Elemental chlorine free bleaching method for plant fiber stuff

A plant fiber and elemental chlorine technology, applied in pulp bleaching and other directions, to reduce environmental pollution, reduce pollution, and improve pulp strength

Active Publication Date: 2010-08-25

SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

View PDF3 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

CN1065578C only found the final bleaching section suitable for chemical wood pulp, and did not involve the bleaching of straw pulp

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

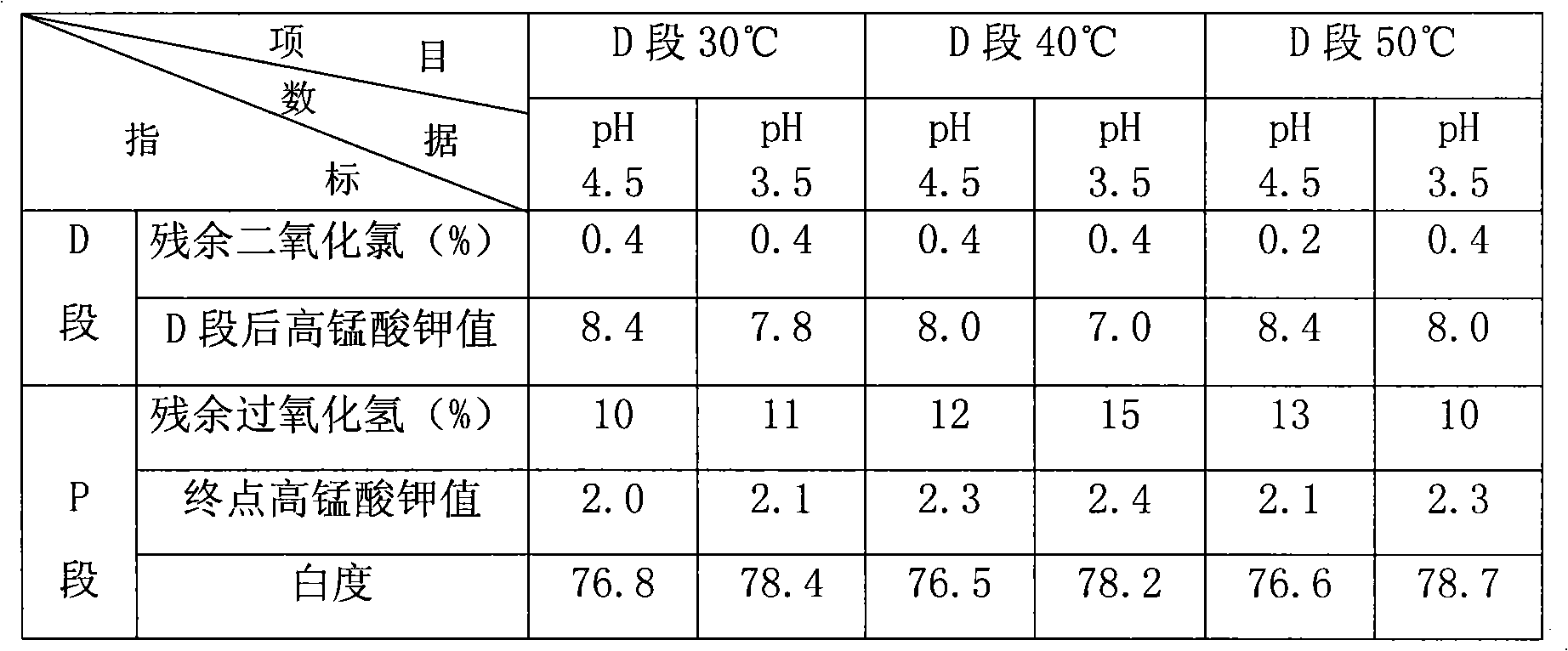

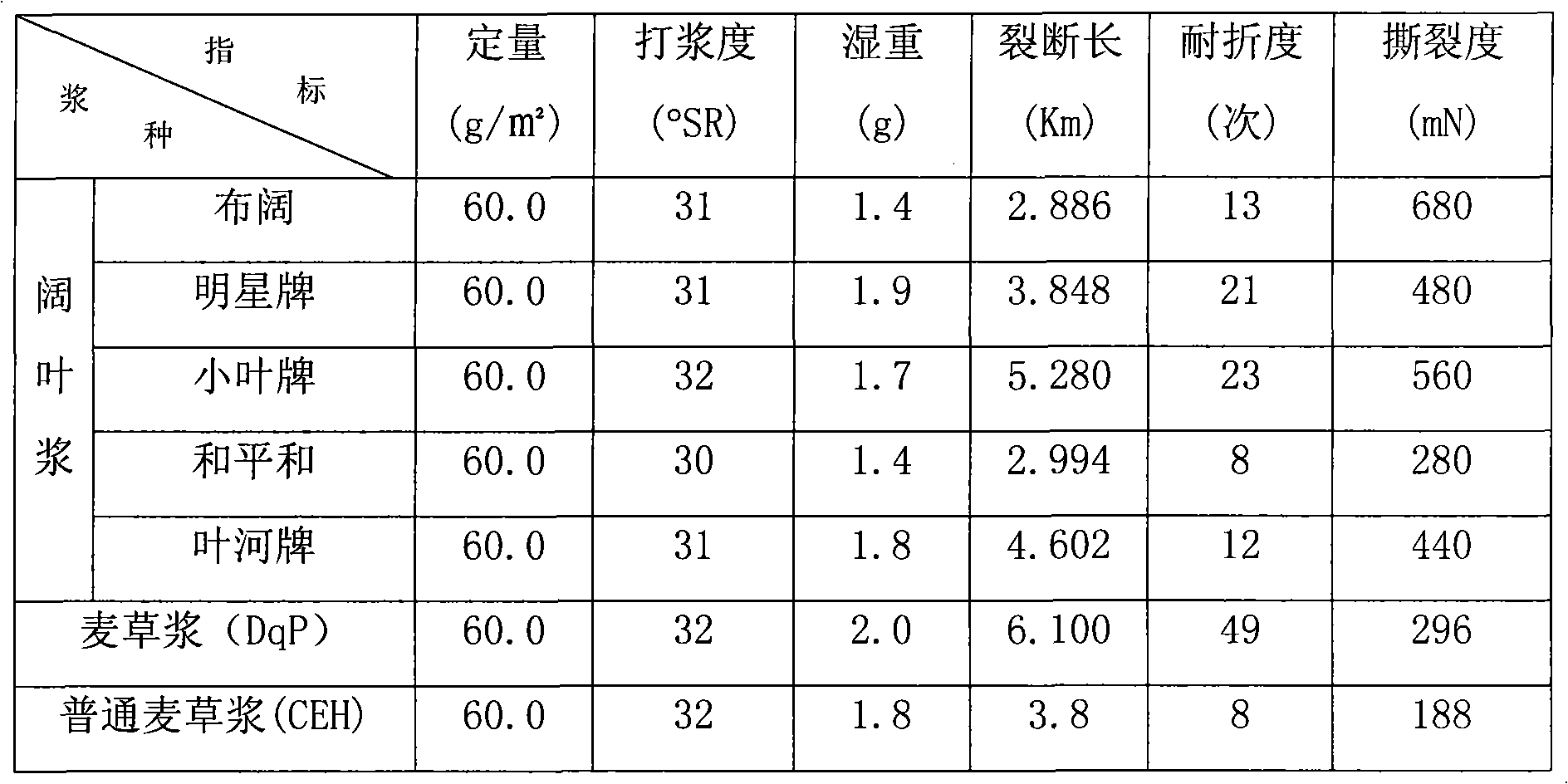

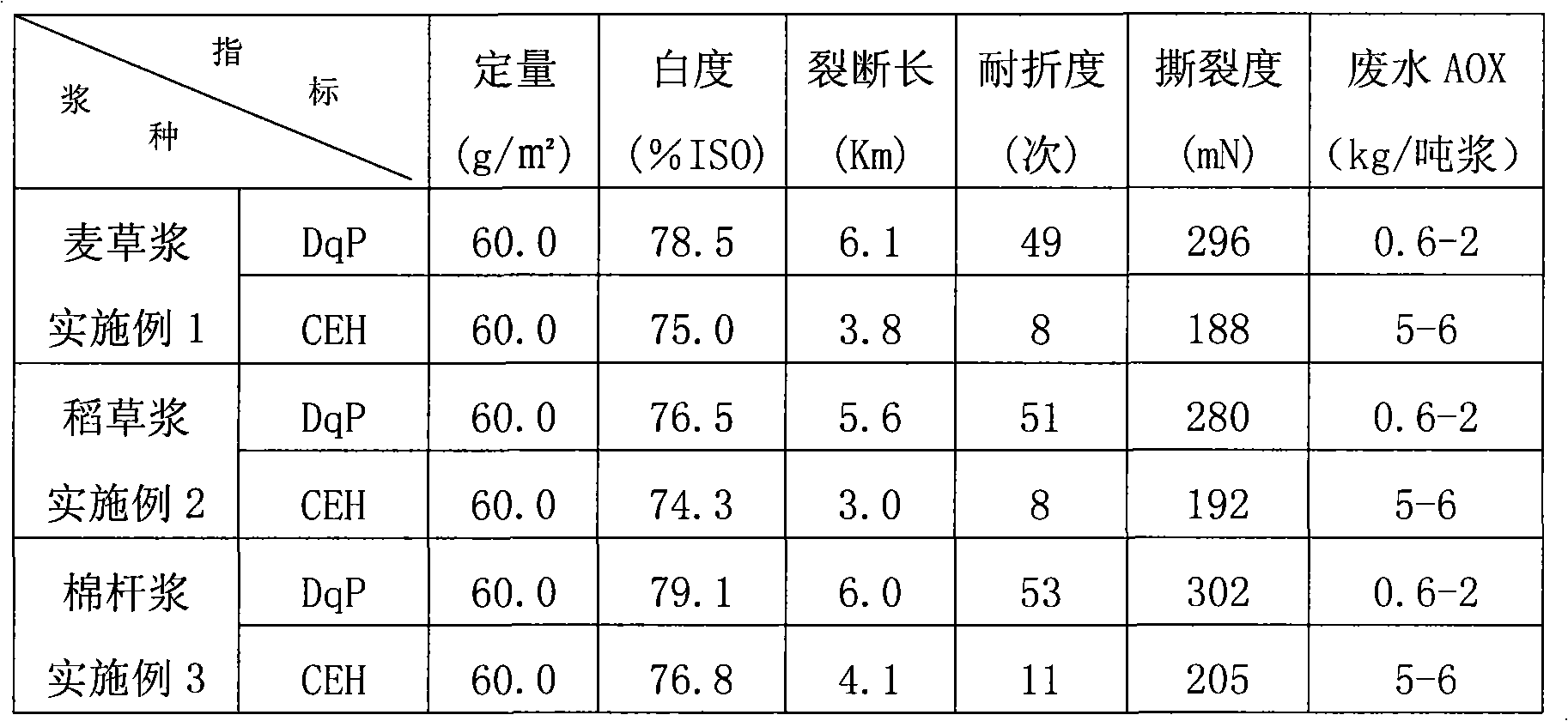

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to an elemental chlorine free bleaching method. In the method, dioxin and AOX are removed from the source by adopting D section bleaching and P section bleaching. The straw pulp is bleached by adopting the elemental chlorine free bleaching method, so that the problem that wastewater obtained by bleaching by the chlorine-containing bleaching method is most severely polluted is solved; and the bleaching process is simple and practicable. Each index of the bleached stuff can be compared with that of broadleaf wood pulp.

Description

technical field The invention relates to a method for bleaching pulp, in particular to a method for bleaching plant fiber pulp without elemental chlorine. Background technique The development of my country's pulp bleaching technology is slow, especially the straw pulp bleaching technology still uses chlorine and hypochlorite bleaching. It has been proved that this kind of bleaching wastewater contains a series of organic halides including dioxin and AOX, which will cause great harm to human health and the environment. The pollution caused by chlorine bleaching is quite serious, which is far from meeting the requirements Environmental Protection Requirements for Limiting the Discharge of Organic Halides in Bleaching Wastewater. At present, the use of chlorine bleaching methods has been expressly banned internationally. Therefore, it is imminent to find a chlorine-free bleaching method suitable for straw pulp as soon as possible. CN1940176A discloses a two-stage bleaching ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D21C9/10

Inventor 李洪法宋明信毕衍金赵淑晶阎俊钦金艳彬

Owner SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com