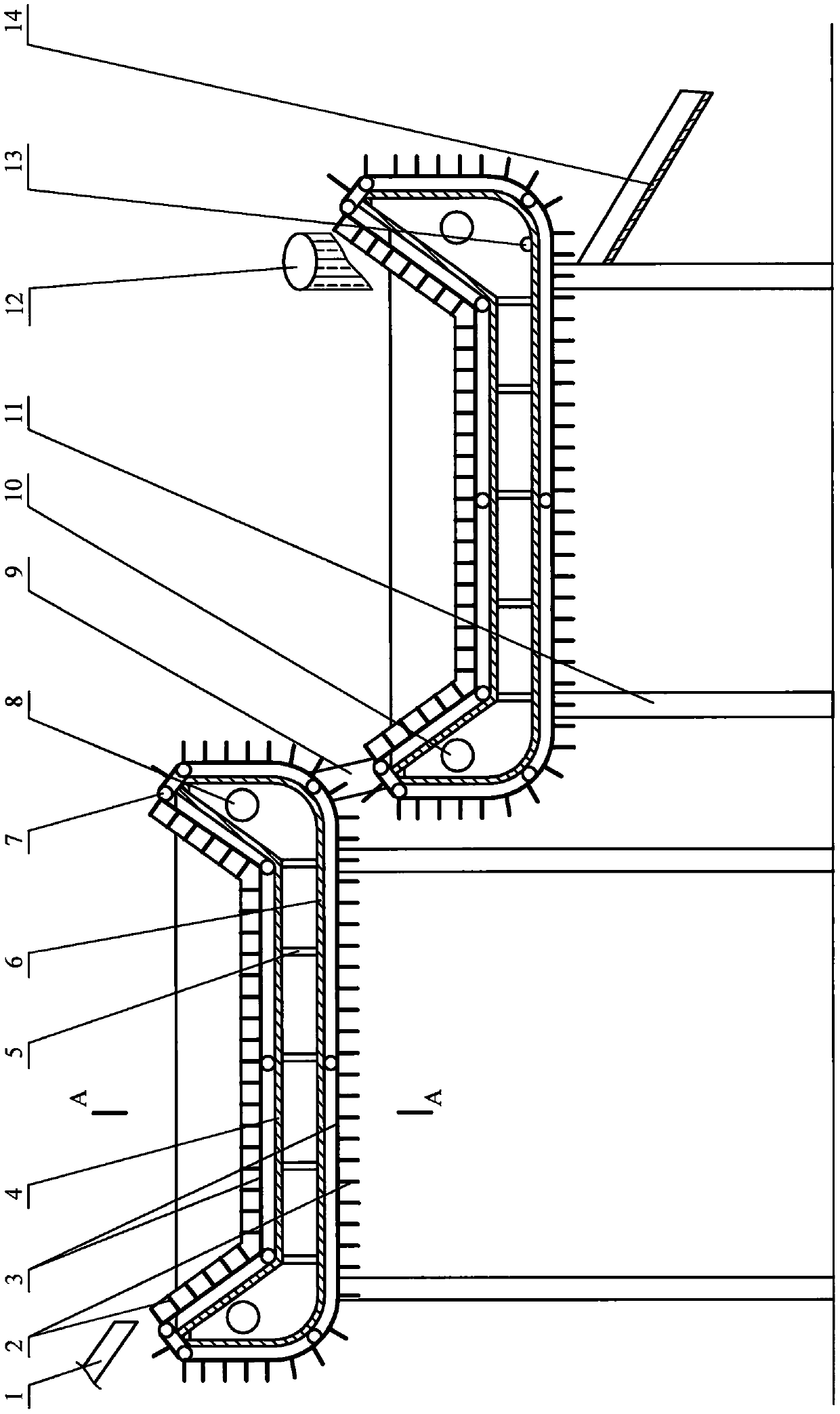

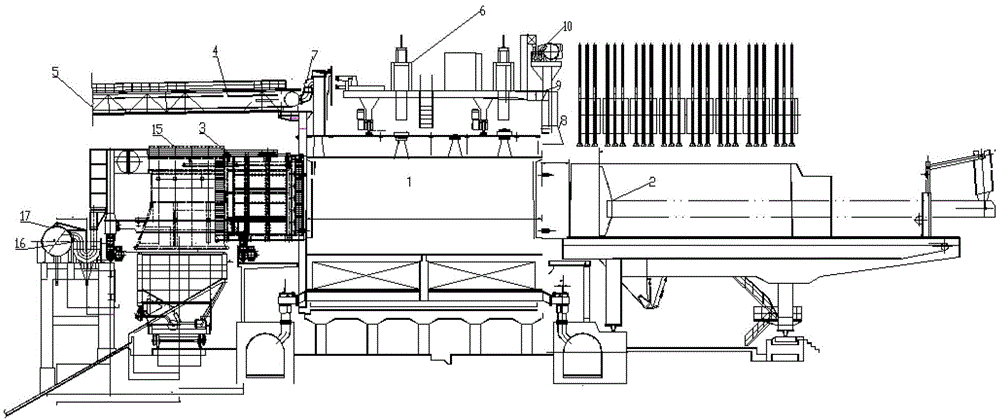

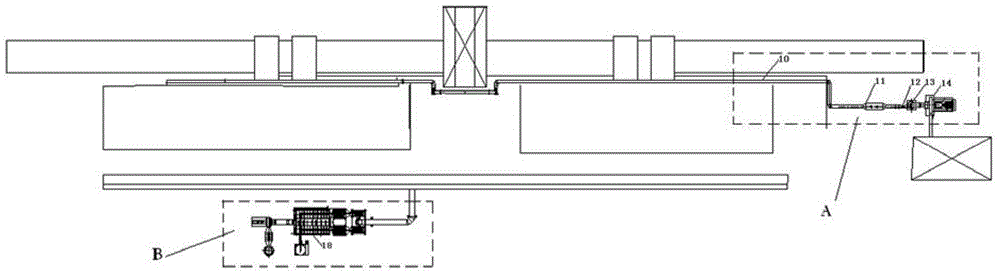

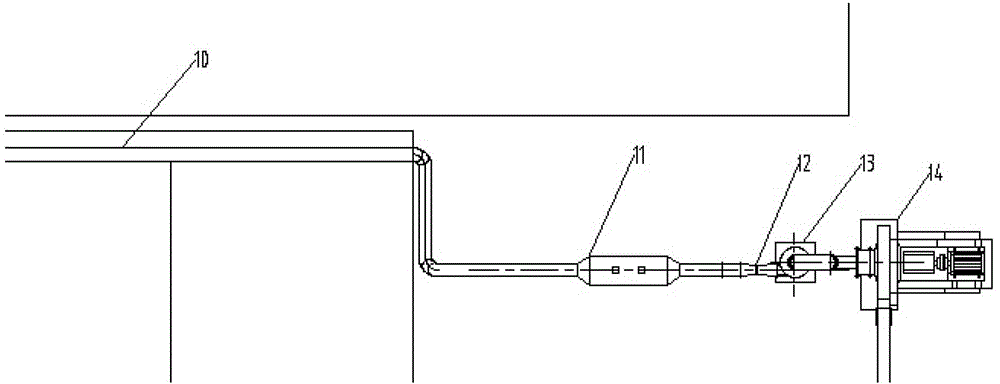

Leakage-free coaling and coke pushing combined smoke purifying and recycling system and technology for coke oven

InactiveCN102746859BSolve the deficiency of wasting a lot of energyFix the leakCharging-discharging device combinationsOven incrustations prevention/removalGas collecting tubeChemical products

The invention discloses a leakage-free coaling and coke pushing combined smoke purifying and recycling system and a technology for a coke oven, which comprises the coke oven (1), a coke pushing device (2) and a coke guide (3), wherein a double-U-shaped water sealing smoke guide car (6) and a high-pressure ammonia water system (7) are connected with a furnace top gas collecting tube (4) through which the coke oven is led to a chemical product recycling and purifying system (5); a smoke collecting hood (8) is equipped on an oven side furnace end of the coke oven; the smoke collecting hood is connected with a U-shaped water sealing dust-removal dry tube (10) through a leakage-free seal connecting device (9) equipped on the double-U-shaped water sealing smoke guide car; an automatic ignition burning device (11), a Venturi dust-removal device (12), a desulfurization system (13) and a fan (14) are connected in sequence behind the U-shaped water sealing dust-removal dry tube; and a discharge pipe of the fan is led to a quenching tower. The leakage-free coaling and coke pushing combined smoke purifying and recycling system and the technology for the coke oven are low in power consumption, low in investment and good in dust removal effect, and fit for all coke ovens.

Owner:冯书辉

Wet type dual-collecting and fume purifying apparatus

InactiveCN1185039CEfficient removalReduce purification loadUsing liquid separation agentSprayerEngineering

The invention is a kind of dust catching and smoke clarifying device which uses clarifier to form foam layer. It has foam clarifier, there's sprayer, upper and nether net board in the barrel. The foam room is between the two boards. The smoke inlet and outlet of foam clarifier are set on the upper and nether part. The dust outlet is set on the bottom of the barrel and connects with dust gathering box. There's an axis in the barrel which connects with the axis of the electromotor. The axis in the foam room connects some vanes; there's circular water box and clarifier box by the side of the barrel.

Owner:杨长明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com