Domestic garbage treatment method, device and engineering vehicle

A technology of domestic waste and treatment device, applied in the direction of solid waste removal, etc., can solve the problems of increasing the harm of nitrogen oxides, unacceptable to the public, secondary air pollution, etc., to reduce the treatment cost, avoid the production of nitrogen oxides, Effects of Clean Combustion Emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

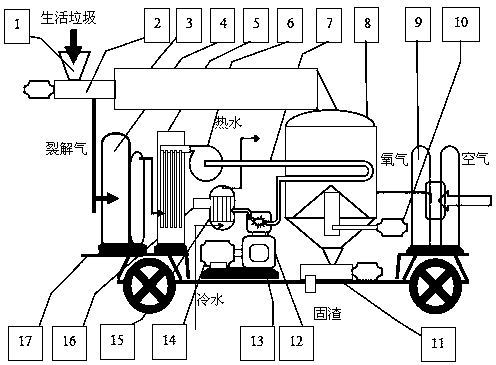

[0025] Such as figure 1 , figure 2 As shown, the present embodiment is a domestic waste treatment engineering vehicle, which has a vehicle body 17 and a domestic waste treatment device installed on the vehicle body. The domestic waste treatment device is composed of a garbage cracking device, a cracking gas processing device and a recycling device.

[0026] In this example, the garbage cracking device has a garbage feeding mechanism 1, a rotary drying kiln 3 and an oxygen-controlled cracking furnace 8 (model: JYO1, provided by Changzhou Jieyuan Environmental Protection Technology Co., Ltd. according to the daily garbage processing capacity), and a garbage feeding mechanism 1 A rubbish conveying mechanism 2 is arranged between the feed port of the rotary drying kiln 3, and the discharge port of the rotary drying kiln 3 is connected to the feed port at the upper end of the oxygen-controlled cracking furnace 8, which is connected with the pressure swing adsorption oxygen genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com