Plastic part surface treatment agent for injection molding surface defect repair and preparation method thereof

A surface treatment agent and defect repair technology, applied in coatings and other directions, can solve the problems of low comprehensive environmental protection performance, affect the appearance of plastic parts, increase the wall thickness of plastic parts, etc., to improve the uniformity of dissolution, excellent repair ability, and reduce time. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

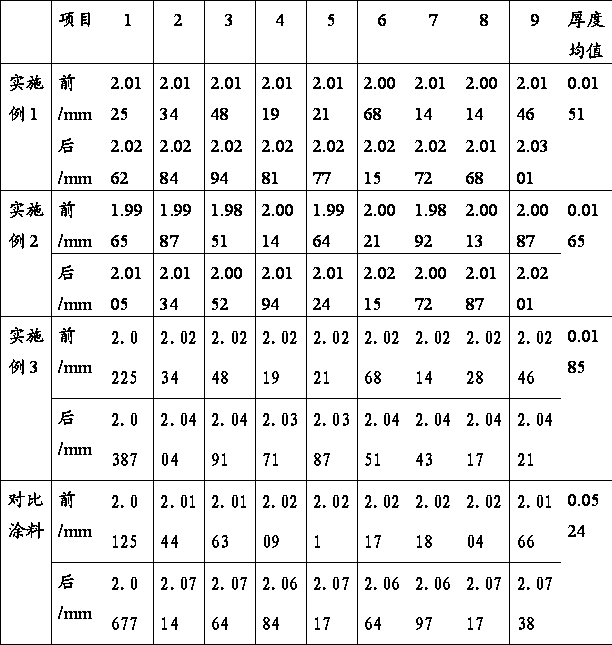

Examples

Embodiment 1

[0029] A plastic part surface treatment agent for repairing surface defects of injection molding, the invention provides a plastic part surface treatment agent for repairing surface defects of injection molding, comprising: cyclohexanone, ethylene glycol ethyl ether acetate, diacetone alcohol, dichloropropane , ethanol, ratio by weight is as follows:

[0030] Cyclohexanone 25wt%

[0031] Ethylene glycol ether acetate 25wt%

[0032] Diacetone Alcohol 20wt%

[0033] Dichloropropane 25wt%

[0034] Ethanol 5-wt%

[0035] The preparation method is as follows:

[0036] 1) Premix 25wt% cyclohexanone, 5wt% ethanol, and 20wt% diacetone alcohol;

[0037] 2) Then stir with a paint disperser;

[0038] 3) Add 25wt% ethylene glycol ether acetate and 25wt% dichloropropane;

[0039] 4) Disperse for 15 minutes at a speed of 800r / min;

[0040] 5) Conduct viscosity detection of the above mixture and observe the surface of the spray plate;

[0041] 6) After passing the above tests, use a...

Embodiment 2

[0043] A plastic part surface treatment agent for repairing surface defects of injection molding, the invention provides a plastic part surface treatment agent for repairing surface defects of injection molding, comprising: phenylcyclohexanone, ethylene glycol ethyl ether acetate, diacetone alcohol, 1 , 2-dichloropropane, ethanol, by weight ratio as follows:

[0044] Phenylcyclohexanone 35wt%

[0045] Ethylene glycol ether acetate 15wt%

[0046] Diacetone Alcohol 15wt%

[0047] 1,2-Dichloropropane 20wt%

[0048] Ethanol 15wt%

[0049] The preparation method is as follows:

[0050] 1) Premix 35wt% cyclohexanone, 15wt% ethanol, and 15wt% diacetone alcohol;

[0051] 2) Then stir with a paint disperser;

[0052] 3) Add 15wt% ethylene glycol ether acetate and 20wt% dichloropropane;

[0053] 4) Disperse at a speed of 500r / min for 20min;

[0054] 5) Conduct viscosity detection of the above mixture and observe the surface of the spray plate;

[0055] 6) After passing the abov...

Embodiment 3

[0057] A plastic part surface treatment agent for repairing surface defects of injection molding, the invention provides a plastic part surface treatment agent for repairing surface defects of injection molding, comprising: cyclohexanone, ethylene glycol ethyl ether acetate, diacetone alcohol, dichloropropane , ethanol, ratio by weight is as follows:

[0058] Cyclohexanone 30wt%

[0059] Ethylene glycol ether acetate 20wt%

[0060] Diacetone Alcohol 20wt%

[0061] Dichloropropane 20wt%

[0062] Ethanol 10wt%

[0063] The preparation method is as follows:

[0064] 1) Premix 30wt% cyclohexanone, 10wt% ethanol, and 20wt% diacetone alcohol;

[0065] 2) Then stir with a paint disperser;

[0066] 3) Add 20wt% ethylene glycol ether acetate and 20wt% dichloropropane;

[0067] 4) Disperse at a speed of 600r / min for 18 minutes;

[0068] 5) Conduct viscosity detection of the above mixture and observe the surface of the spray board;

[0069] 6) After passing the above tests, use a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com