Walking type horizontal directional drilling machine

A horizontal directional drilling rig and walking technology, which is applied in directional drilling and other directions, can solve the problems of prolonging the construction auxiliary operation time, poor adaptability of the construction site, and increasing the intensity of manual labor, etc., so as to shorten the construction auxiliary operation time and have strong adaptability , Convenient effect of transferring the construction site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

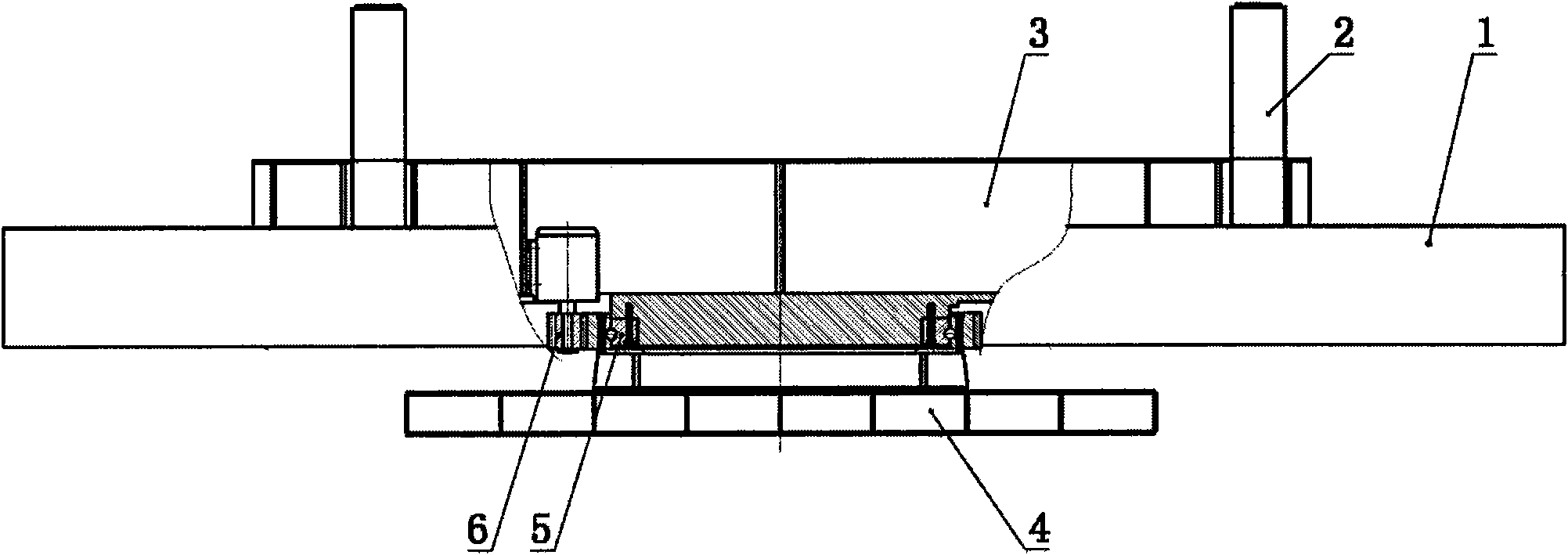

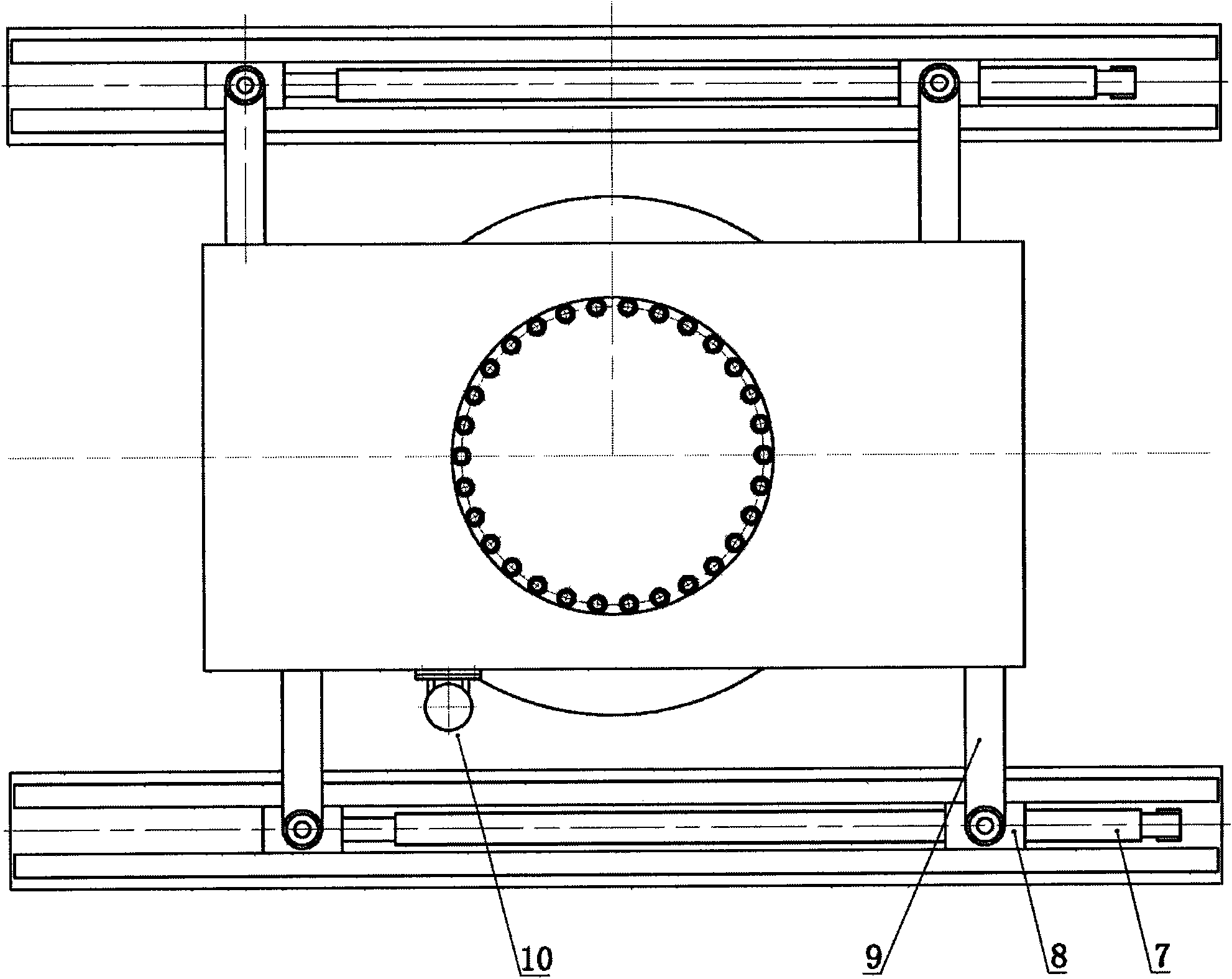

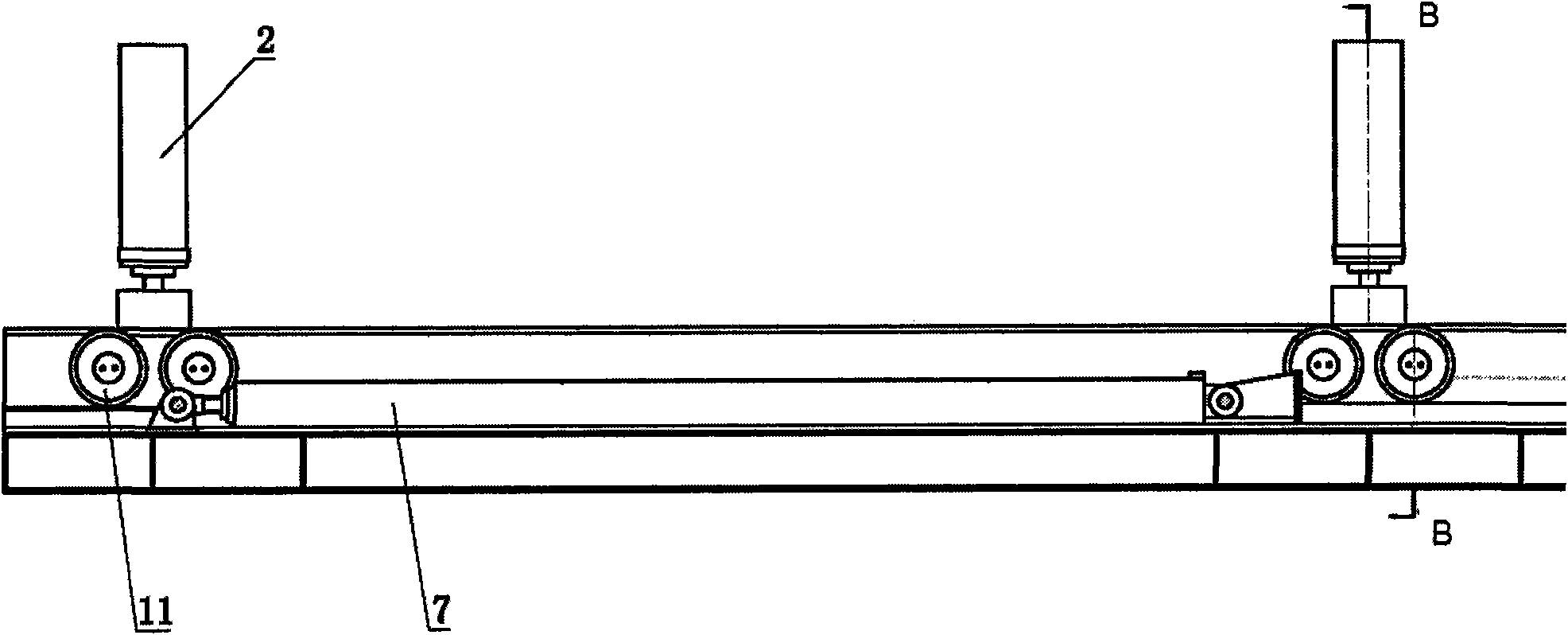

[0016] As shown in the figure, the walking mechanism of the horizontal directional drilling rig for non-excavation pipelaying includes large ship 1, outrigger cylinder 2, main body 3, slewing frame 4, slewing support 5, gear 6, large ship cylinder 7, trolley 8, Telescoping rod 9, motor 10, walking wheel 11.

[0017] Wherein the traveling mechanism of the large ship 1 is provided with a large ship oil cylinder 7 and a trolley 8, one end of the large ship oil cylinder 7 is fixed to the large ship 1 through a support, and the other end is fixed to a traveling trolley 8 through a support, and the traveling trolley 8 rolls on the guide rail of the large vessel. The expansion and contraction of the large ship oil cylinder 7 can make the main body 3 move along the direction of the guide rail, thereby driving the horizontal drilling machine to move back and forth along the direction of the guide rail of the large ship.

[0018] Wherein the outrigger oil cylinder 2 connects the dolly 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com