Method for obtaining molding resilience value of plate based on CAE (Computer Aided Engineering) analysis method

A sheet metal forming and springback technology, which is applied in the field of accurate springback measurement in the forming and processing of automobile panel parts, can solve the problems of prolonging the production cycle, increasing the cost of mold making and high cost, accelerating the production and improving the one-time success. efficiency and cost savings

Inactive Publication Date: 2010-08-25

JIANGSU KAMING MOLD

View PDF6 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When manufacturing molds, it is difficult to accurately produce molds that meet the design requirements, and the cost of large-scale forming molds is very high. Making molds based on experience and repeated rework will increase the production cost of molds and prolong the production cycle.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

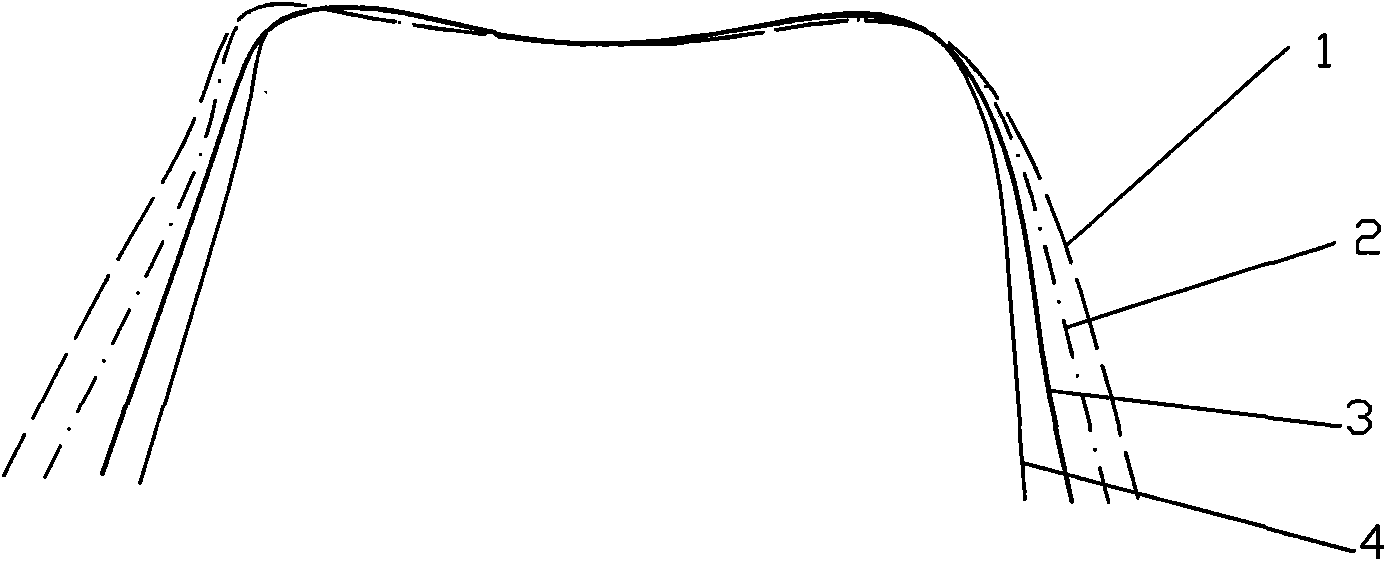

The invention relates to a method for obtaining the molding resilience value of a plate based on a CAE (Computer Aided Engineering) analysis method, relating to a method for accurately obtaining the resilience value in the molding machining of an automobile covering piece. The method comprises the following steps of: firstly, determining the design data for the molding machining; secondly, obtaining the molding analogue resilience value of the plate through the CAE analysis method; thirdly, manufacturing a test mould according to the design data for the molding machining, and molding and machining the plate through the test mould to manufacture a test molding piece; fourthly, selecting a plurality of measuring points on the test molding piece, and measuring the outline data of the test molding piece to obtain the actual resilience value of a certain measuring point; fifthly, comparing the actual resilience value with the analogue resilience value to obtain a deviation ratio, and obtaining the set resilience value of each measuring point by taking the mean of the deviation ratio as a resilience compensating factor and according to the analogue resilience value and the resilience compensating factor; and finally manufacturing a formal mould according to the set resilience value of each measuring point. In the invention, the accuracy rate of manufacturing the mould is improved through data acquisition, and important data are provided for manufacturing the mould meeting the design requirement once.

Description

The Method of Obtaining Springback of Plate Forming Based on CAE Analysis Method technical field The invention relates to a method for setting the amount of springback in the forming process of curved sheet materials, in particular to a method for accurately obtaining the amount of springback in the forming process of automobile cover parts. Background technique The springback of stamping parts has always been the focus of attention in the industry, mainly because of the uncertainty of springback and it is difficult to control. Conventional springback control methods include local compression to reduce springback, one process divided into two stages of bending, inner fillet hardening method, hardening processing method, springback control method of changing the overall drawing forming into partial bending forming, and eliminating residual Stress method, stiffener frozen shape method, negative springback method, quenching, tempering suppression springback method, frozen sha...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B21D22/06

Inventor 朱于杰朱其昌薛士春杨国成朱云

Owner JIANGSU KAMING MOLD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com