Mechanism for adjusting inclination angle of main shaft of rim roll forming machine

A technology of inclination angle and adjustment mechanism, which is applied in metal rolling and other directions, can solve the problems of inconspicuous effect, and achieve the effect of reasonable low contact point of profile surface, improved service life and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

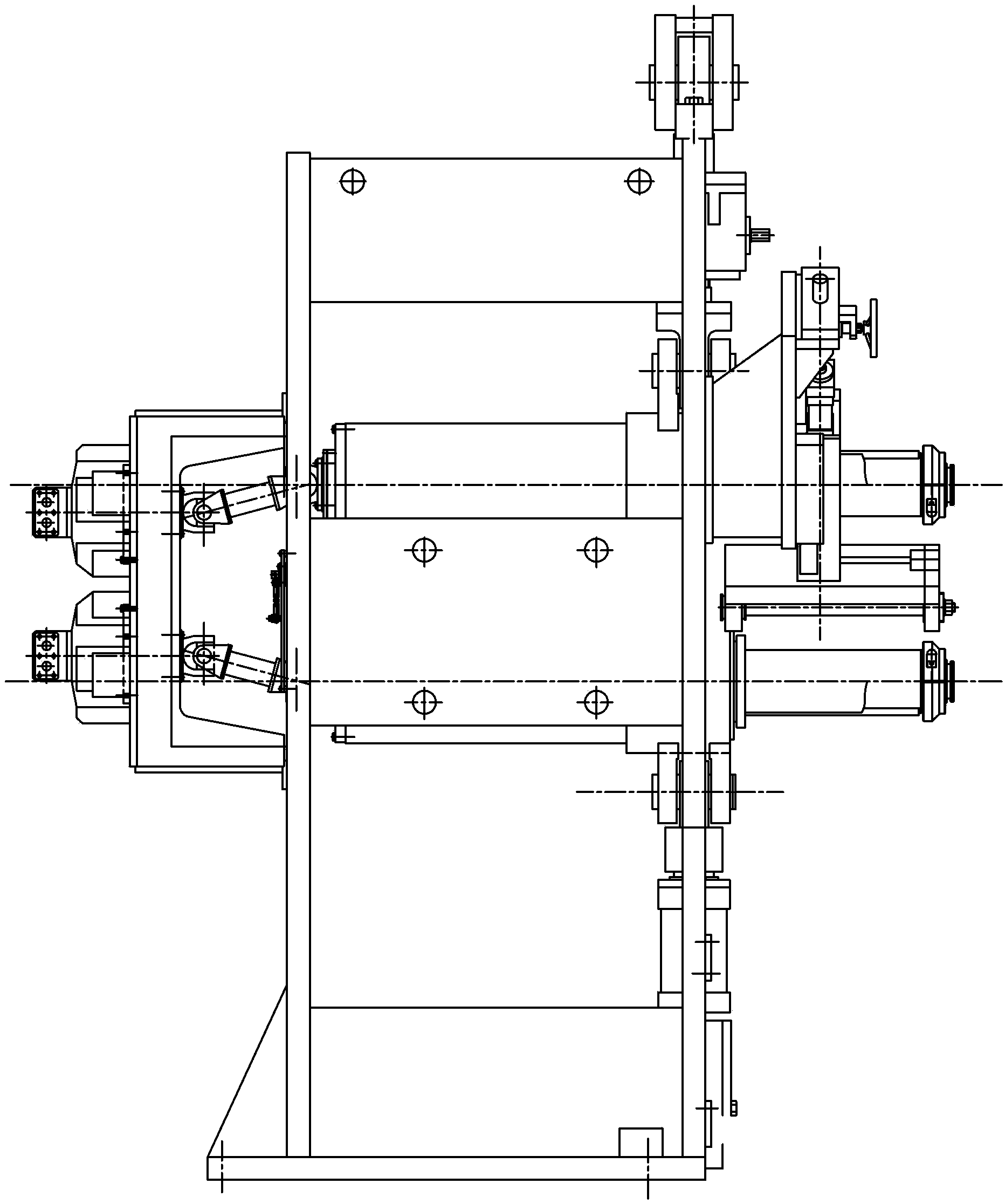

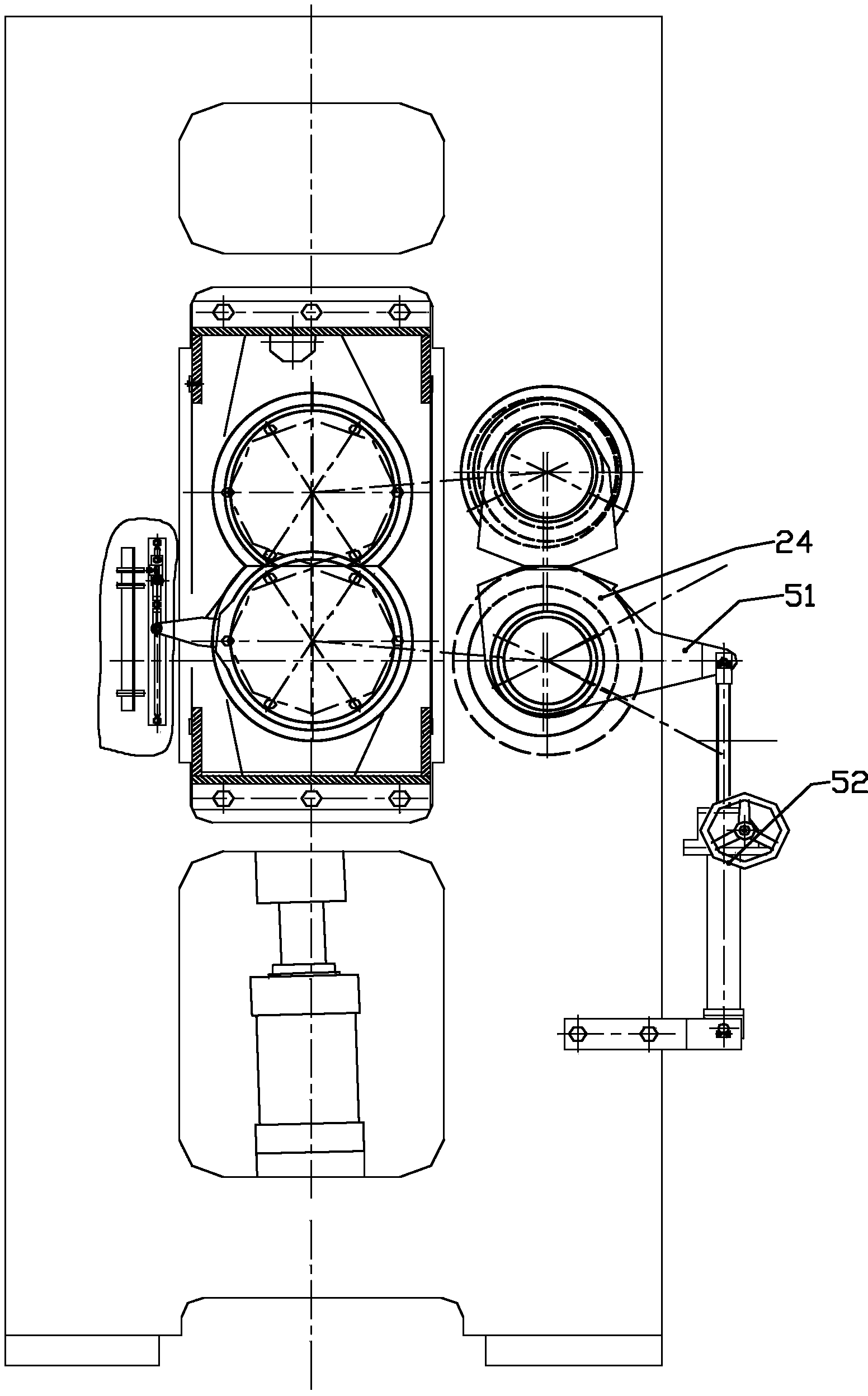

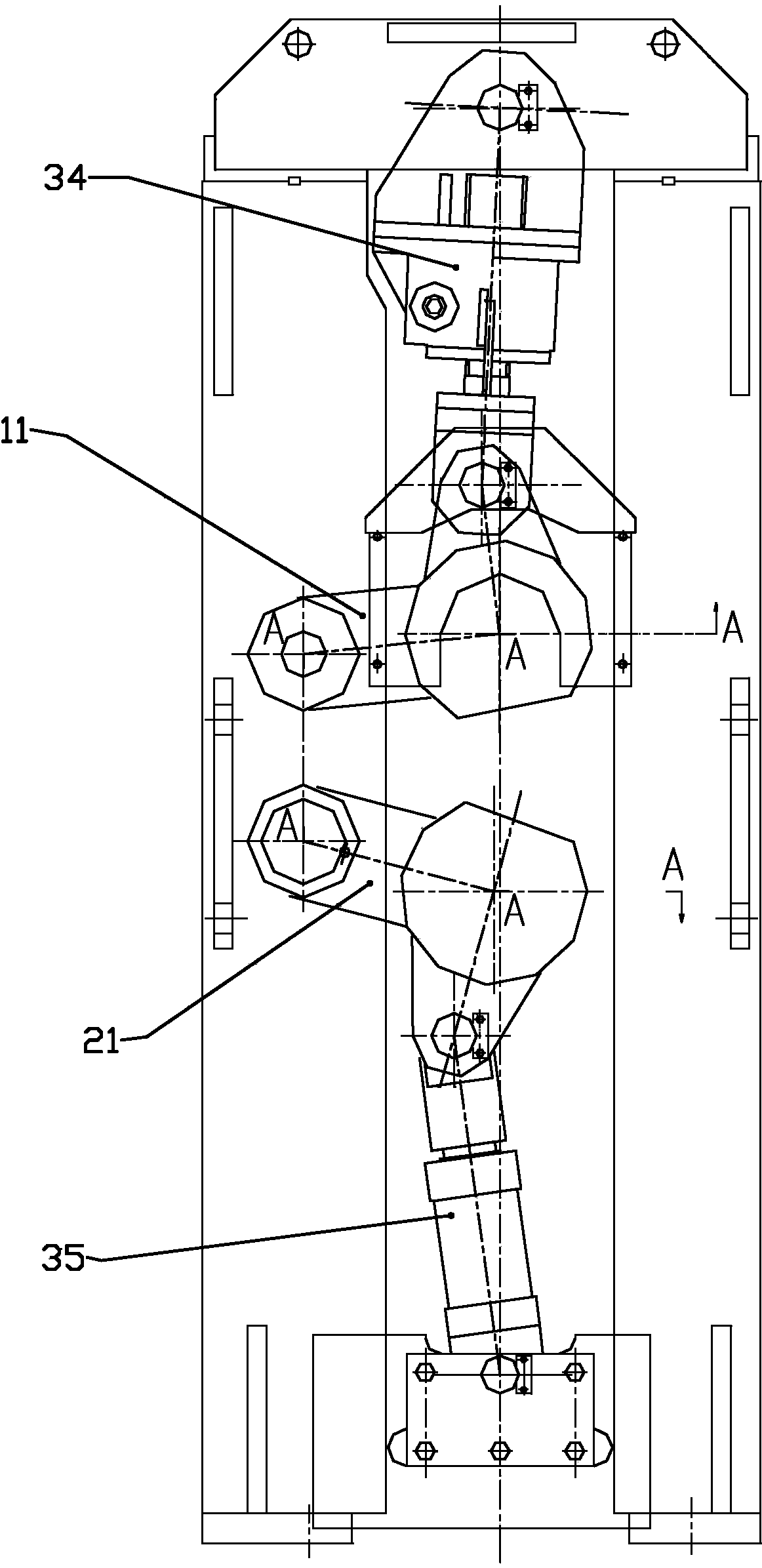

[0023] Such as Figure 1 to Figure 6 as shown,

[0024] A mechanism for adjusting the inclination angle of the main shaft of a rim rolling machine, including a machine body, an upper main shaft module and a lower main shaft module, which are described below:

[0025] The upper main shaft module includes a first eccentric block 11 , a first hinge shaft 12 , a first main shaft 13 and a first incomplete gear 14 .

[0026] The first eccentric block 11 is a cast iron, in the first eccentric block 11 machining two parallel first through holes and second through holes, the first hinge shaft through the first through hole rear front end is installed one The first joint bearing, the first joint bearing 15 is sleeved in the first cylindrical sliding sleeve, the first cylindrical sliding sleeve is sleeved in a shaft hole of the frame, and an end cover is fixed on the outer end of the first cylindrical sliding sleeve , A limit slide slot along the axial direction of the first hinge axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com