Medicinal scraping trimmer

A trimmer and fork-shaped seat technology, applied in medical science, surgical cutting instruments, metal processing, etc., can solve problems such as roughness, uneven nose mold surface, and difficulty in cutting with a scalpel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

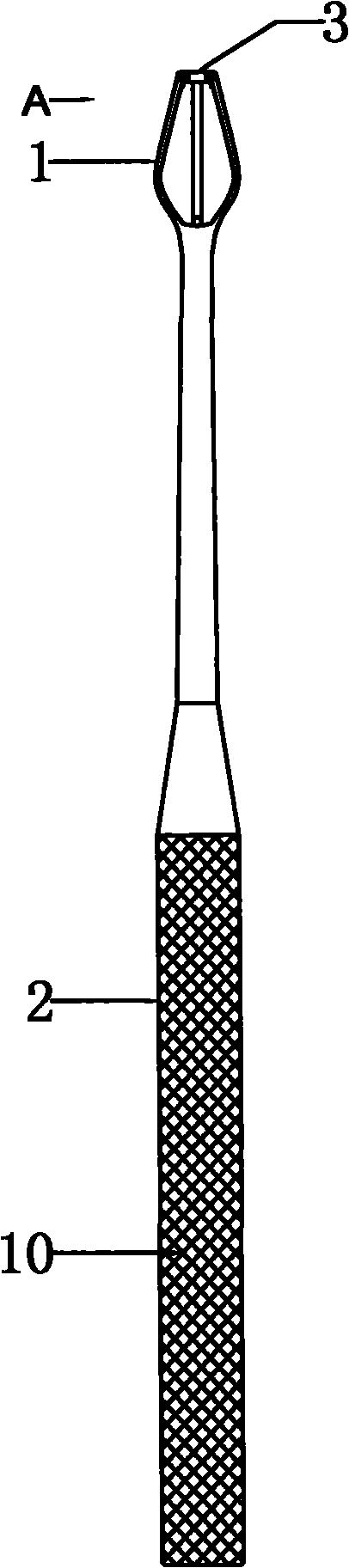

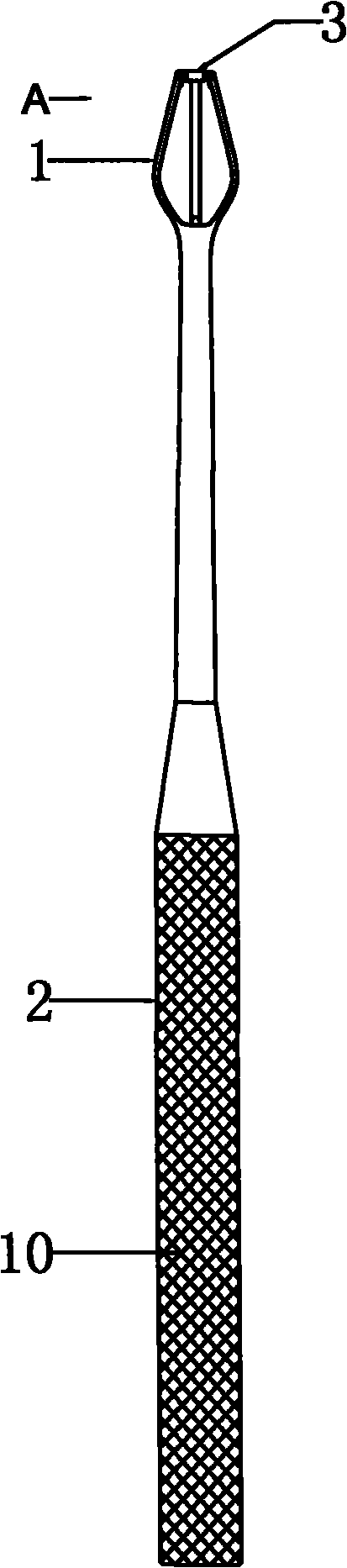

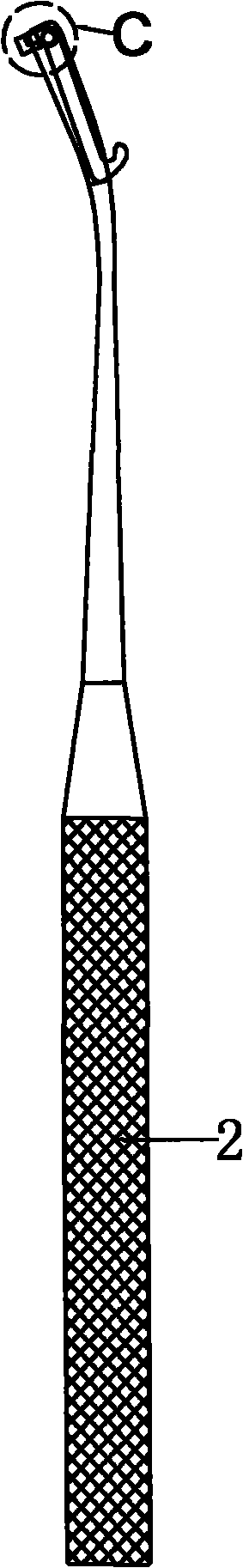

[0027] The present invention will be further described below in conjunction with accompanying drawing 1 to accompanying drawing 14, and the preferred embodiment of the present invention is: the medical scraping trimmer described in the present embodiment includes handle 2, tool rest 3, and handle 2 tail portion is thick, front The part is slender, and the tail of the handle 2 is provided with anti-slip lines 10 to prevent the medical scraper trimmer from sliding or falling off during operation. , the width of the fork head of the fork seat 1 is smaller than the width of the fork tail, the fork head of the fork seat 1 is provided with a mounting hole 5, and the tool rest 3 is installed on the fork seat 1 through the rotating shaft 4. In the hole 5, the lower end of the knife rest 3 is provided with a blade groove 6, and the blade 11 is installed in the blade groove 6. The blade 11 installed on the fork seat 1 is an obtuse angle V shape, and the blade 11 installed on the U-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com