Classification device, standing pulverizer using the classification device, and coal burning boiler apparatus

一种分级装置、立式的技术,应用在固体分离、化学仪器和方法、用气流将固体从固体中分离出来等方向,能够解决粉碎动力增加、粉碎量降低、粉碎机粉碎部拥有煤量增加等问题

Active Publication Date: 2013-03-20

MITSUBISHI POWER LTD

View PDF1 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, fine powder is bitten into the press roller, which causes the self-excited vibration of the roller, and the amount of coal held in the pulverizing part of the pulverizer increases, resulting in a reduction in the pulverization amount and an increase in the pulverization power.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

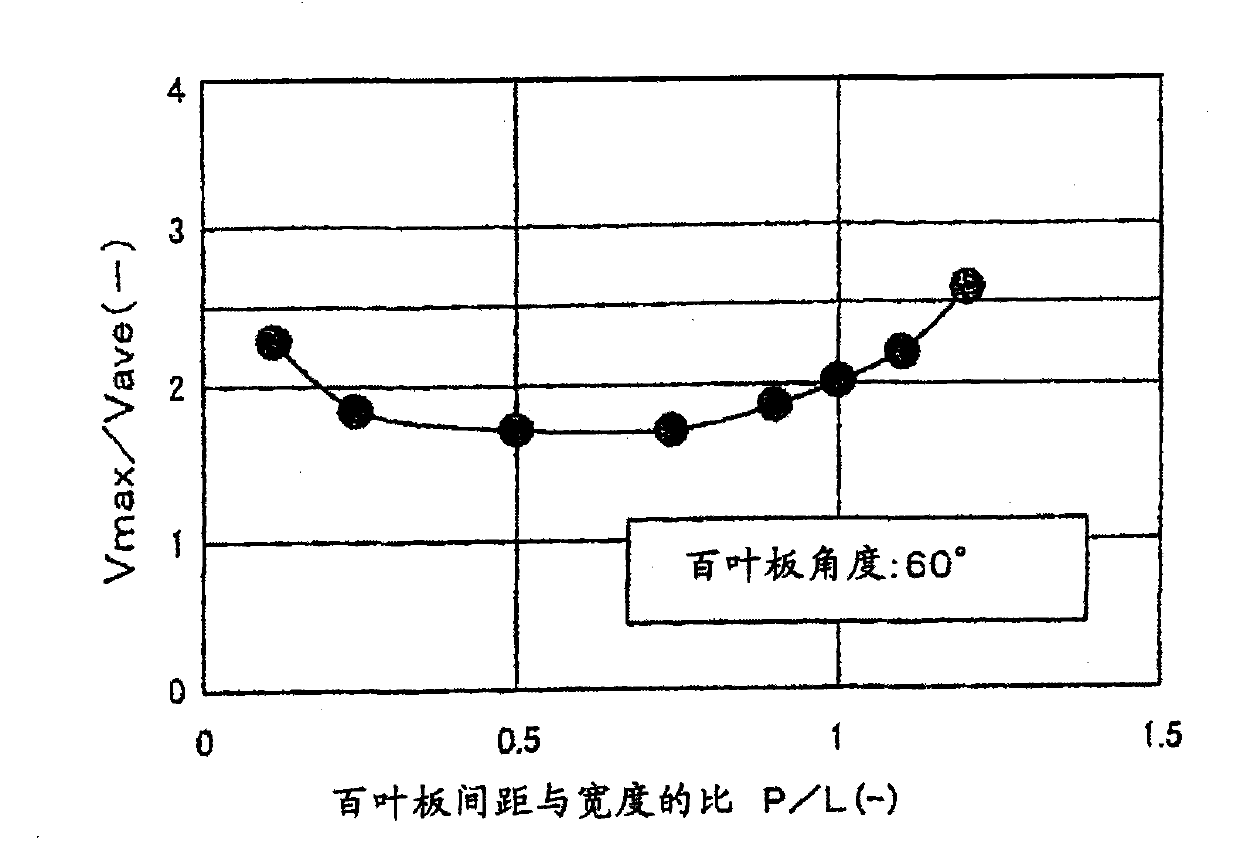

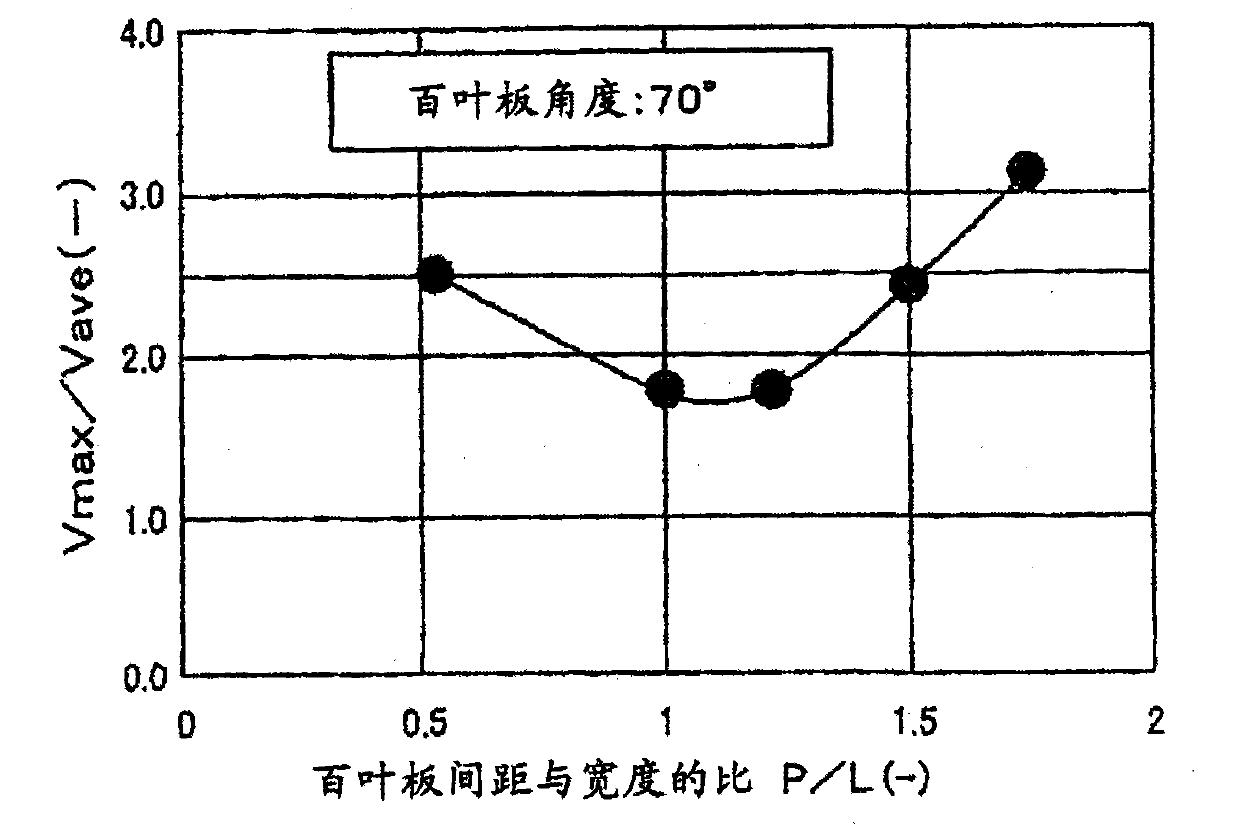

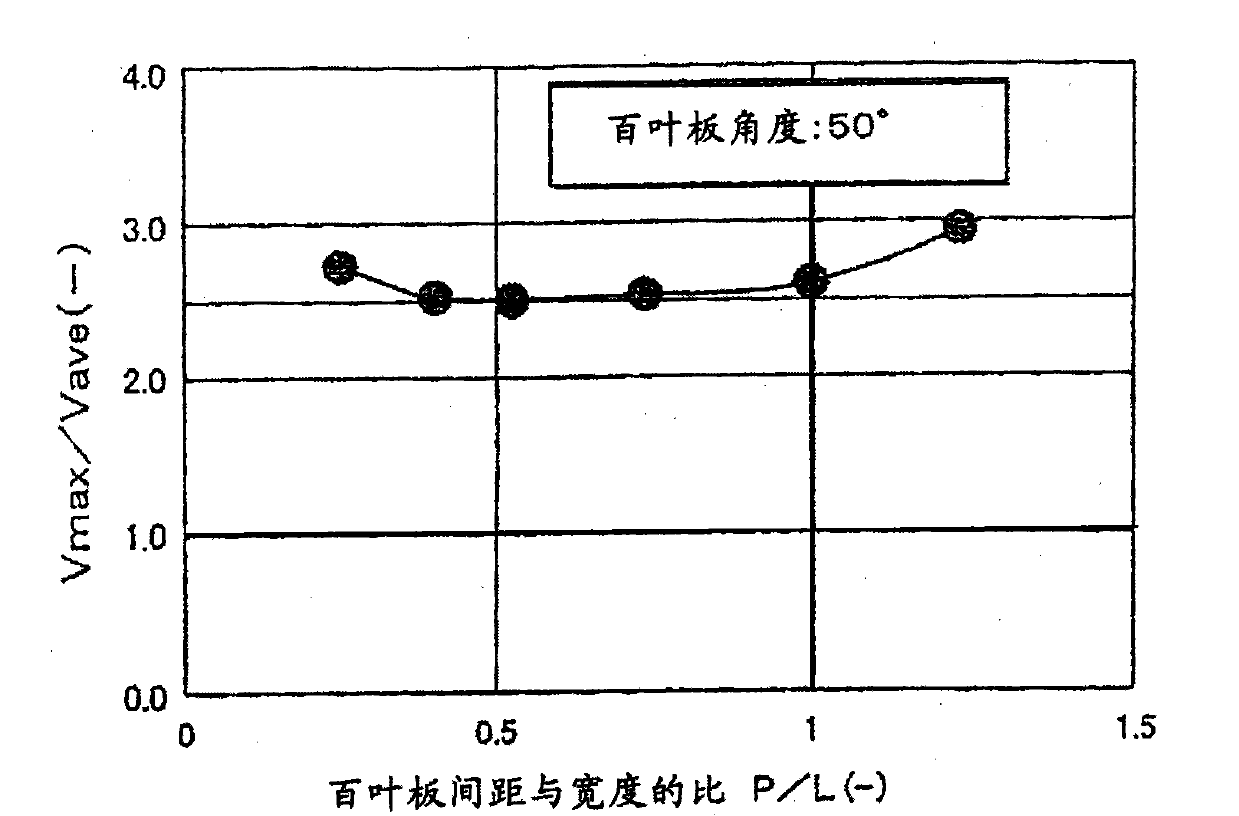

[Problem] To provide a classification device in which product fine powder little in mixture ratio of coarse particles can be obtained. [Means for Resolution] A classification device characterized in that a setting pitch P between stationary fins 13 and a width L of each stationary fin 13 are combined so that a value of P / L is in a range between 0.042×(¸-50)+0.64 and 0.019×(¸-50)+0.22 in 50°‰¤6‰¤70° when ¸ is an inclination angle of each stationary fin 13, P is the setting pitch, and L is the width in a direction of circulation of particles.

Description

technical field The invention relates to a classifying device for separating particles in a gas-solid two-phase flow into coarse particles and fine particles, in particular to a classifying device suitable for being assembled on a vertical pulverizing device of a coal-burning boiler device and the like. Background technique In a coal-fired boiler plant for thermal power generation that burns pulverized coal as fuel, a vertical roller mill is used as a fuel supply device. Fig. 27 shows a conventional example thereof. This vertical roller pulverizer includes: a pulverizing part 5 for pulverizing coal as a raw material of pulverized coal by the bite of pulverizing table 2 and pulverizing roller 3; Classification section 6 of arbitrary particle size. The operation of this vertical roller mill will be described as follows. After the coal supplied from the coal supply pipe (raw material supply pipe) 1, that is, the object to be pulverized 50 falls to the center of the rotating...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B07B7/083B02C15/04B07B7/08

CPCB07B7/083B02C15/04B02C2015/002

Inventor 大谷义则金本浩明野村伸一郎三井秀雄竹野丰

Owner MITSUBISHI POWER LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com