Wet type dual-collecting and fume purifying apparatus

A technology of flue gas purification and wet dust removal, which is applied in chemical instruments and methods, separation of dispersed particles, and the use of liquid separation agents, etc. It can solve the problems of not being too high in wind speed, lowering the bottom purification efficiency, and carrying water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

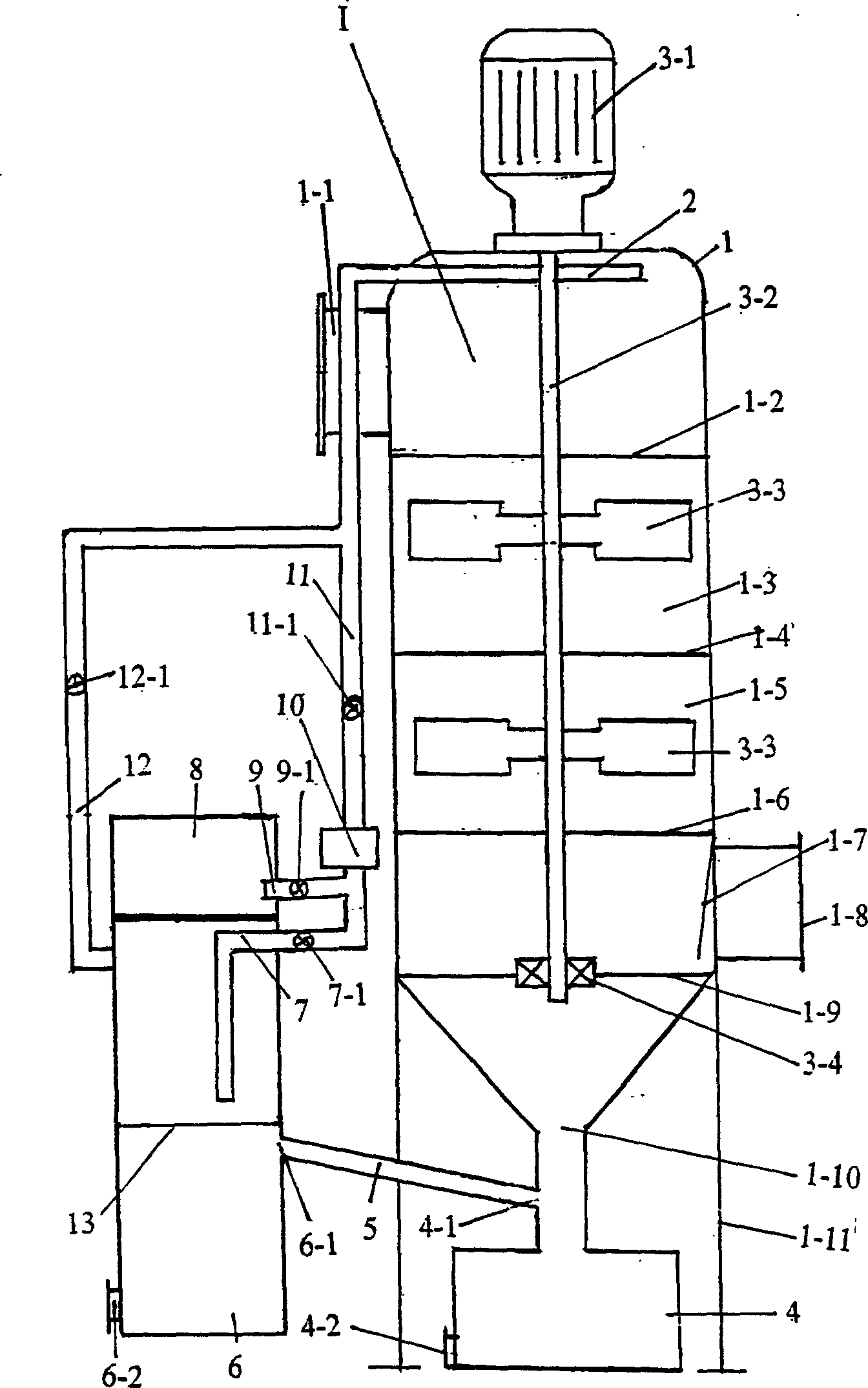

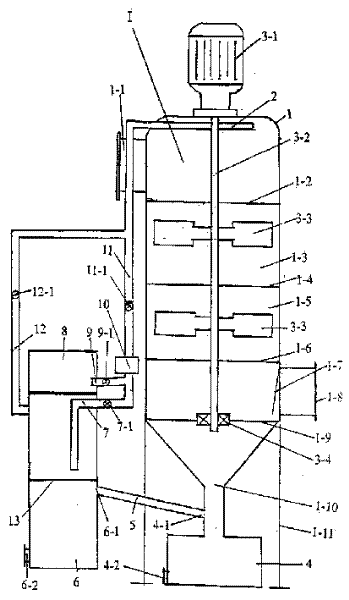

[0019] Example 1 has a foam purifier I, which is fixed by support brackets 1-9. The inlet and outlet ports 1-1 and 1-8 of the foam purifier 1 are respectively arranged on the upper and lower parts of the cylinder body 1, and the dust outlet 1-10 is arranged at the bottom of the cylinder body. The smoke inlet 1-1, that is, the upper part is provided with a sprayer 2, the nozzle of the sprayer 2 is directed downward, and the lower part of the sprayer 2 is provided with upper and lower mesh plates 1-2, 1-6, upper and lower mesh plates 1-2, The distance between 1-6 depends on the amount of exhaust gas and the dust concentration, which can reach 2 to 3 meters. The space between the two mesh panels 1-2 and 1-6 is the foam chamber. The middle screen plate 1-4 is arranged between the lower screen plates 1-2 and 1-6. The upper, middle and lower screen plates divide the interior of the purification cylinder 1 into 4 chambers. The two middle chambers 1-3 and 1-5 are: In the foam chamber...

Embodiment 2

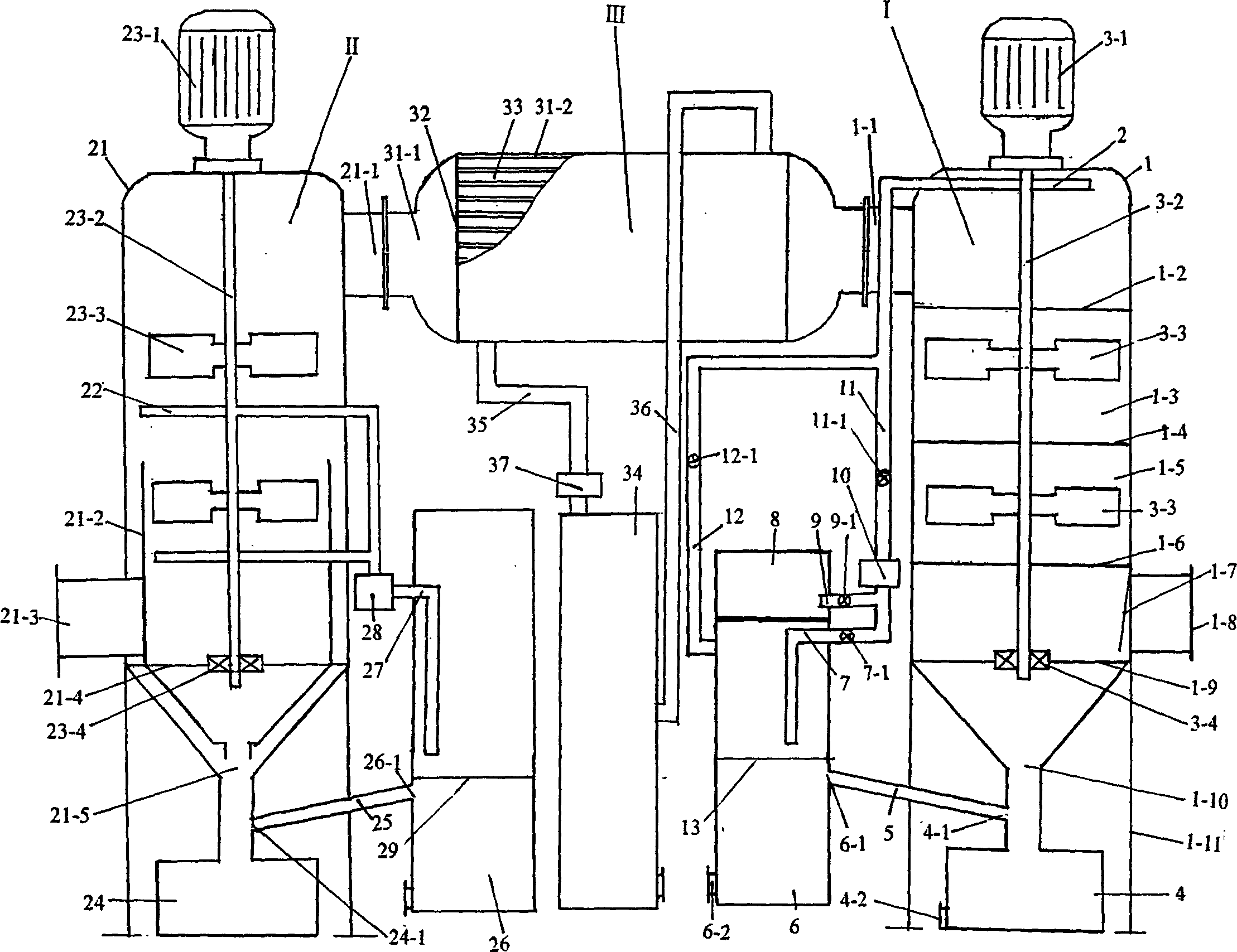

[0023]Example 2 has a spray centrifugal scrubber II, a foam cleaner I and a cooler III, and the foam cleaner I is the same as Example 1. The scrubber is fixed by the support frame. The inlet and outlet ports 21-3 and 21-1 of the scrubber are respectively arranged on the lower and upper parts of the cylinder body 21. The lower part of the cylinder body 21 has an inner cylinder 21-2 and a slag outlet. 21-5 is arranged at the bottom of the cylinder 21, the slag outlet 21-5 is connected to the slag collecting box 24, the dust removal cylinder 21 is provided with a sprayer 22 and a rotating shaft 23-2, the nozzle of the sprayer 22 is upward, and the rotating shaft 23-2 is connected with the place. The main shaft of the motor 23-1 on the top of the cylinder body 21 is connected, and the end of the rotating shaft 23-2 is connected with a bearing 23-4, which is installed in the bearing support 21-4 connected with the dust removal cylinder 21-1. The rotating shaft 23-2 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com