Filter device for resin emery wheel grinding liquid

A filter device and resin grinding wheel technology, applied in the direction of filtration separation, gravity filter, loose filter material filter, etc., can solve the problem of unsatisfactory non-woven filter effect, space influence on the overall coordination of the workshop, grinding liquid and non-woven fabric Waste and other problems, to achieve the effect of convenient operation, labor saving, and reduction of non-production necessary consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

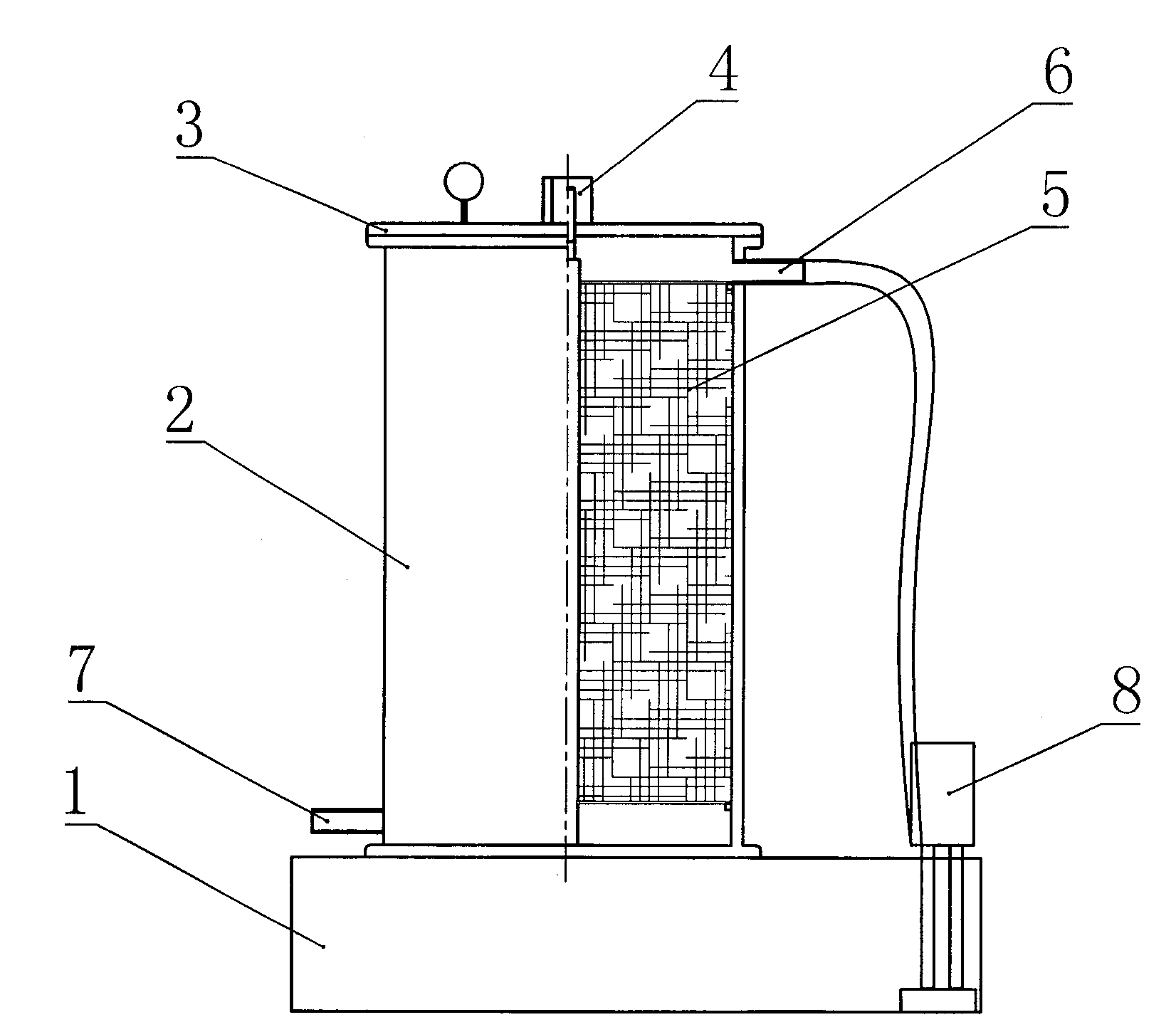

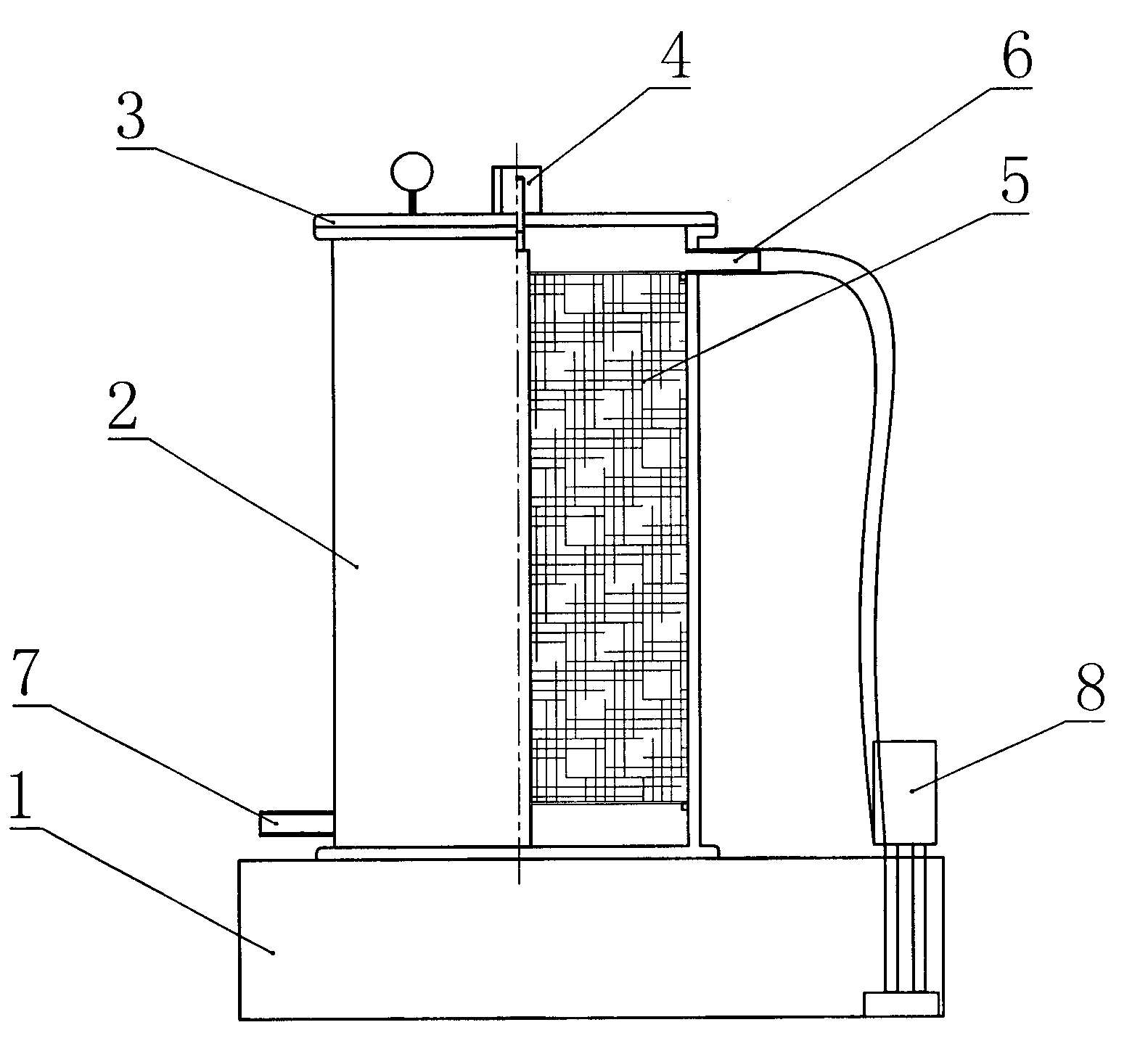

[0007] As shown in the drawings, the present invention includes a liquid storage tank 1, a filter box body 2, a filter cover plate 3, a lock nut 4,

[0008] The top of the above-mentioned liquid storage tank 1 is provided with a filter box body 2, and a support shaft passing through the box body is arranged inside the filter box body 2, and the filter cover plate 3 is fixed with the support shaft by a lock nut 4 to realize the connection with the filter box. The connection to body 2 is sealed. The filter box 2 is filled with crushed sponge 5 for filtering impurities, and has a liquid inlet 6 and a liquid outlet 7 on the top and bottom of the box respectively, and an oil pump 8 is arranged in the liquid storage tank 1, and the oil pump 8 passes through The oil pipe communicates with the liquid inlet 6.

[0009] During use, the grinding liquid in the liquid storage tank 1 is sucked into the filter housing 2 through the oil pump 8, the impurities in the grinding liquid are absor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com