Organic waste gas biological purification system and method

A biological purification and organic waste gas technology, applied in the direction of air quality improvement, chemical instruments and methods, combined devices, etc., can solve the problems of affecting the purification effect, large biological purification load, and high overall cost, so as to improve regeneration speed and activity, The effect of reducing biological purification load and reducing investment and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

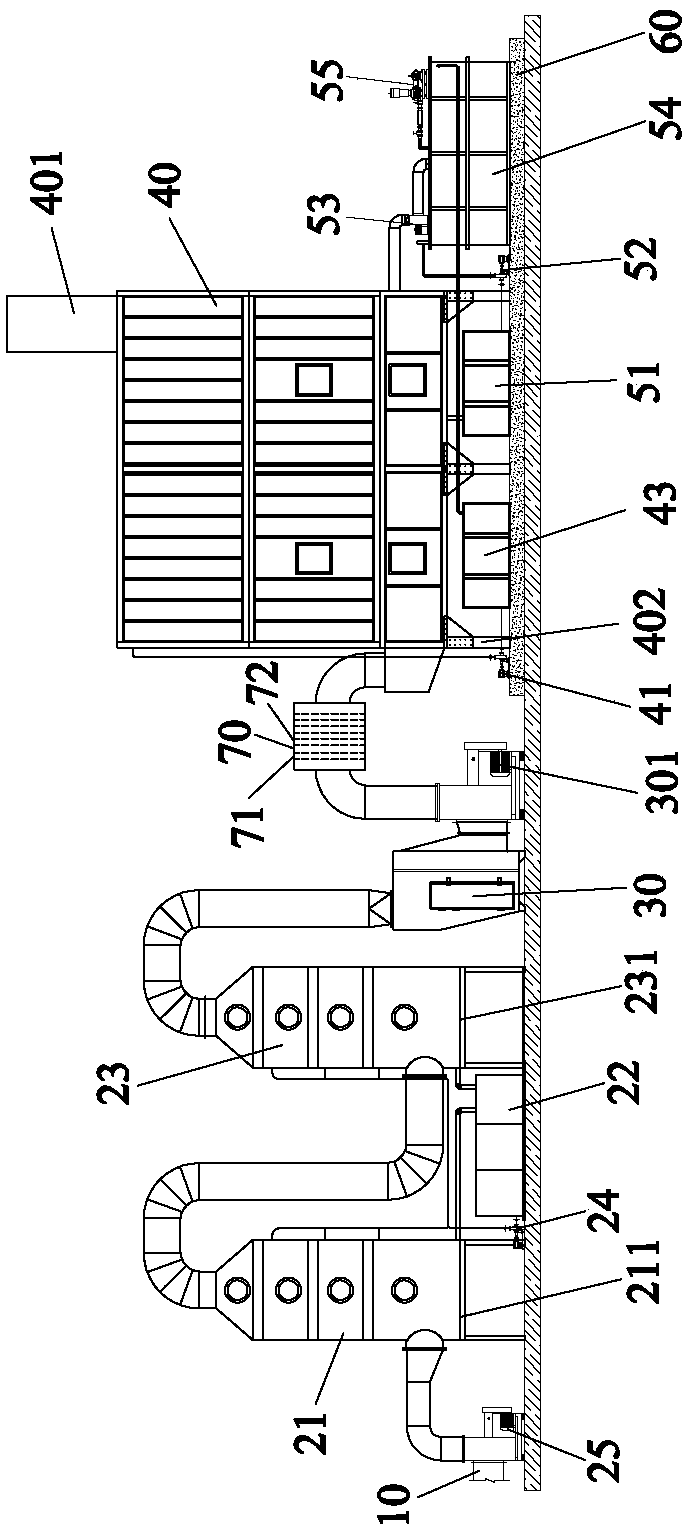

[0042] Such as figure 1 As shown, an organic waste gas biological purification system includes an air inlet pipe 10, a dust treatment device, a dry filter 30, a microbial packing filter tower 40, a biological liquid spray pump 41, a first spray device 42, and a biofilm tank transfer pool 43 and a biofilm pool culture unit, wherein:

[0043] The dust treatment device includes a swirl spray purification tower 21, a slag separation tank 22, a packing spray purification tower 23 and a circulating water pump 24. The aforementioned air intake pipe 10 is connected to the swirl spray purification tower 21. In this embodiment, the The air inlet pipe 10 is connected to the swirl spray purification tower 21 through the first centrifugal fan 25 .

[0044] The swirl spray purification tower 21 is connected to the packing spray purification tower 23, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com