Multiple pump arrangement

A technology of eccentric screw pump, casing, applied in the direction of pump, pump element, pump control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

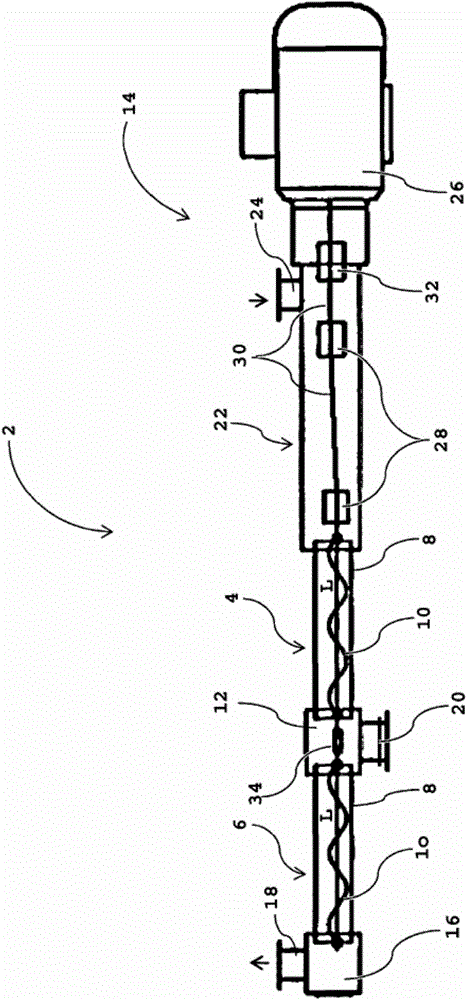

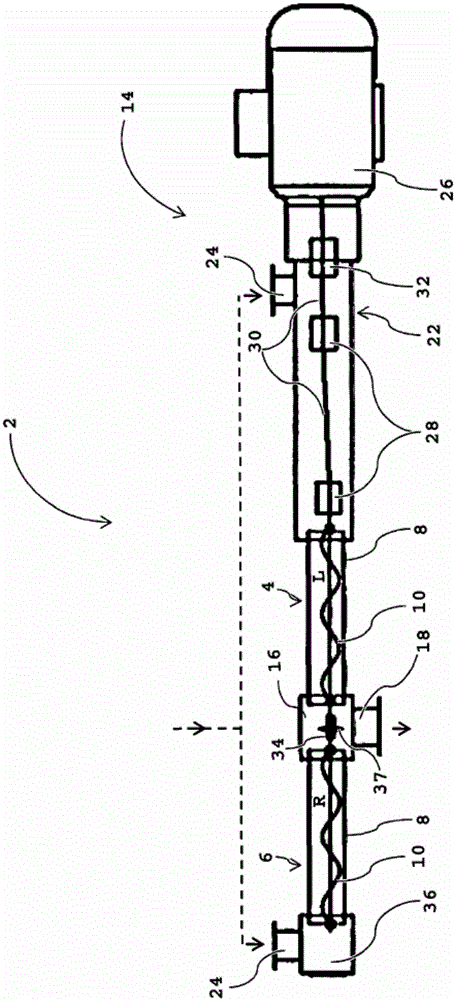

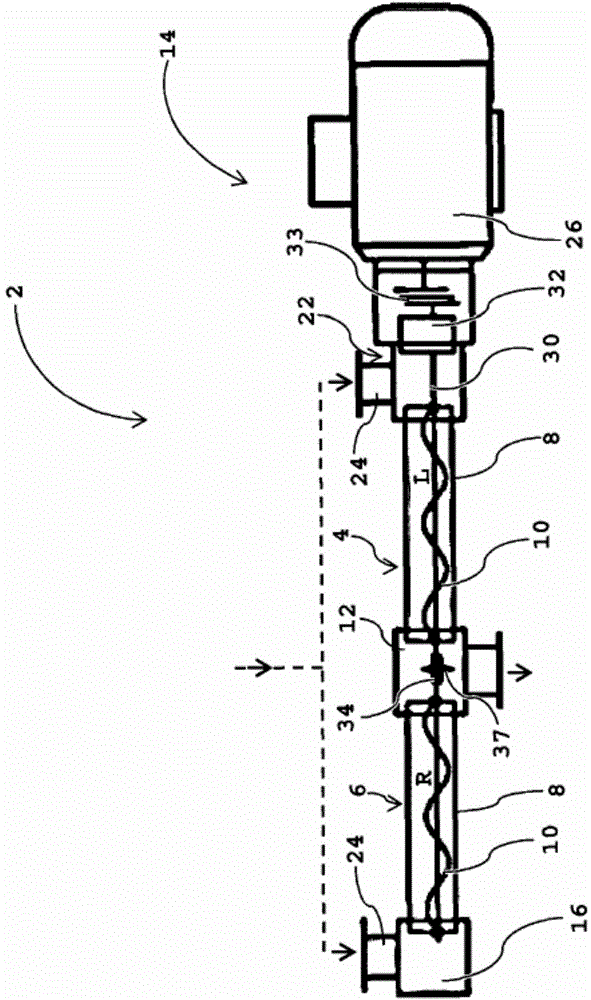

[0041] according to figure 1 The device shows an eccentric screw pump 2 with a first delivery module 4 and a second delivery module 6 each comprising a stator 8 and a rotor 10, the first delivery module and the second delivery module passing through the flow housing 12 interconnected. On the end of the eccentric screw pump 2 opposite the drive mechanism 14 , a pressure housing 16 with a pressure connection 18 is arranged on the second delivery module 6 . The two delivery modules 4 , 6 are structurally identical and have a left-handed pitch L. The flow-through housing 12 is a pressure housing or a suction housing provided with a closure means 20 . The closure means 20 should be arranged in the vicinity of the pressure housing in order to avoid dead spaces which would adversely affect the flow course and thus interrupt the conveyed medium.

[0042] The eccentric screw pump 2 is equipped with support feet, not shown here. The non-conveying pipe connections of the flow housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com