Ash poking hook for aluminium trichloride synthesizing sublimation pipe

A technology of anhydrous aluminum chloride and tube poking, applied in the direction of aluminum chloride, aluminum halide, etc., can solve problems such as damage to the inner wall of the sublimation tube, reduce the service life of the sublimation tube, etc., and achieve high-quality product rate, simple design, and practicability big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

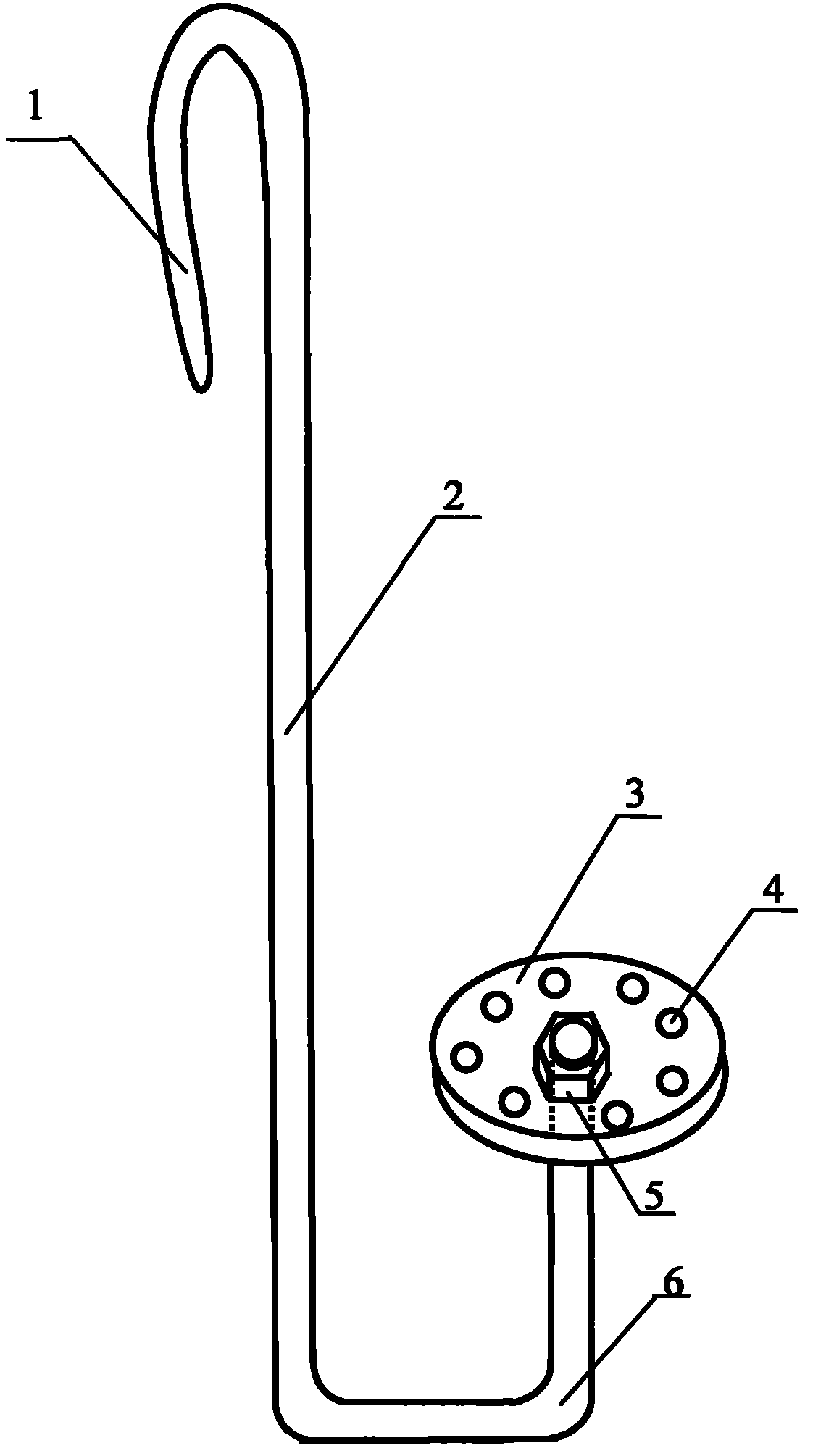

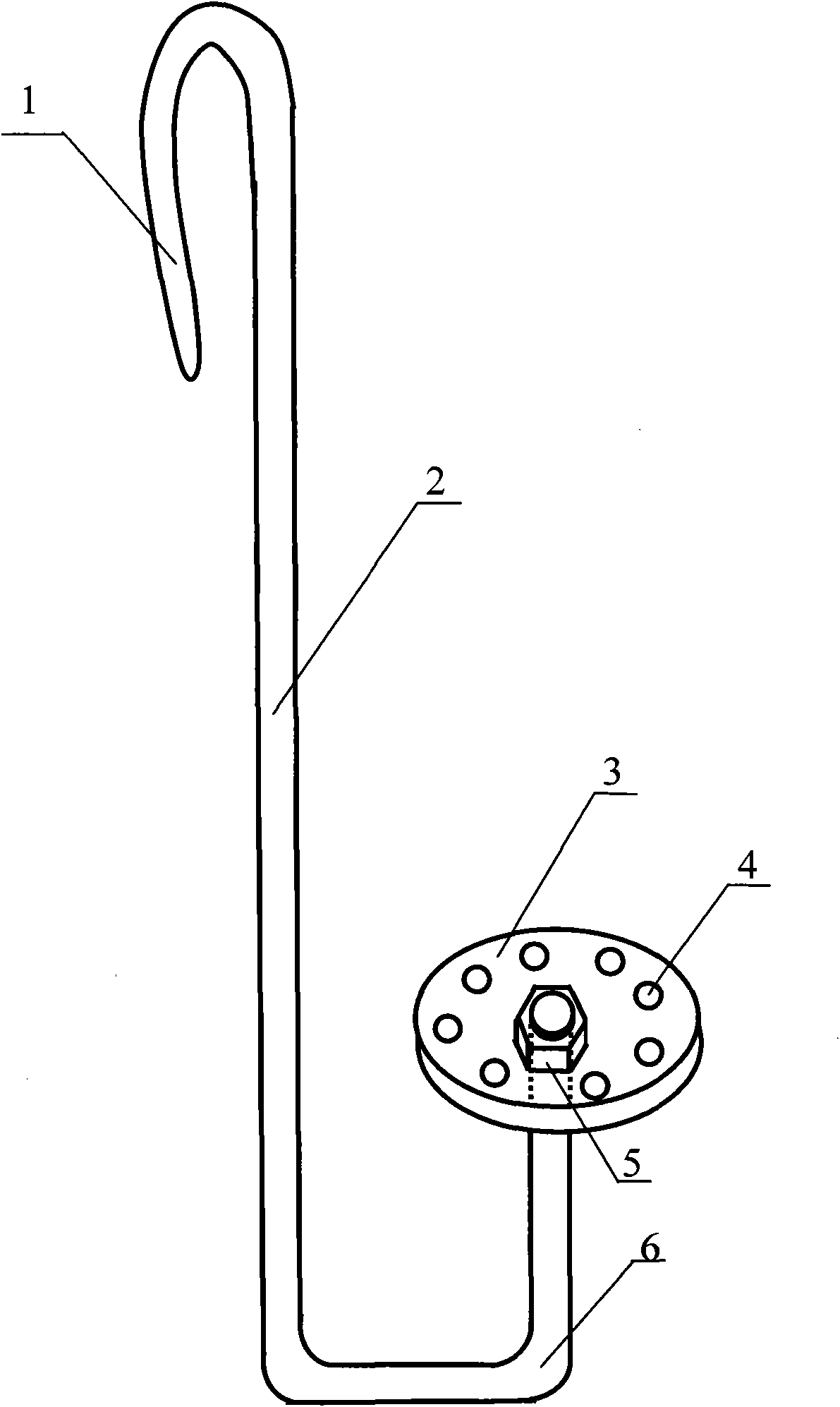

[0010] The present invention is made up of handle 1, long iron rod 2, ceramic circular plate 3, hole 4, nut 5, short iron rod 6, is characterized in that the vertical short iron rod 6 on the long iron rod 2 bottom horizontal bar of handle 1 is connected with Eight holes 4 have a ceramic disc 3 with a central round hole, the diameter of the ceramic disc 3 is 20 centimeters, the diameter of the hole 4 on the ceramic disc 3 is 1.5 cm, and the short iron rod 6 is inserted in the round hole at the center of the ceramic disc 3 The screw rod is fixed with a gasket and a nut 5. When in use, hold the handle 1 and enter the molten aluminum in the synthetic chlorination furnace vertically downwards, and put the ceramic disc 3 into the sublimation tube toward the lower mouth of the sublimation tube. , the handle 1 can be moved up and down, left and right, back and forth to scrape and poke the ash, so that the ash on the wall of the sublimation tube will fall into the molten aluminum and be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com