System and method for treating radioactive waste through plasma high-temperature pyrolysis melting

A radioactive waste and plasma technology, applied in radioactive purification, nuclear engineering, etc., can solve problems such as uncontrollable temperature rise, achieve the effects of improving combustible gas quality, reducing processing load, and improving pyrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

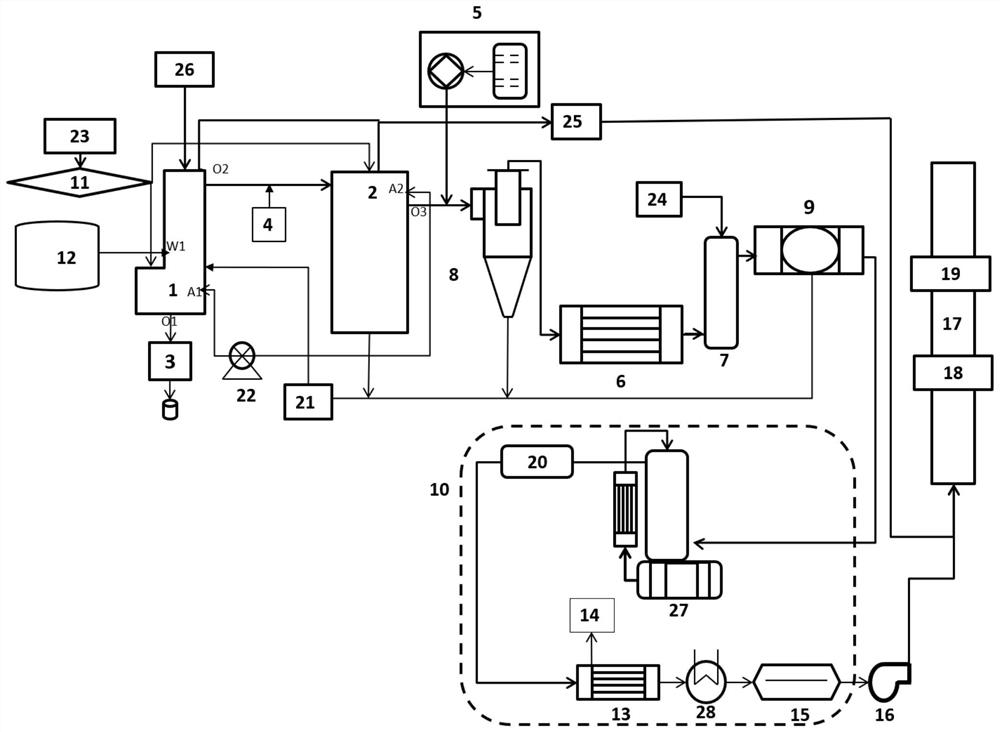

[0067] Such as figure 1 As shown, the process of high-temperature pyrolysis and melting treatment of low-level radioactive waste from nuclear power plants is as follows:

[0068] The low-level radioactive waste from the nuclear power plant enters the plasma high-temperature melting system from the top of the plasma high-temperature melting furnace 1 through the feeding device 26, and passes through the plasma high-temperature melting furnace 1 successively during the process of falling into the plasma high-temperature melting furnace 1. Drying zone, pyrolysis zone, reaction zone, melting zone. The drying area is located at the top of the plasma high-temperature melting furnace 1; before the pyrolysis area and the reaction area, there is an atomized water inlet connected to the atomized pure water tank 12, and after the radioactive waste enters the furnace, it absorbs heat through air heat transfer and raises its temperature to 400 ° C, and Pyrolysis into small molecular subst...

Embodiment 2

[0072] Such as figure 1 As shown, the process of high-temperature pyrolysis and melting treatment of medical waste is as follows:

[0073] The medical waste enters the plasma high-temperature melting system through the feeding device 26 from the top of the plasma high-temperature melting furnace 1 through the feeding device 26, and is fed into the plasma high-temperature melting furnace 1 during the falling process, and then passes through the drying zone, pyrolysis zone, and reaction zone, melting zone. The drying zone is located at the top of the plasma high-temperature melting furnace 1, and an atomized water inlet W1 is set before the pyrolysis zone and the reaction zone. After the waste enters the plasma high-temperature melting furnace 1, it heats up and absorbs heat through air heat transfer and pyrolyzes into small molecular substances; The organic components are pyrolyzed into small molecular flammable gases and leave the plasma high-temperature melting furnace 1 fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com