Improved low heat rejection high efficiency engine system

An engine, internal combustion engine technology, applied in engine components, combustion engines, machines/engines, etc., to solve problems such as increased compression workload, reduced gas/fuel mixing efficiency, and high temperature and pressure

Inactive Publication Date: 2010-08-18

ROTEC DESIGN

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Increased gas density at higher temperatures and pressures due to shorter ignition delay (due to higher gas temperatures) resulting in less efficient gas / fuel mixing;

Increased compression work required due to the higher temperature and pressure of the inhaled charge gas

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

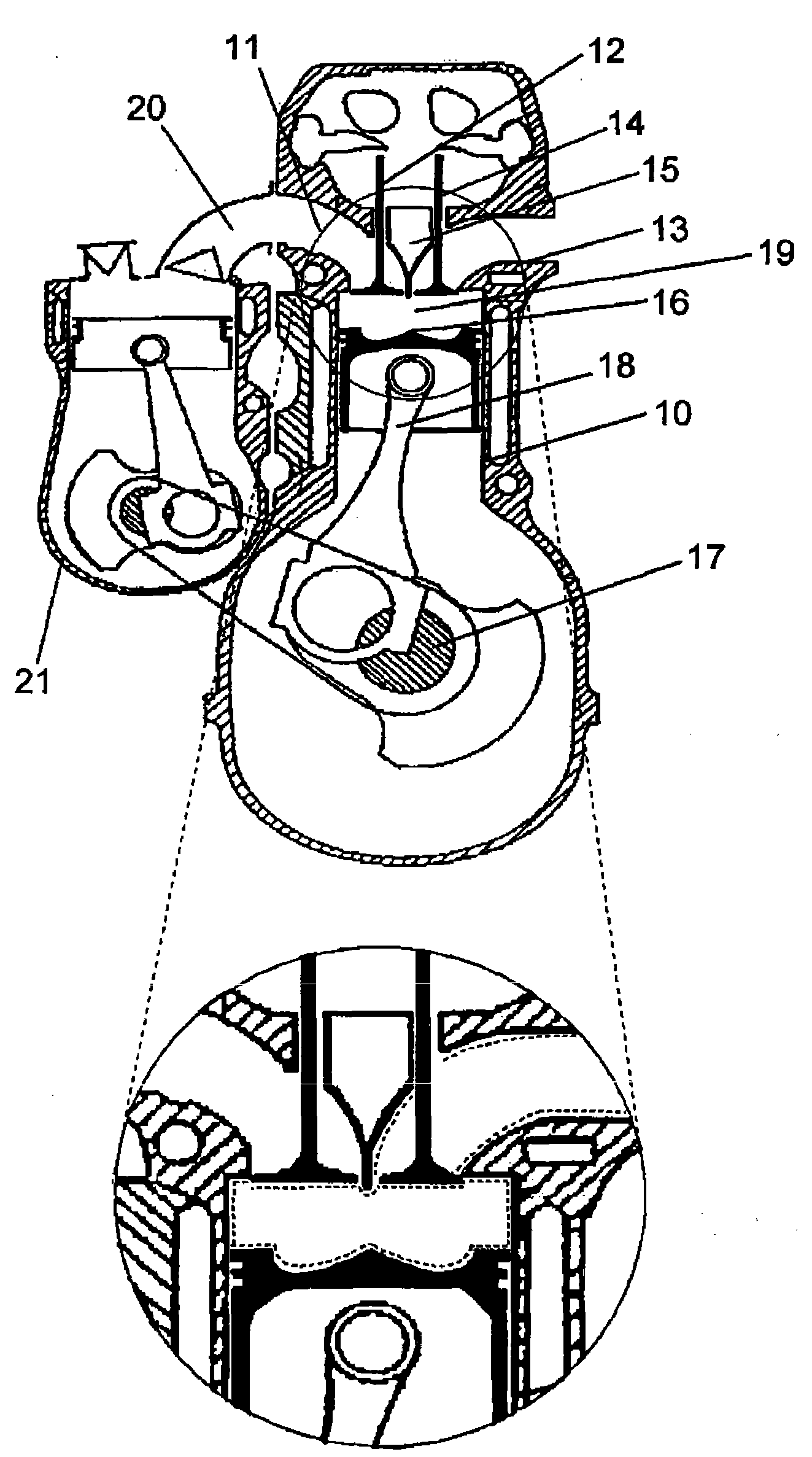

An improved low heat rejection high efficiency engine system for an insulated two stroke internal combustion engine which includes an insulation component provided in association with at least one combustion chamber in order to minimise heat loss during operation, the system having at least one inlet port fluidly connected to a transfer port from a pumping cylinder for inlet of a fresh charge in an induction portion of the operation cycle, the inlet port opened and closed during the operation cycle by an inlet valve, characterized in that the period for which the inlet valve is open during the operation cycle is less than 180 DEG of rotation.

Description

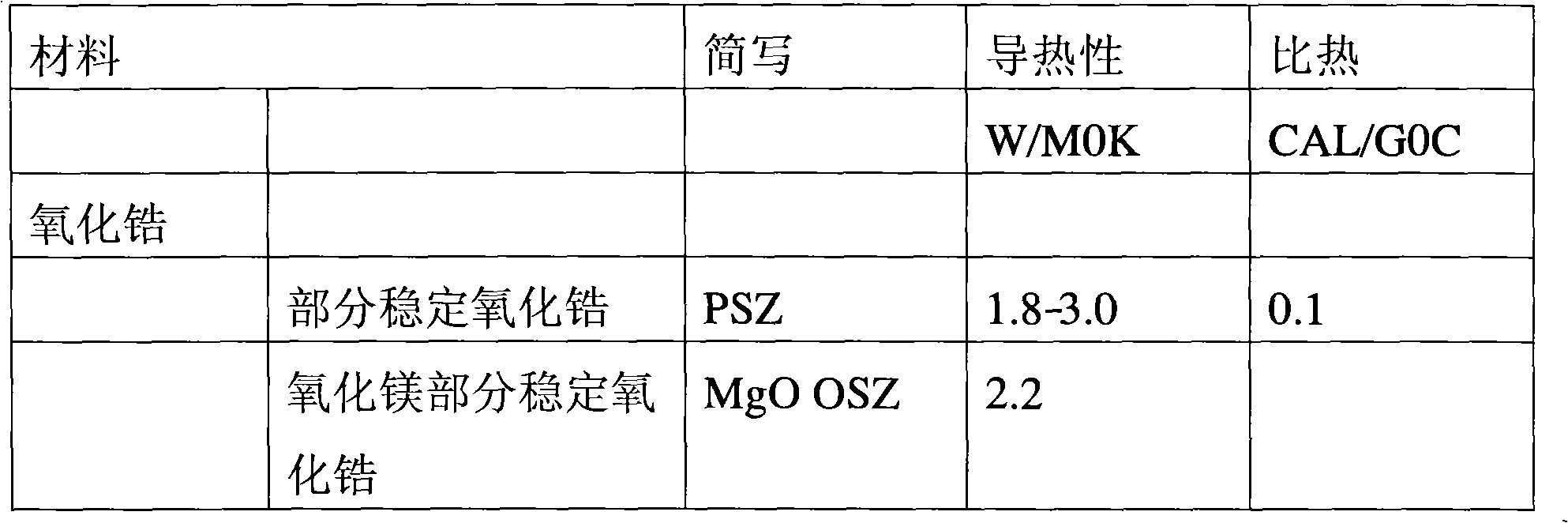

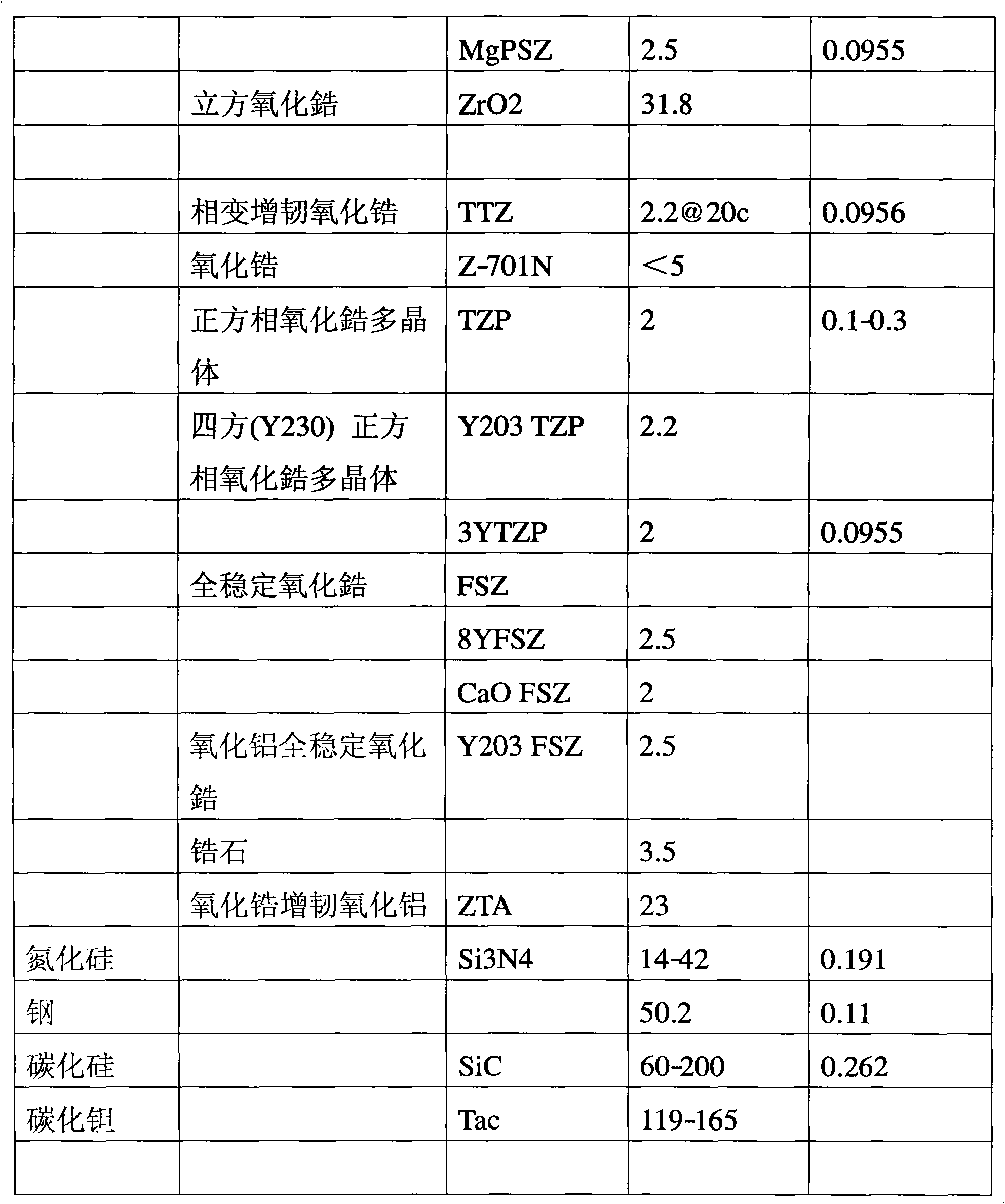

technical field The invention relates to the field of improving the efficiency of engines and drive trains for vehicles, especially low heat loss engines and drive trains. Background technique The inventors of the present invention have been active in the field of engine systems, especially in the technology of improving engine efficiency, for example, US Pat. Nos. US6,571,755 and US5,265,564. The relevant engines in the present invention refer to the engines described in these two patents. The application of thermal insulation of surfaces exposed to hot process gases, including coatings, air gaps, gaskets or the use of low heat transfer materials on components, can improve thermal efficiency of operation, as is well known in the art of internal combustion engines. But in practice, as shown in the prior art, such measures improve operational efficiency far less than expected or extrapolated values. Except for smaller (eg lawn mowers and scooters) and larger (eg cargo sh...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F02B33/22F02B33/06F02B33/00F02B69/06F02B77/11

CPCF02B77/11F02B69/06F02B33/22Y02T10/16F02B33/06

Inventor 罗伯特·M·拉瑟弗德保罗·F·邓恩

Owner ROTEC DESIGN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com