Automatic yarn feeding device for full-automatic hank mercerizing machine

A mercerizing machine, fully automatic technology, used in yarn/thread/filament mercerization, textile processing machine accessories, textile material processing and other directions, can solve problems such as unfavorable workers' health, long machine standby time, and inconvenient labor protection. , to achieve the effect of realizing automatic operation, reducing standby time and easy speed regulation

Inactive Publication Date: 2010-08-25

SHANDONG TONGJI ELECTROMECHANICAL

View PDF5 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

On the skein mercerizing machine without an automatic yarn loading device, the operator needs to directly load and unload the mercerizing roller, which is labor-intensive, the machine has a long standby time, and the production efficiency is low; the operator works at a close distance and directly faces the alkaline mercerizing liquid, etc. Hazardous substances, poor working conditions, not conducive to the health of workers, and not convenient for labor protection

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

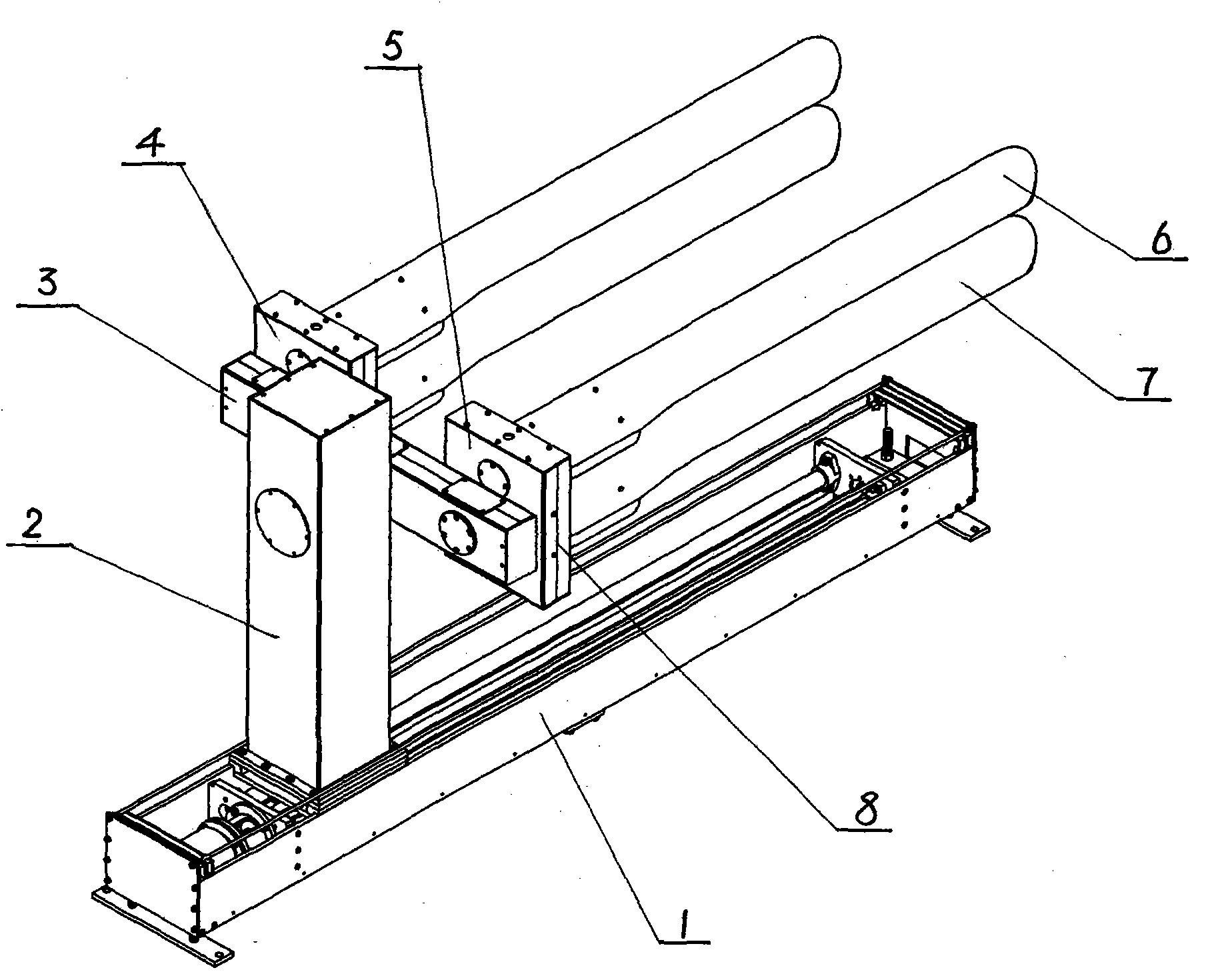

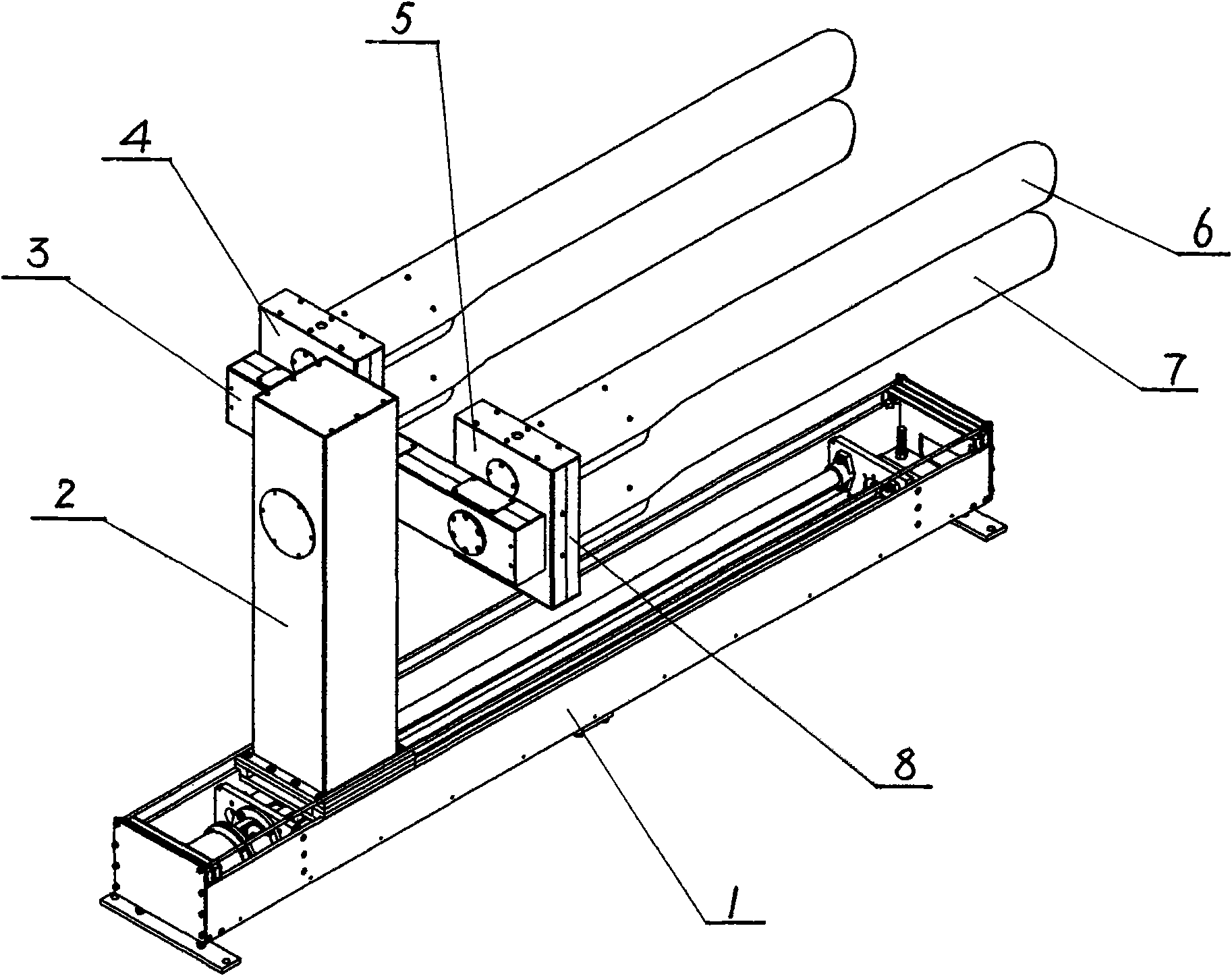

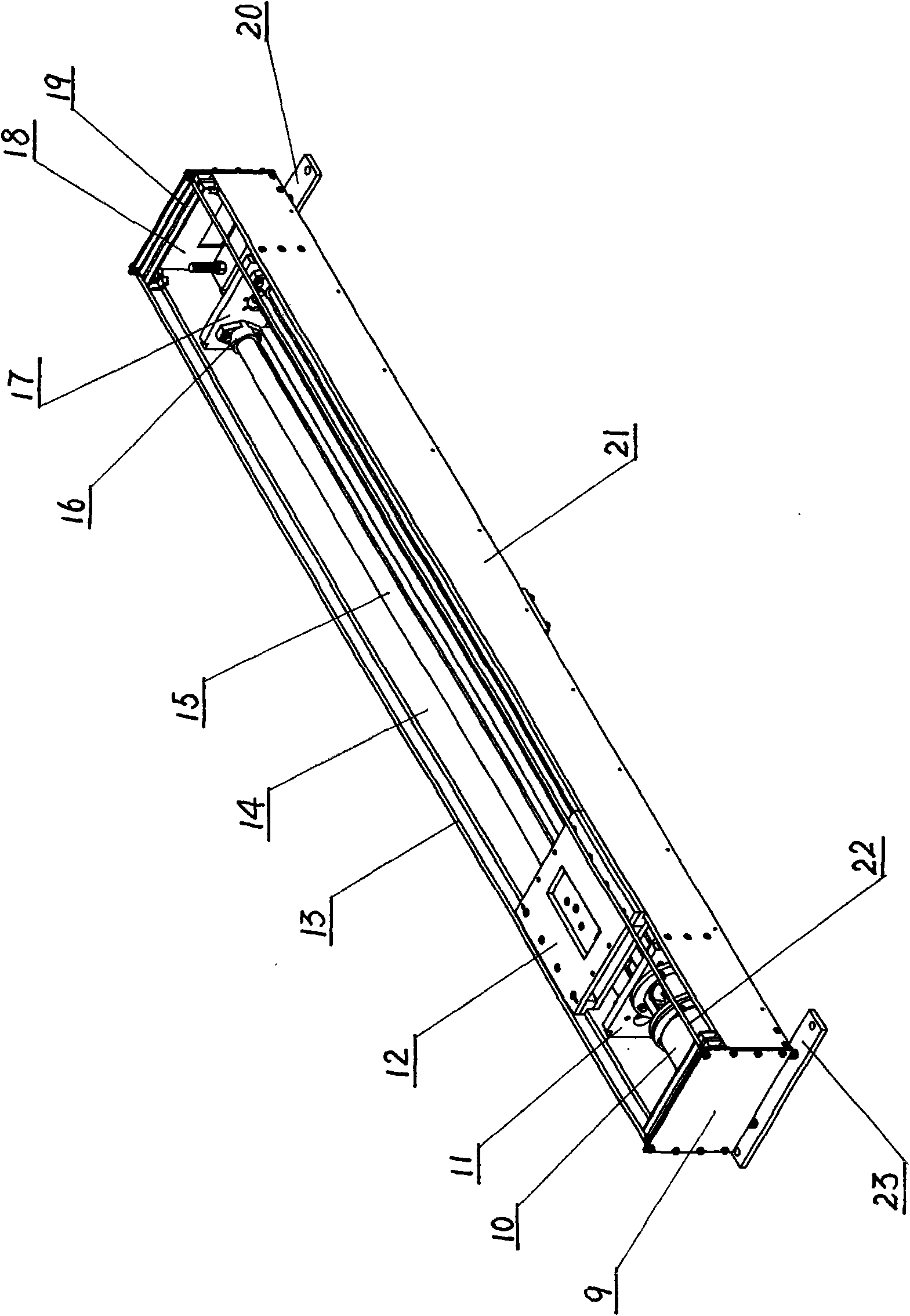

The invention discloses an automatic yarn feeding device for a full-automatic hank mercerizing machine, which improves the automation degree and production efficiency of the full-automatic hank mercerizing machine and improves the working conditions. The automatic yarn feeding device comprises a sliding table, an upright post, a swing arm and a yarn support tube bracket; a sliding table seat and a mechanism borne by the sliding table seat can enter or exit along the axis direction of a mercerizing roll to feed or discharge yarns for the mercerizing roll; the swing arm can rotate front and back 180 degrees on a horizontal plane to replace mercerized and non-mercerized yarns; and yarn bracket of the swing arm is provided with yarn support tubes, and the upper and lower opposite yarn support tubes form a group. During feeding yarns, the two yarn support tubes are inserted into the outer edge of the mercerizing roll in an opposite state and rotate 180 degrees in a reverse state, the unprocessed yarns fall on the mercerizing roll, and the yarn support tubes are retracted and separated from the mercerizing roll. During discharging the yarns, the two yarn support tubes are reversely inserted between the mercerizing rolls and rotate 180 degrees in an opposite state, the mercerized yarns fall on the yarn support tubes, and the yarn support tubes are retracted and separated from the mercerizing rolls.

Description

Automatic yarn loading device for fully automatic hank mercerizing machine technical field The invention belongs to the technical field of textile machinery equipment, and in particular relates to an automatic yarn feeding device used in conjunction with a fully automatic skein mercerizing machine. Background technique With the development of the textile industry and the improvement of consumers' requirements for the grade of textile products, domestic and foreign textile manufacturers have put forward higher and higher technical requirements for textile products. As the key process equipment for producing high-grade mercerized yarn, hank mercerizing machine has been adopted by more and more textile manufacturers. Fully automatic skein mercerizing machine has been produced and researched in China, such as the skein mercerizing machine produced by Shandong Kunyuan Textile Machinery Co., Ltd. and the fully automatic skein mercerizing machine produced by Wuxi Yangshi Xinghuo ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D06B23/00D06B23/04D06B7/06

Inventor 方中锋王炳伟盛凯朱峰宋秀丽

Owner SHANDONG TONGJI ELECTROMECHANICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com