Landfill leachate treatment system

A landfill leachate and treatment system technology, applied in the field of landfill leachate treatment systems, can solve the problems of impact on normal operation of sewage treatment plants and high investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

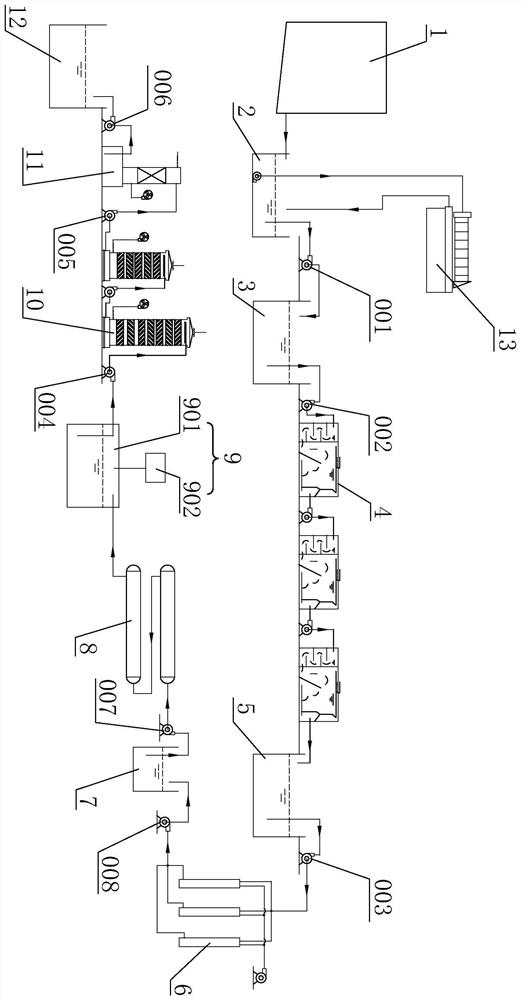

[0026] see figure 1 , the landfill leachate treatment system of this embodiment includes a garbage storage area 1, a liquid collection tank 2, a first sedimentation tank 3, an air flotation machine 4, a second sedimentation tank 5, a filter device, an ammonia nitrogen stripping tower 10 and a dewatering tank. Gas tower 11 and clean water pool 12.

[0027] The bottom liquid collection pipe of the garbage storage area 1 is connected to the liquid collection pool 2, the garbage storage area 1 is used to store garbage, and the leachate produced by the garbage flows into the liquid collection pool 2 after being collected by the liquid collection pipe at the bottom. Generally, the liquid collection pool 2 is usually greater than 100m 3 . The supernatant of the liquid collection tank 2 is sucked into the first sedimentation tank 3 by the first suction pump 001, and the first sedimentation tank 3 can be used for the precipitation of garbage permeate, and the heavy impurities are dep...

Embodiment 2

[0035] On the basis of embodiment one, the filter device of the present embodiment comprises SMBR ultrafiltration membrane 6 and RO reverse osmosis membrane 8, and the water inlet end of described SMBR ultrafiltration membrane 6 is connected with described second sedimentation tank 5, and water outlet The end is connected to the water inlet end of the RO reverse osmosis membrane 8, and the water outlet end of the RO reverse osmosis membrane 8 is connected to the ammonia nitrogen stripping tower 10.

[0036] Among them, the SMBR ultrafiltration membrane only allows water molecules, beneficial minerals and trace elements in the water to pass through, bacteria and colloids, rust, suspended solids, sediment, macromolecular organic matter, etc. The ultrafiltration membrane is intercepted, thereby realizing the purification process of the water body; water molecules can pass through the RO reverse osmosis membrane, while impurities such as inorganic salts, heavy metal ions, organic m...

Embodiment 3

[0040] On the basis of embodiment two, the third sedimentation tank 7 is also provided between the SMBR ultrafiltration membrane 6 and the RO reverse osmosis membrane 8 of the present embodiment, and the drain end of the SMBR ultrafiltration membrane 6 is connected to the first Three sedimentation tanks 7, the sedimentation tank is used to store the water treated by the SMBR ultrafiltration membrane, the water inlet end of the RO reverse osmosis membrane 8 is connected to the third sedimentation tank 7 through the seventh suction pump 007 Below the liquid level, the reverse osmosis membrane takes water in the third sedimentation tank, and the design of the third sedimentation tank can provide a buffer between the SMBR ultrafiltration membrane and RO reverse osmosis membrane to solve the SMBR The ultrafiltration membrane and the RO reverse osmosis membrane have different processing speeds.

[0041] Preferably, the drain pipe of the SMBR ultrafiltration membrane 6 is also provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com