A crankcase structure of internal-combustion engine

A technology for crankcases and internal combustion engines, which is applied to the cooling of engines, mechanical equipment, and engine components. It can solve problems such as increased wall thickness and increased weight of internal combustion engines, and achieve the effects of preventing expansion or contraction deformation and suppressing weight increases.

Inactive Publication Date: 2010-08-25

HONDA MOTOR CO LTD

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to ensure the rigidity and strength required for mounting and supporting the radiator at the opening end of the large opening of the cylindrical peripheral wall, the thickness of the cylindrical peripheral wall is increased to cope with the increase in the weight of the internal combustion engine.

In addition, when the internal combustion engine is supported on the vehicle frame via the engine hanger protruding from the crankcase, since it is necessary to ensure the strength of the root of the engine hanger where the force of the cylindrical peripheral wall of the crankcase is concentrated, the wall thickness of this part is increased. leading to a further increase in the weight of the internal combustion engine

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

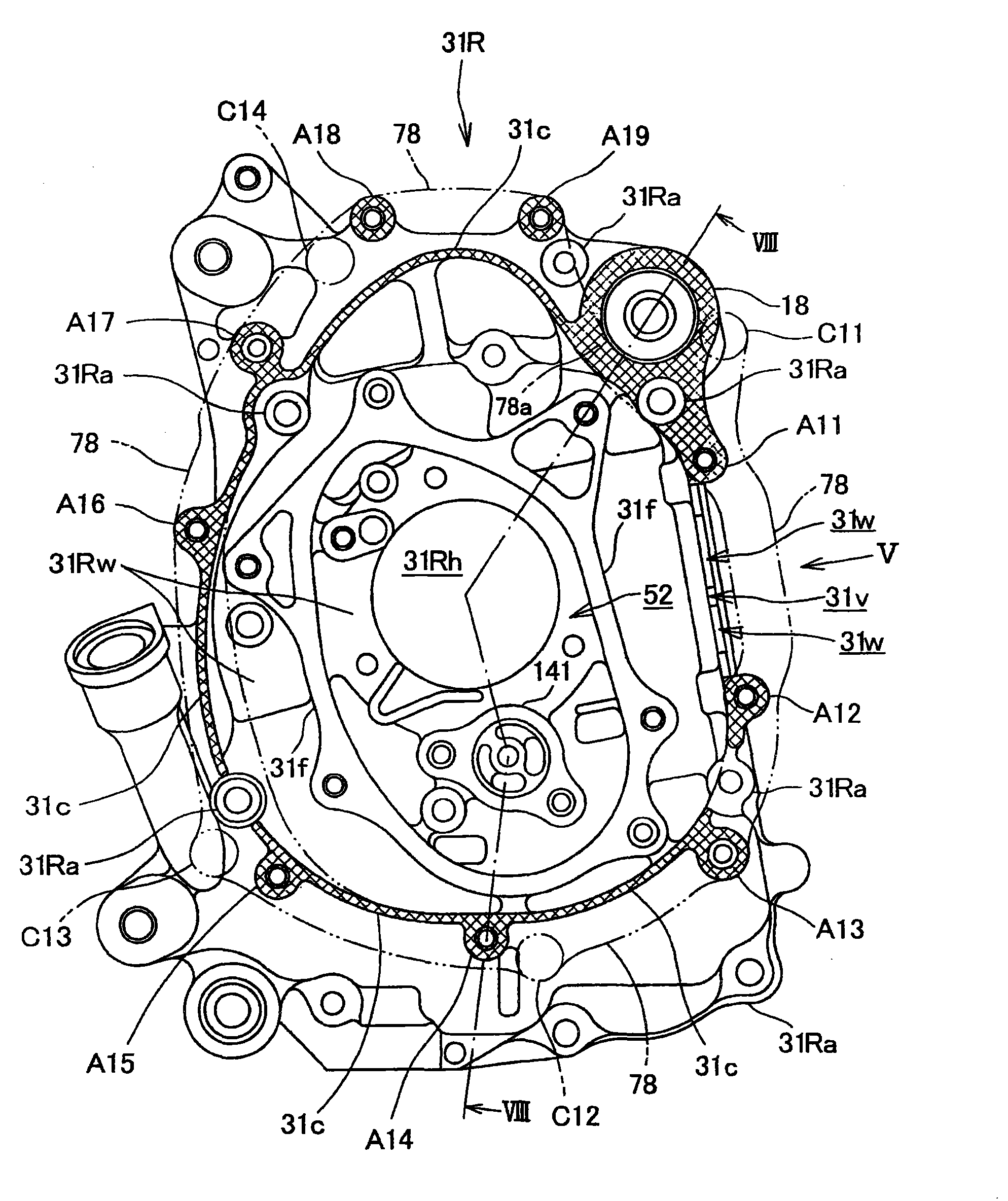

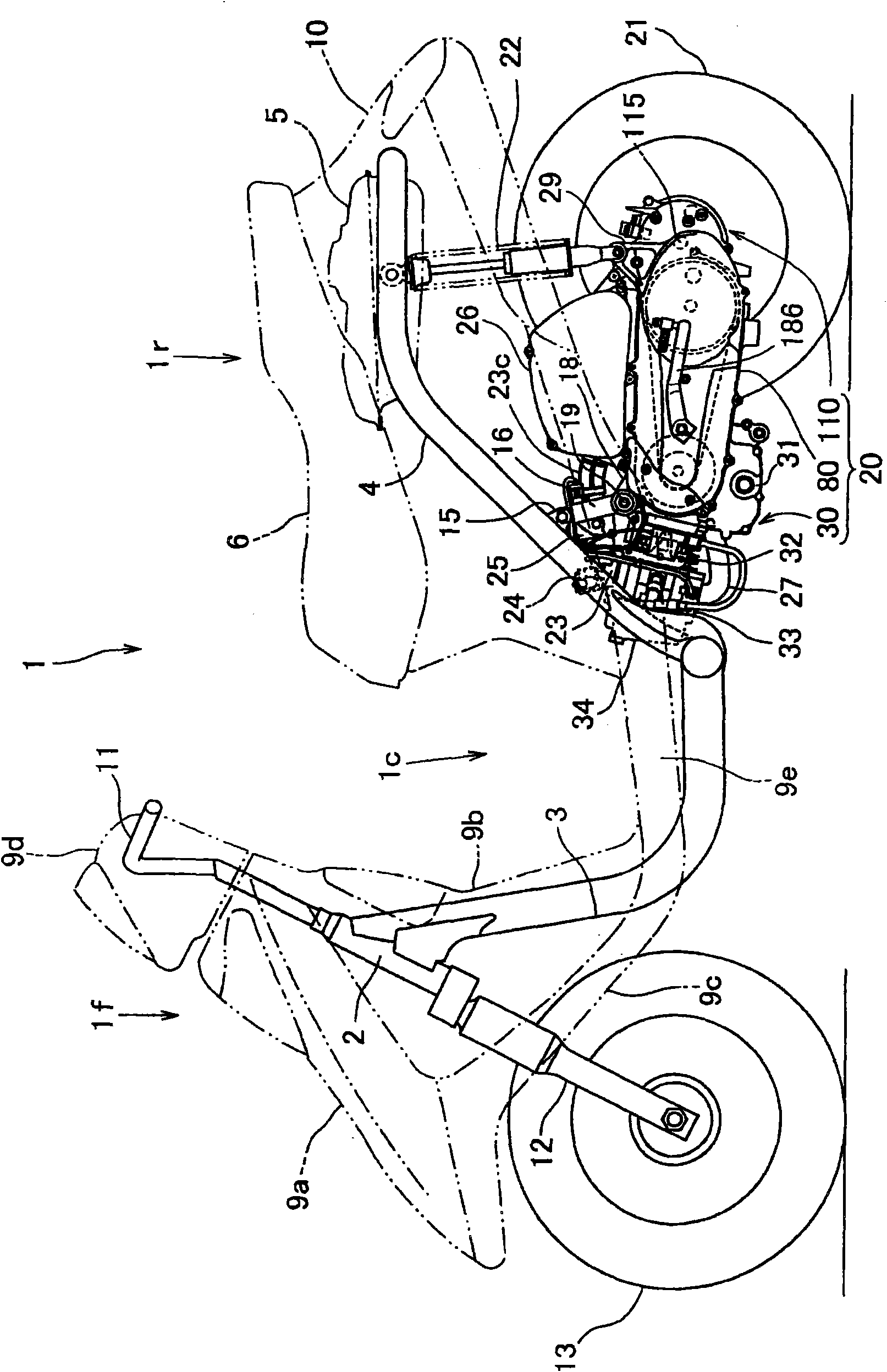

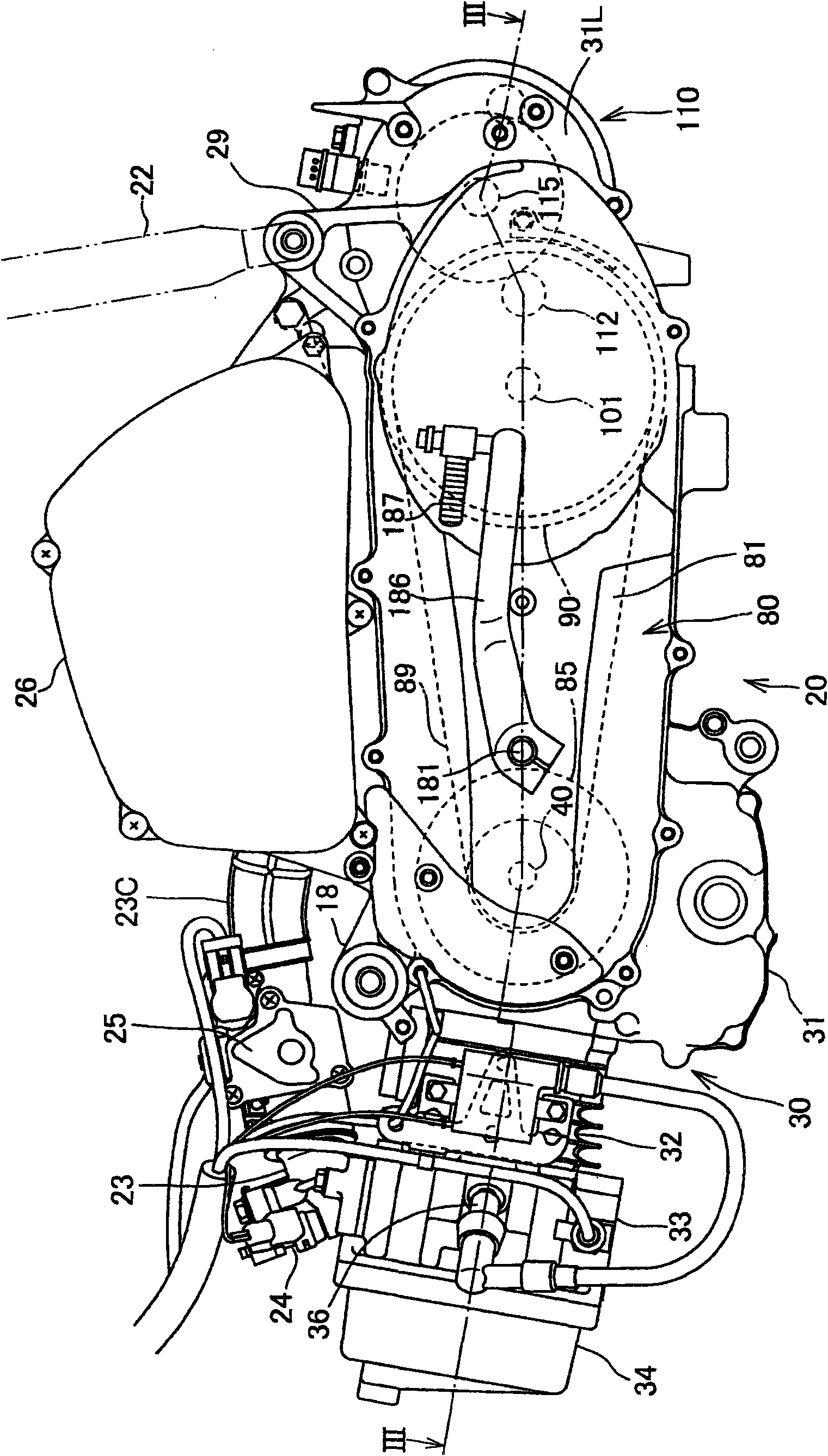

This invention provides a crankcase structure of internal-combustion engine which can limit the thickness of the tubular walls of the crankcase and restrain the increase of the weight, ensure the needed rigidity and intensity at the same time. In crankcase structure of said internal-combustion engine, side walls (31Rw)of crankcase extends outside of the crankshaft to form tubular walls(31c), a case cover(77) covers the opening of the tubular walls(31c). Said crankcase structure of internal-combustion engine is supported by connecting the engine hanger(18) formed in the tubular walls(31c)with the frame, where the annular case strengthen part(78) that forms a annular shape along the opening end of the tubular walls(31c)and has thickness in radial direction is fixed on the opening end of the tubular walls(31c)by means of overlapping local part of the engine hanger(18).

Description

Crankcase structure of internal combustion engine technical field The invention relates to a crankcase structure of an internal combustion engine. Background technique Various examples have been proposed for the crankcase structure of an internal combustion engine. For example, a crankcase in which a crankshaft of an internal combustion engine is pivotally supported by a side wall has a cylindrical peripheral wall extending outward in the direction of the crankshaft from the side wall in such a manner as to surround an AC generator or the like. The AC generator is provided on a crankshaft protruding outward from a side wall (for example, refer to Patent Document 1). Patent Document 1: (Japanese) Unexamined Patent Publication No. 2005-233012 In this patent document 1, the AC generator is surrounded by a cylindrical peripheral wall extending from the side wall of the crankcase, and a radiator is mounted and supported on the opening end of the large opening. outside. In...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F02F7/00F01P3/04

CPCF21V11/08F21V19/0035F21V23/003F21W2121/00F21Y2105/18F21Y2115/10Y10S362/80

Inventor 堀井宣孝土屋粒二相原顺二佐藤和夫

Owner HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com