Leakage-free coaling and coke pushing combined smoke purifying and recycling system and technology for coke oven

A non-leakage, coke oven technology, applied in coke ovens, coke oven heating, petroleum industry, etc., can solve the problem of not completely solving the sealing problem of coal charging flue gas, not proposing a solution for machine side burner smoke, and not having raw gas Recycling and other issues can reduce the purification load and the requirements for the material of the bag, solve the problem of smoke and dust leakage, and reduce the effect of equipment capacity and load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

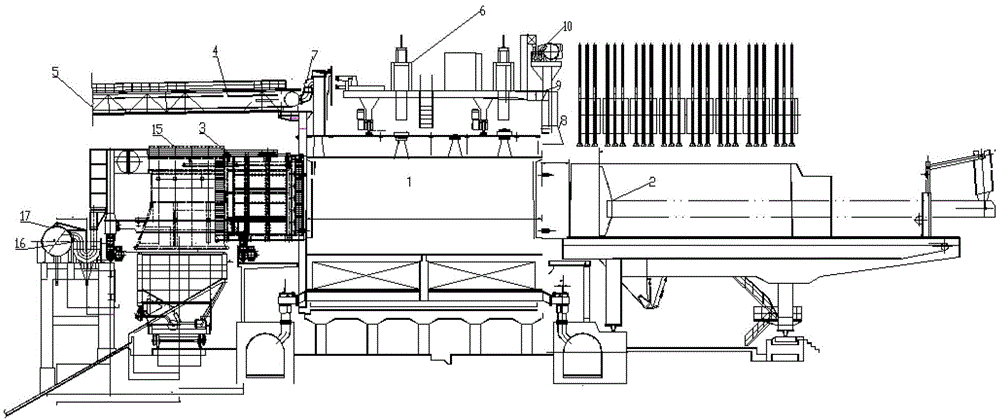

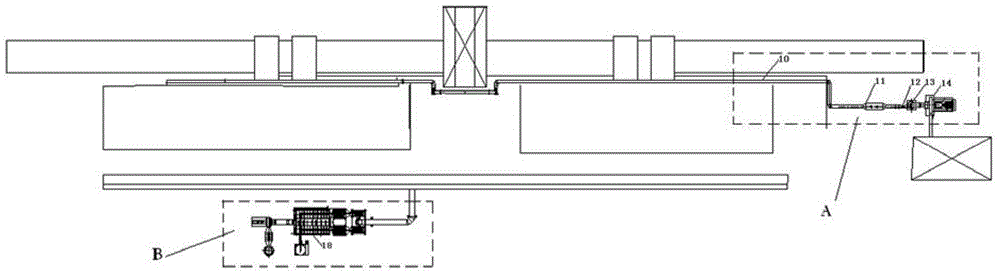

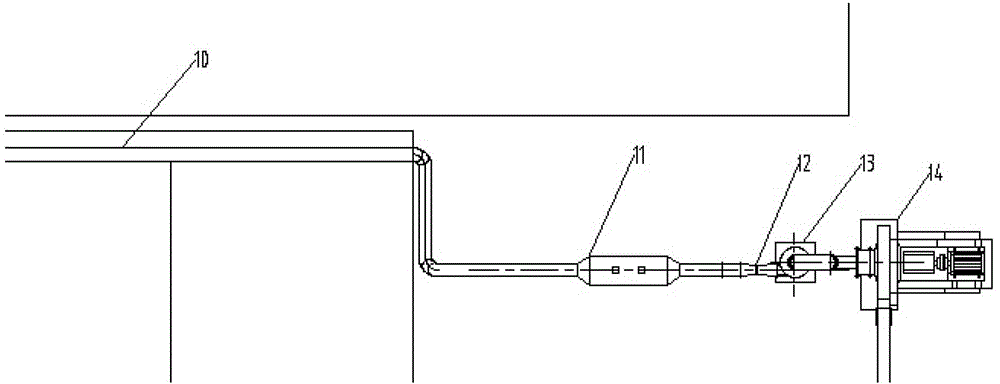

[0025] Such as figure 1 As shown, the coke oven charging coke pushing coke non-leakage purification and recovery smoke treatment system of the present invention includes a coke oven 1, a coke pushing device 2, and a coke blocking car 3, and the coke oven 1 leads to the furnace roof of the chemical production recovery purification system 5 The gas collection pipeline 4 is connected with a double U-shaped water-sealed smoke guiding vehicle 6 and a high-pressure ammonia water system 7, and a dust collection cover 8 is installed on the burner side of the coke oven 1, and the smoke collection cover 8 is installed on the double U-shaped water The leak-free sealing connection device 9 on the sealed smoke guiding vehicle 6 is connected with the U-shaped water-sealed dust removal dry pipe 10 . Such as figure 2 , image 3 , Figure 4As shown, behind the U-shaped water-sealed dust-removing dry pipe 10, an automatic ignition incineration device 11, a Venturi dust removal device 12, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com