Transverse and longitudinal cutting control method and control system of plate products

A longitudinal cutting and control system technology, applied in manufacturing tools, stone processing tools, stone processing equipment, etc., can solve the problems of inaccurate adjustment, inappropriate to ensure the straight angle requirements of small plates, etc., to achieve safe and accurate control, realize automatic control, Stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

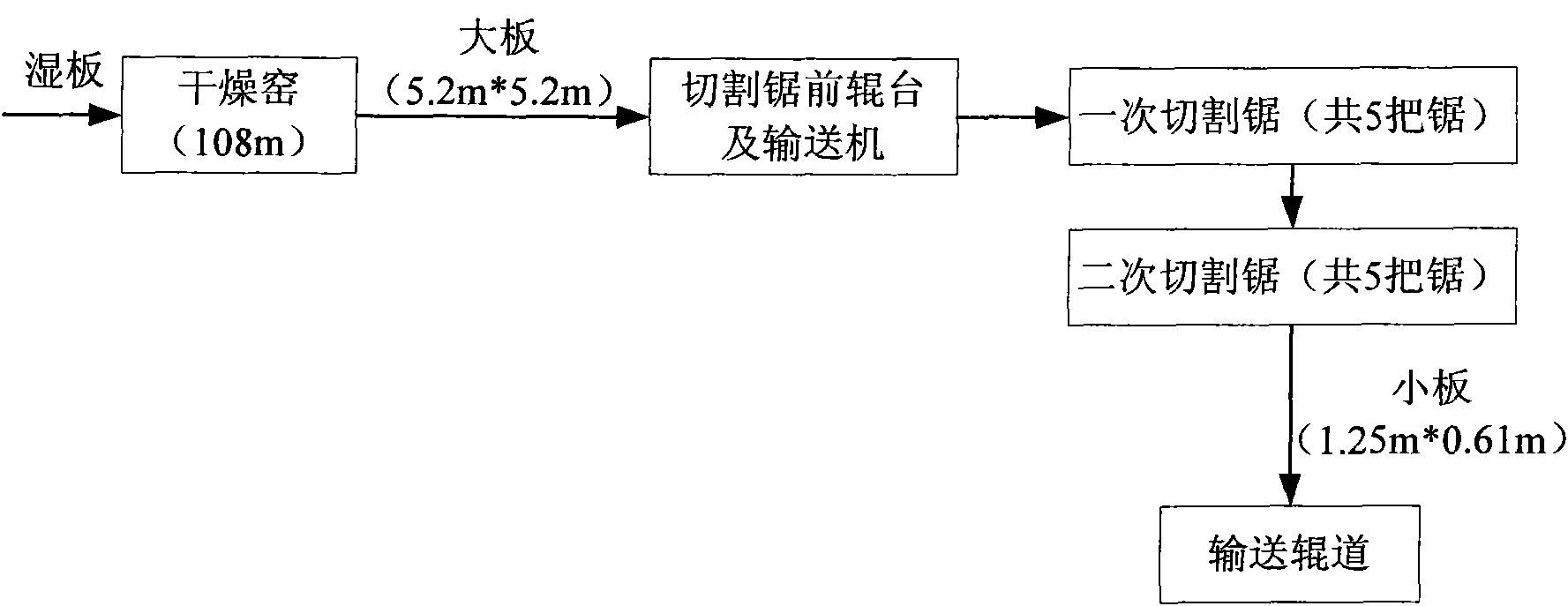

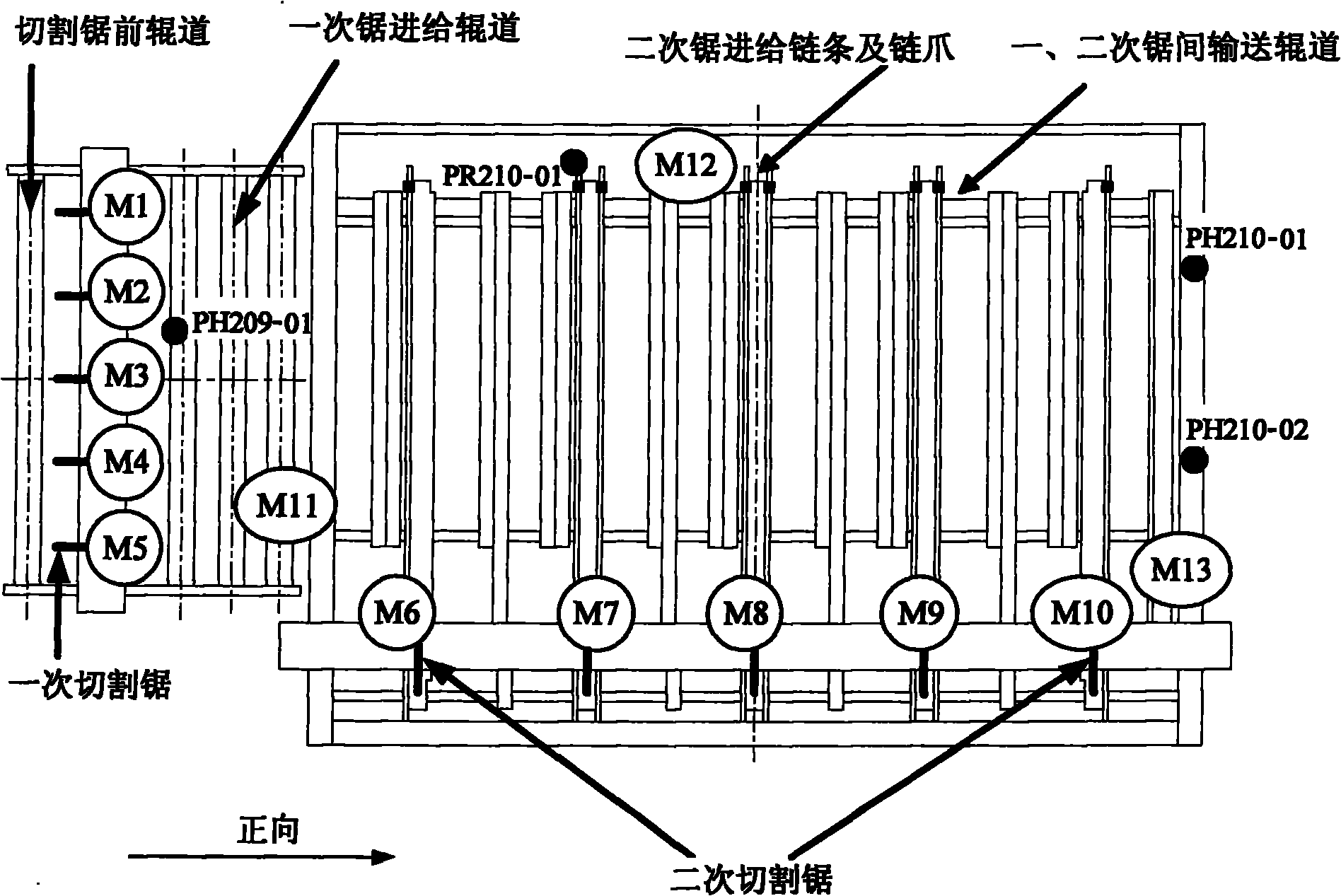

[0034] The present invention will be described in detail below with reference to the drawings and specific embodiments.

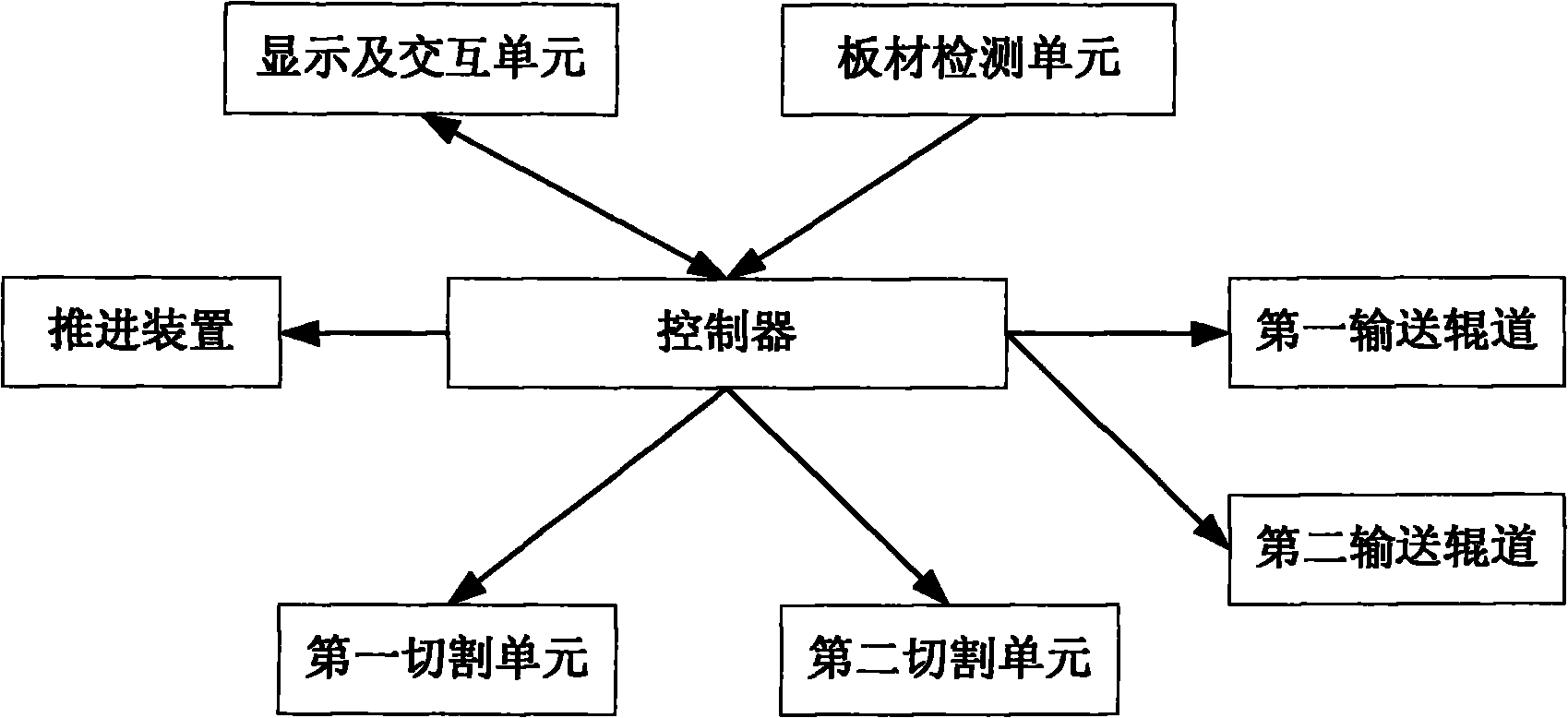

[0035] Such as figure 2 As shown, the control system includes a control unit, a first conveying roller table, a first cutting unit, a second conveying roller table, a second cutting unit, a sheet detection unit, and a propulsion device, among which:

[0036] The control unit is used to control the operation of the first conveying roller table, the first cutting unit, the second conveying roller table, and the second cutting unit. After receiving the signal sent by the sheet detection unit, it controls the operation of the propulsion device and controls the propulsion The device returns to the pre-set starting position;

[0037] The first conveying roller is used to convey uncut plates (original plates), and convey the cut plates to the second conveying roller;

[0038] The first cutting unit, which can be located above the first conveyor roller, is used to cut the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com