Weft density adjusting seat for weaving machine

A technology of adjusting seat and weft density, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of inaccurate installation accuracy, waste of materials, and inability to tightly mesh between gears, and achieve the effect of accurate and convenient installation.

Inactive Publication Date: 2010-08-25

WUHU KANGDAOER TEXTILE SCI

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The weft density adjustment seat used in the original loom is fixed on a steel plate, and then the steel plate is provided to install on the wall plate, which is a waste of material, and is not conducive to installation, and the installation accuracy is not accurate, so the gears cannot be tightly occluded. can't control effective mark-moving

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

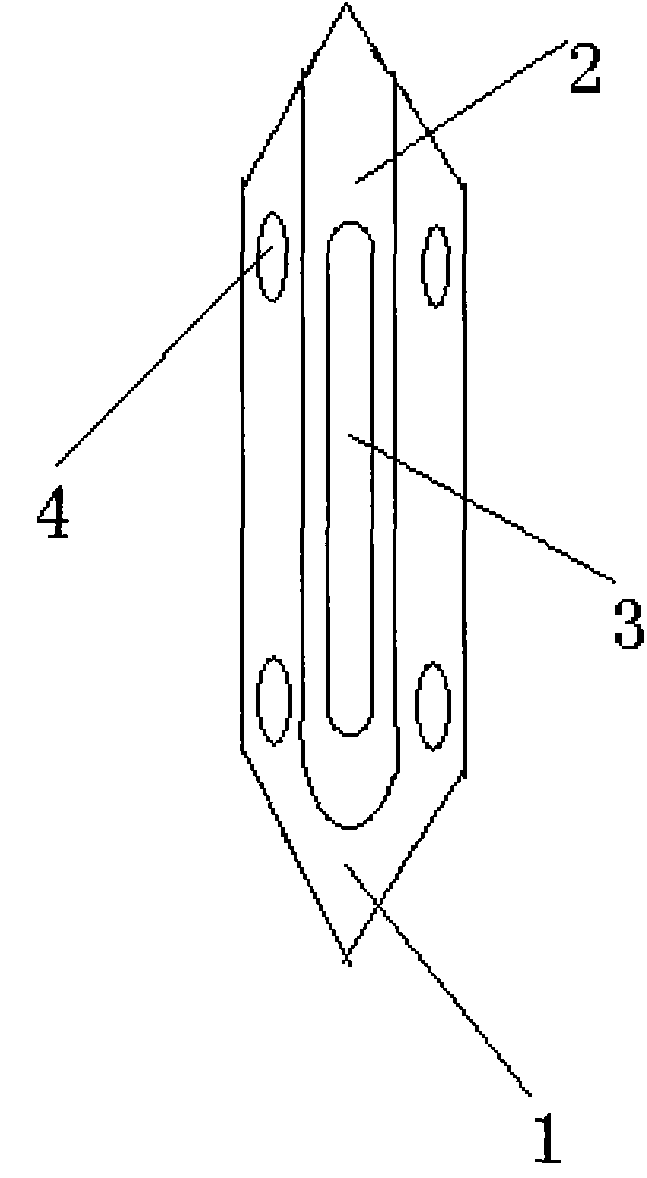

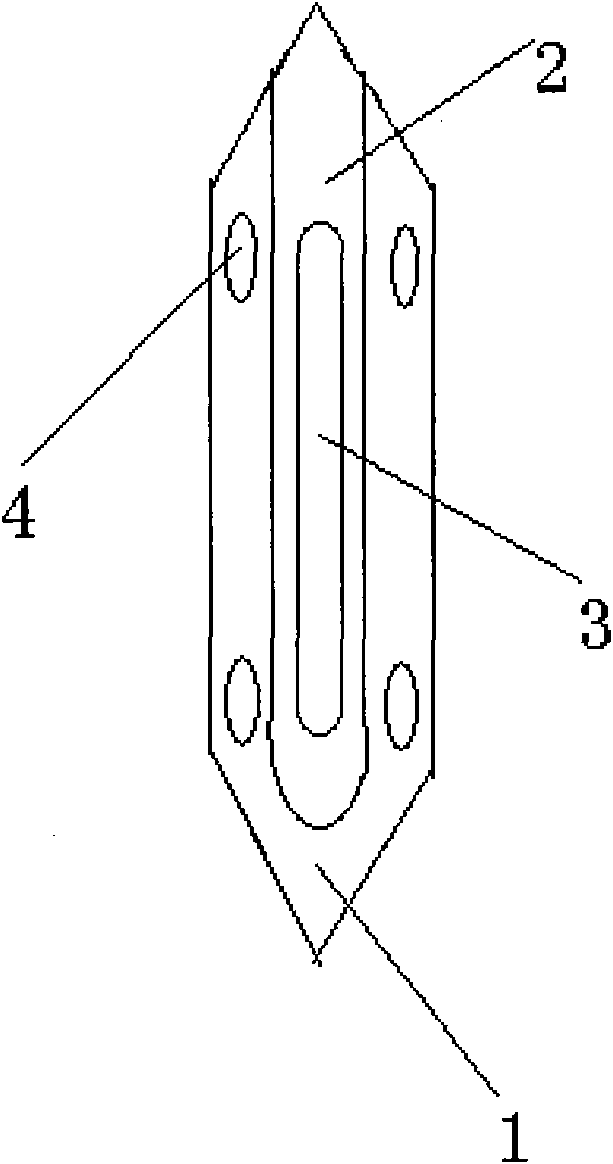

[0009] Referring to Fig. 1, a weft density adjusting seat of a loom comprises a shuttle-shaped seat 1, a bar-shaped groove 2 with one end closed and the other end open in the middle of the shuttle-shaped seat 1, a waist-shaped sinker 3 at the bottom of the bar-shaped groove 2, and a Bolt mounting holes 4 are installed on both sides of the shaped groove 2 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a weft density adjusting seat for a weaving machine. The weft density adjusting seat comprises a spindle-shaped seat, wherein the middle part of the spindle-shaped seat is provided with a strip-shaped groove of which one end is enclosed and the other end is open; the bottom of the strip-shaped groove is provided with a waist-shaped submerged groove; and the two sides of the strip-shaped groove are provided with bolt mounting holes. The weft density adjusting seat for the weaving machine has the advantages of accurate and convenient installation, simple and convenient replacement of a weft density gear, firm engagement of gears and effective control of misalignment.

Description

technical field [0001] The invention relates to textile looms, in particular to a loom weft density adjusting seat. Background technique [0002] The weft density adjustment seat used in the original loom is fixed on a steel plate, and then the steel plate is provided to install on the wall plate, which is a waste of material, and is not conducive to installation, and the installation accuracy is not accurate, so the gears cannot be tightly occluded. It is impossible to control the effective mark-moving. Contents of the invention [0003] The technical problem to be solved by the present invention is to provide a loom weft density adjustment seat, which is directly fixed and installed on the wallboard, and it is simple and convenient to replace the weft density gears, and the gears are meshed with each other tightly to effectively control the marking. [0004] In order to solve the problems of the technologies described above, the technical solution adopted in the present...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D03D49/00

Inventor 桑国海

Owner WUHU KANGDAOER TEXTILE SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com