Connecting structure of resin composite material single-pipe tower

A technology of resin composite material and connecting structure, applied in towers, building types, buildings, etc., can solve problems such as insufficient firmness and bulky structure, and achieve the effects of convenient and simple installation, reduced production costs, and simple appearance

Active Publication Date: 2010-08-25

FUYANG WANXING TRAFFIC ENG

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The structure is bulky and the firmness is not enough

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

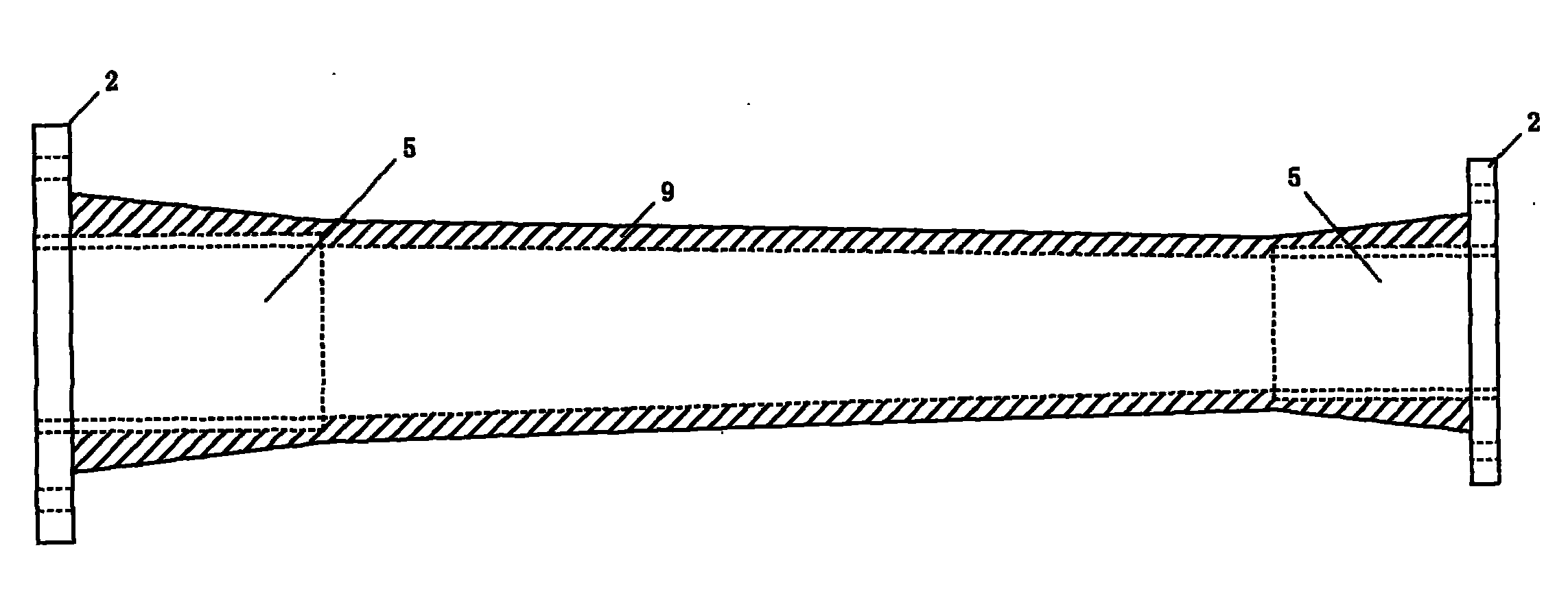

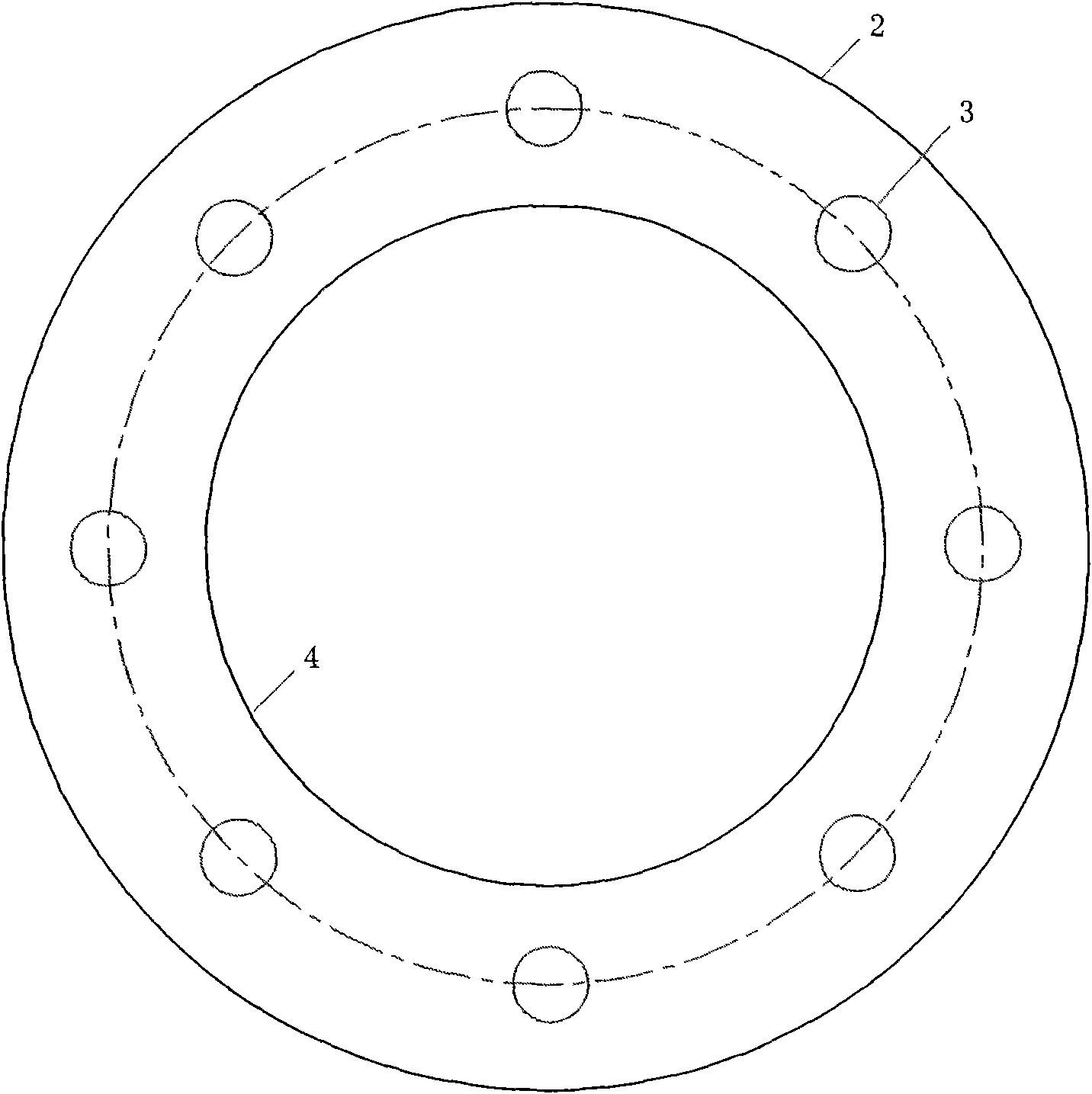

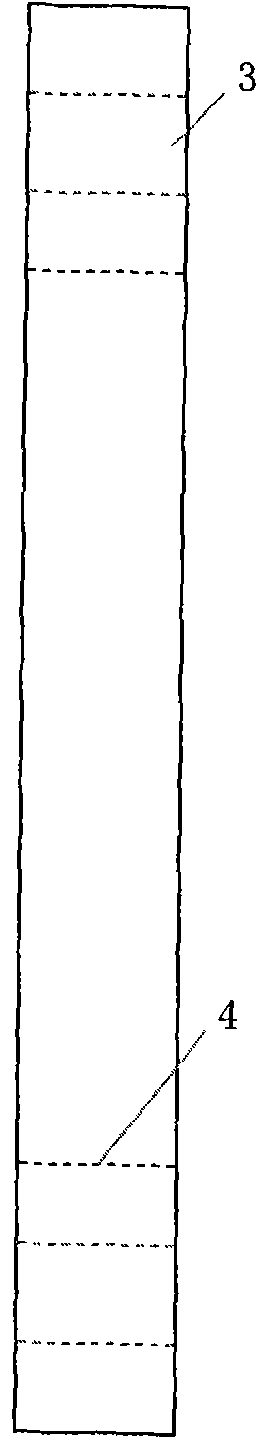

The invention discloses a connecting structure of a resin composite material single-pipe tower, which belongs to the technical field of pipe tower connecting pieces. The connecting structure comprises a tower body, a flange and a stay wire flange and has the main technical characteristics that: a lining pipe is arranged between the tower body and the flange; one end of the lining pipe is inlaid and welded with an inner ring of the flange or is nested and welded with an outer ring of the flange; and the tower body and the lining pipe are formed in a winding mode. The connecting structure makes the shape of a connecting steel pipe more compact and beautiful, and the processing and the mounting convenient and simple, and reduces the production cost. The connecting structure does not destroy the integrity and the aesthetic property of the tower body, and can determine the lining pipe with a corresponding length according to natural conditions such as the ground quality, the wind speed and the like of the place of the single-pipe tower, and design requirements so as to ensure that the connecting structure has enough wind resistance and twisting resistance.

Description

A resin composite single-pipe tower connection structure Technical field: The invention relates to a novel resin composite material single pipe tower connection technology, which belongs to the technical field of pipe tower connectors. Background technique: The existing single-pipe tower is generally connected from bottom to top by multi-section tower bodies, and the tower bodies of each section are connected by flanges and high-strength bolts. Cause structure bulky, firmness is not enough. Invention content: The invention proposes a resin composite single-pipe tower connection structure with lighter weight, novel concept, reasonable and simple structure, increased strength of the single-pipe tower, and suitable for connection between tower bodies such as resin composite single-pipe towers. The present invention is realized through the following technical solutions: a resin composite single-pipe tower connection structure, including a tower body, a flange, and a cable...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04H12/00

Inventor 赵欣荣

Owner FUYANG WANXING TRAFFIC ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com