Method and device for continuously rinsing chemical activated carbon

A technology of chemical activation and activated carbon, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of slow filtration, low production efficiency, trouble and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

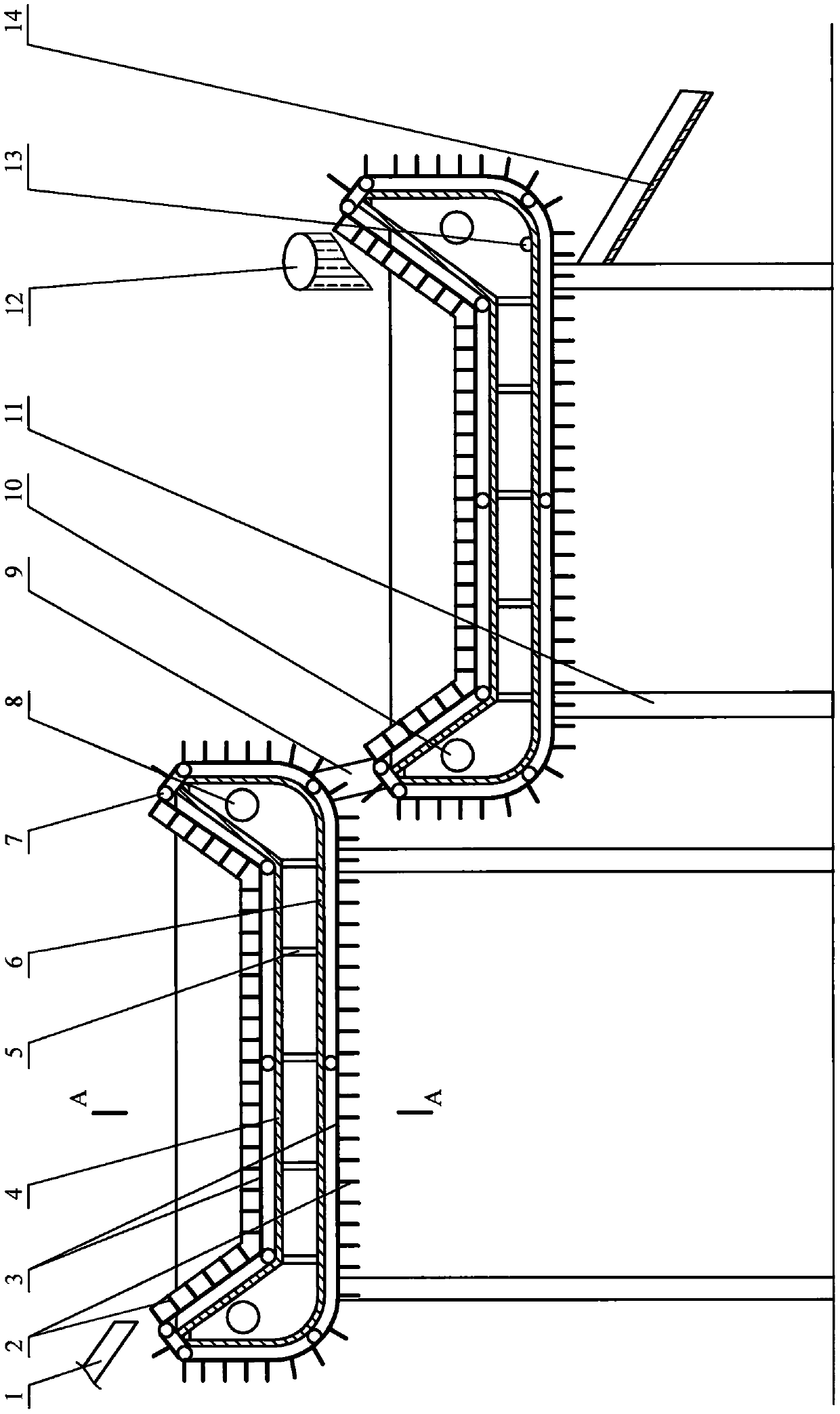

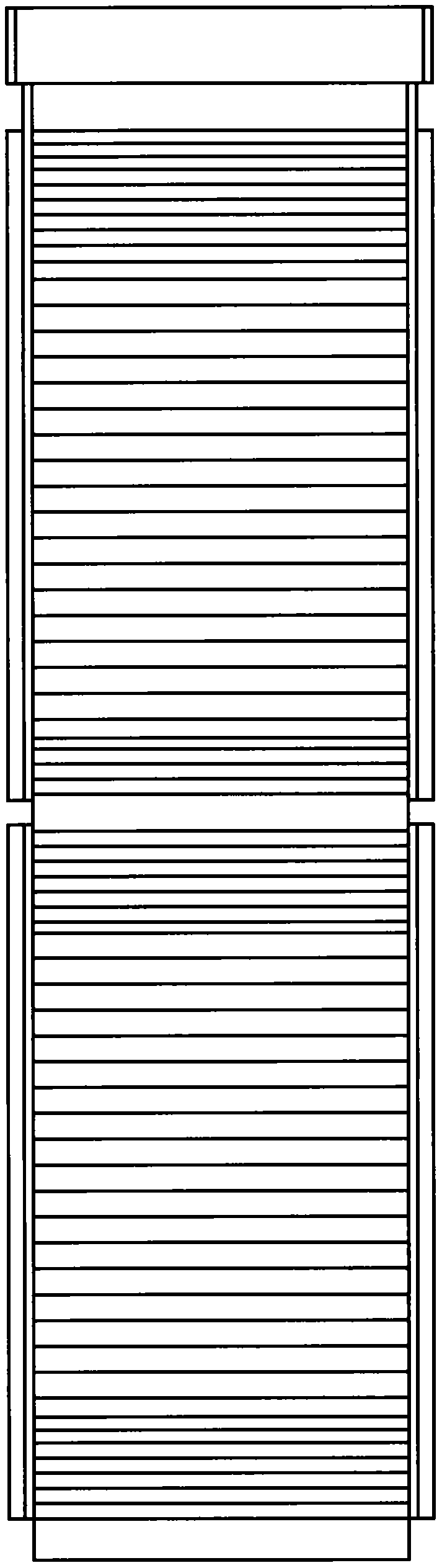

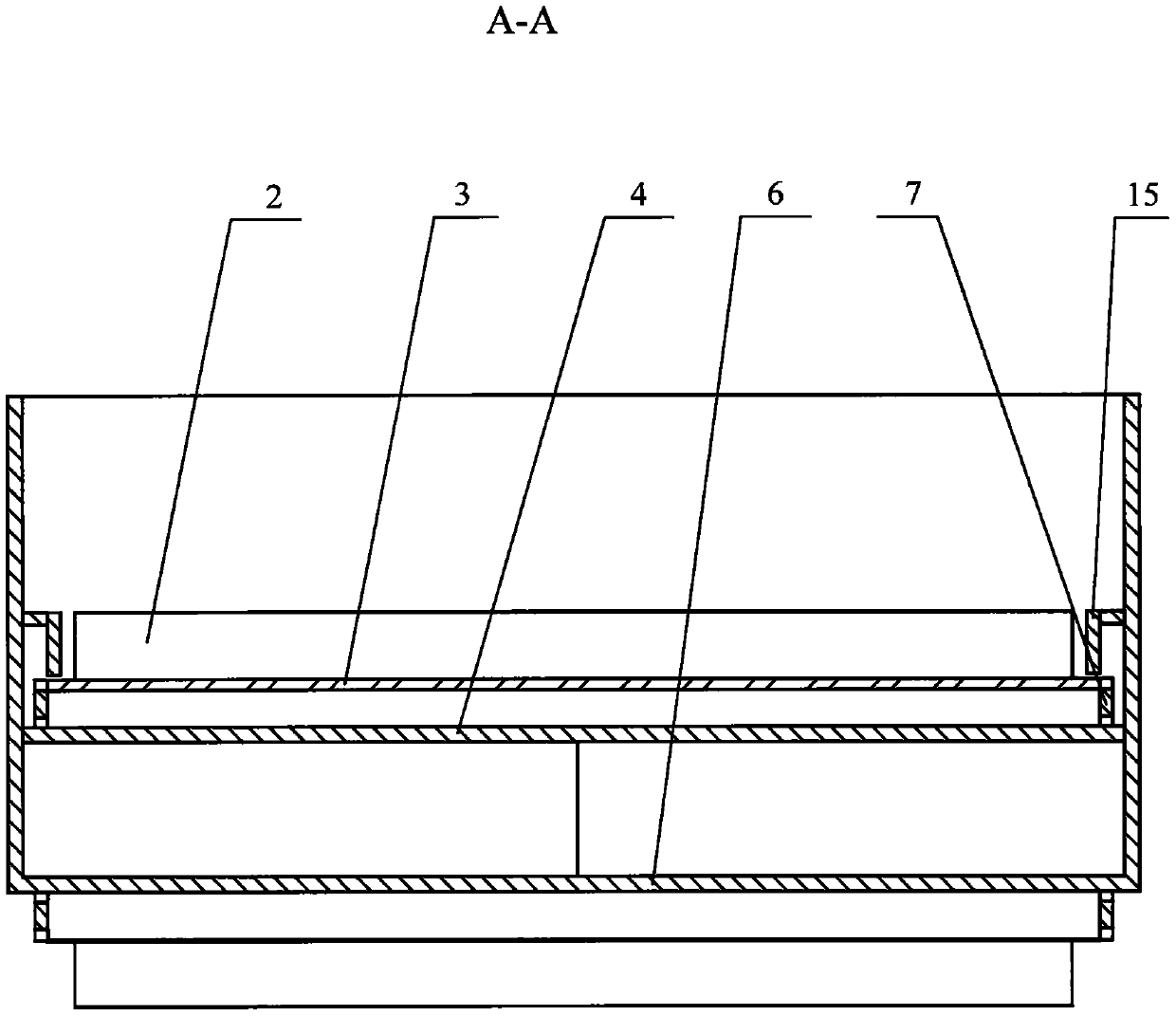

[0011] A method and equipment for continuously rinsing chemically activated carbon according to the present invention perform the rinsing operation in this way: inject water into the rinsing water tank, and directly pass the chemically activated carbon through the feeding pipe (1) continuously from the outlet of the activation furnace while it is hot. Add it to the conveying chain plate (3), start the sprocket drive motor to make the conveying chain plate run, and the activated carbon on the chain plate will slowly soak into the water. Because the chain plate runs slowly, the activated carbon will soak in the water for an appropriate time. Pyrophosphate H in activated charcoal 4 P 2 o 7 and HPO metaphosphate 3 Converted into phosphoric acid solution for recycling, when the rinsing equipment runs for a certain period of time, when the phosphoric acid concentration of the rinsing solution reaches an appropriate value, the recovered phosphoric acid solution in the rinsing tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com