Construction method for loop type hypobaric holes of railway tunnel

A tunnel and loop technology, applied in the field of construction of high-speed railway tunnel entrances, can solve problems such as limited use, longer distance and time for trains to pass through tunnels, and reduced ride comfort, so as to reduce pressure peaks and pressure gradients, and reduce air pressure. Dynamic effect, effect of increasing ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

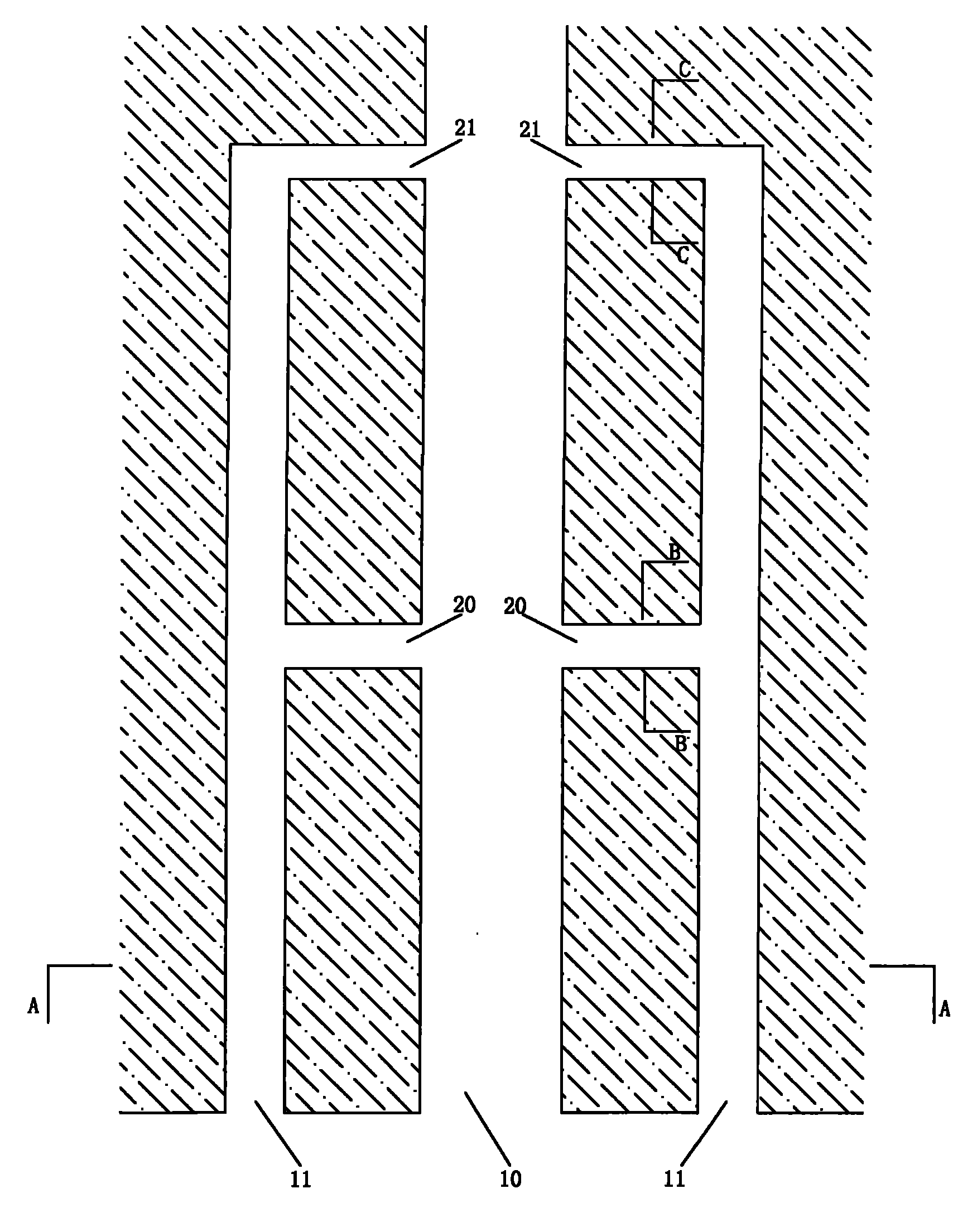

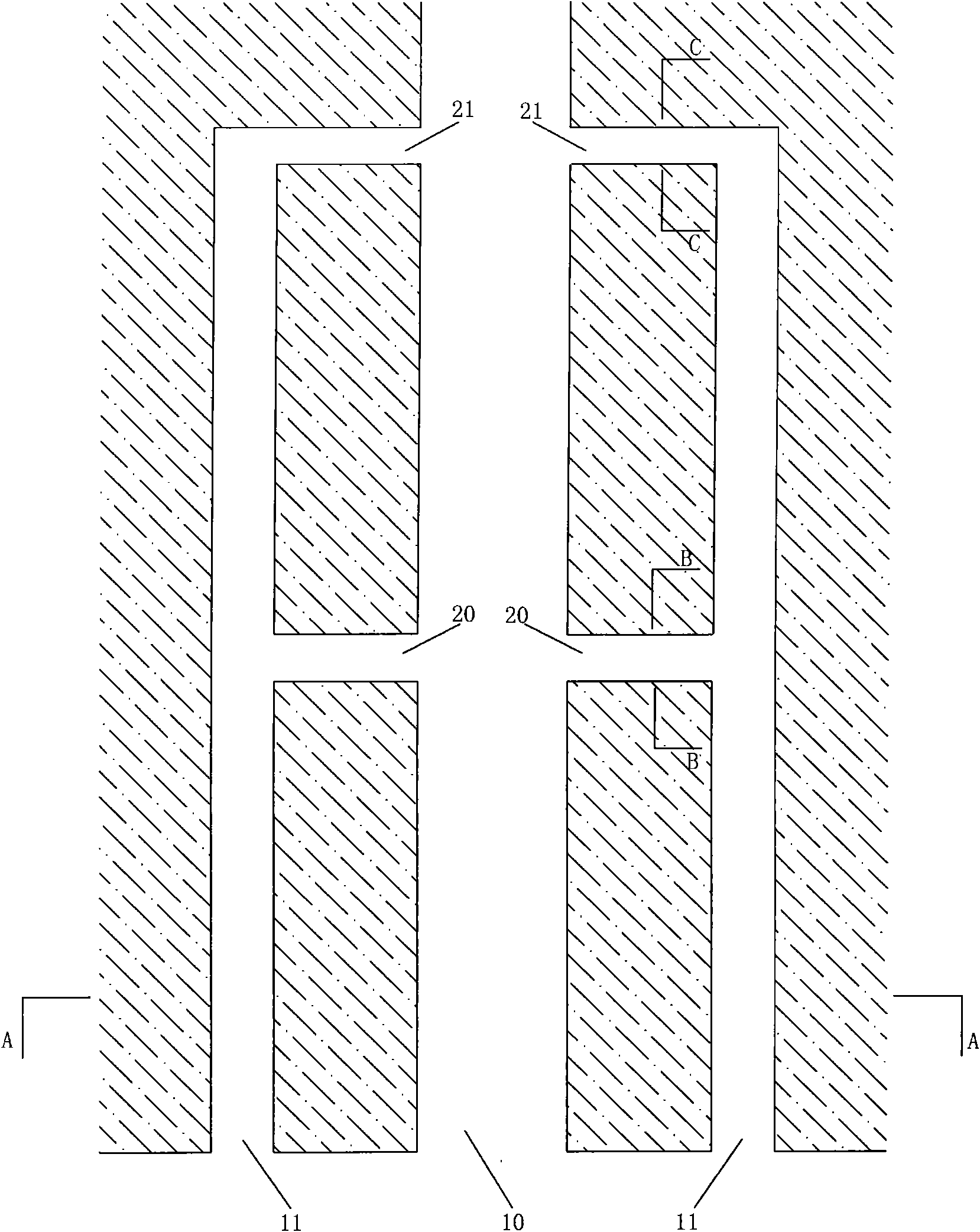

[0019] Fig. 1-4 shows, and a kind of embodiment of the present invention is, a kind of construction method of railway tunnel circuit type decompression hole, and its way is:

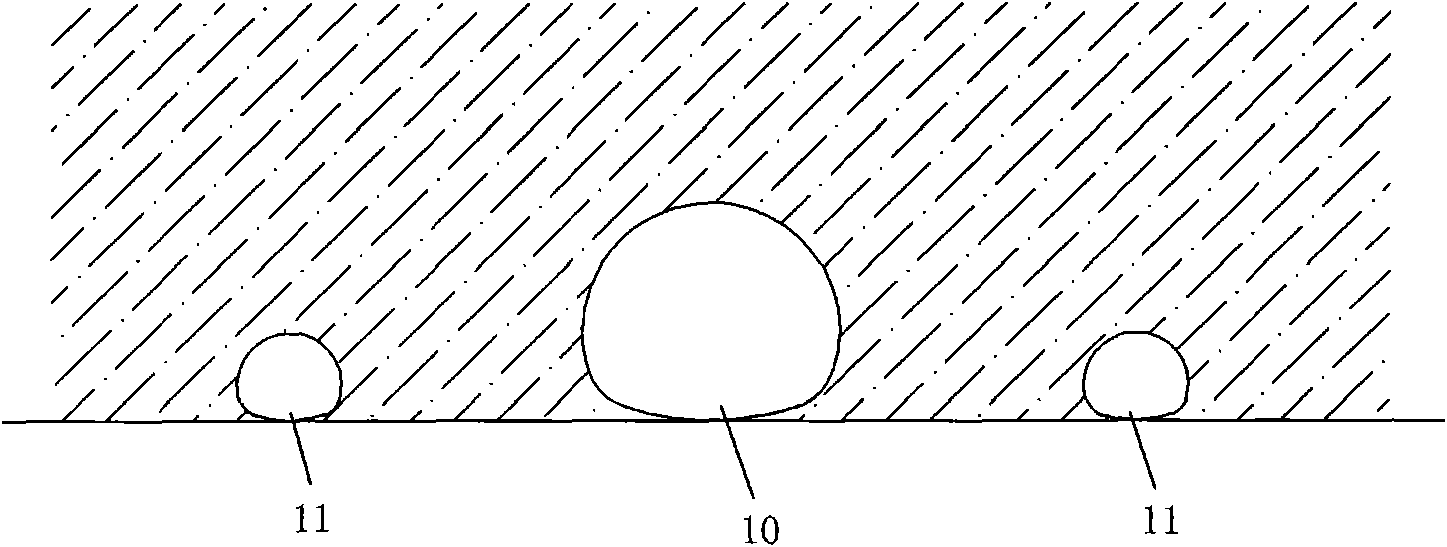

[0020] A. Build a side guide tunnel 11 parallel to the tunnel and having a length of 3.5-4.5 times the hydraulic diameter of the tunnel on both sides of the tunnel 10. The lateral distance between the side guide tunnel and the tunnel is 0.8-1.3 times the hydraulic diameter of the tunnel. The sectional area is 20%-30% of the tunnel sectional area;

[0021] B. Build two first and second cross passages 20, 21 between the guide tunnels on both sides and connect the side guide tunnels and tunnels. The first cross passage 20 is built at 1.5-2 times the tunnel hydraulic diameter from the tunnel entrance. , the sectional area is 10%-15% of the sectional area of the tunnel; the second transverse channel 21 is connected with the inner end of the side guide tunnel, and the sectional area is 5%-10% of the sectiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com