A crankcase structure of internal-combustion engine

A technology for crankcases and internal combustion engines, applied to the cooling of engines, mechanical equipment, engine components, etc., which can solve problems such as thickening and increasing the weight of internal combustion engines, and achieve the effect of preventing expansion or contraction deformation and suppressing weight increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

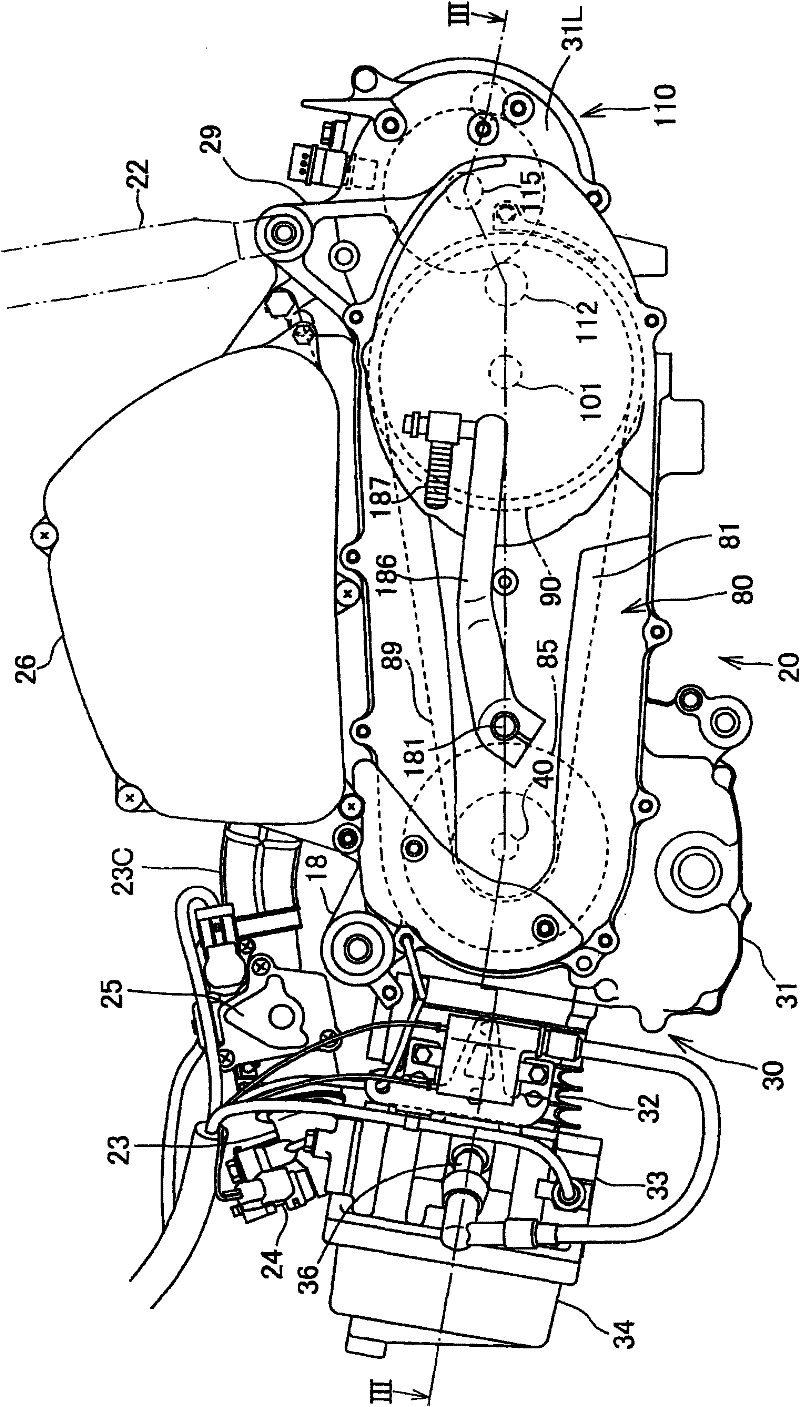

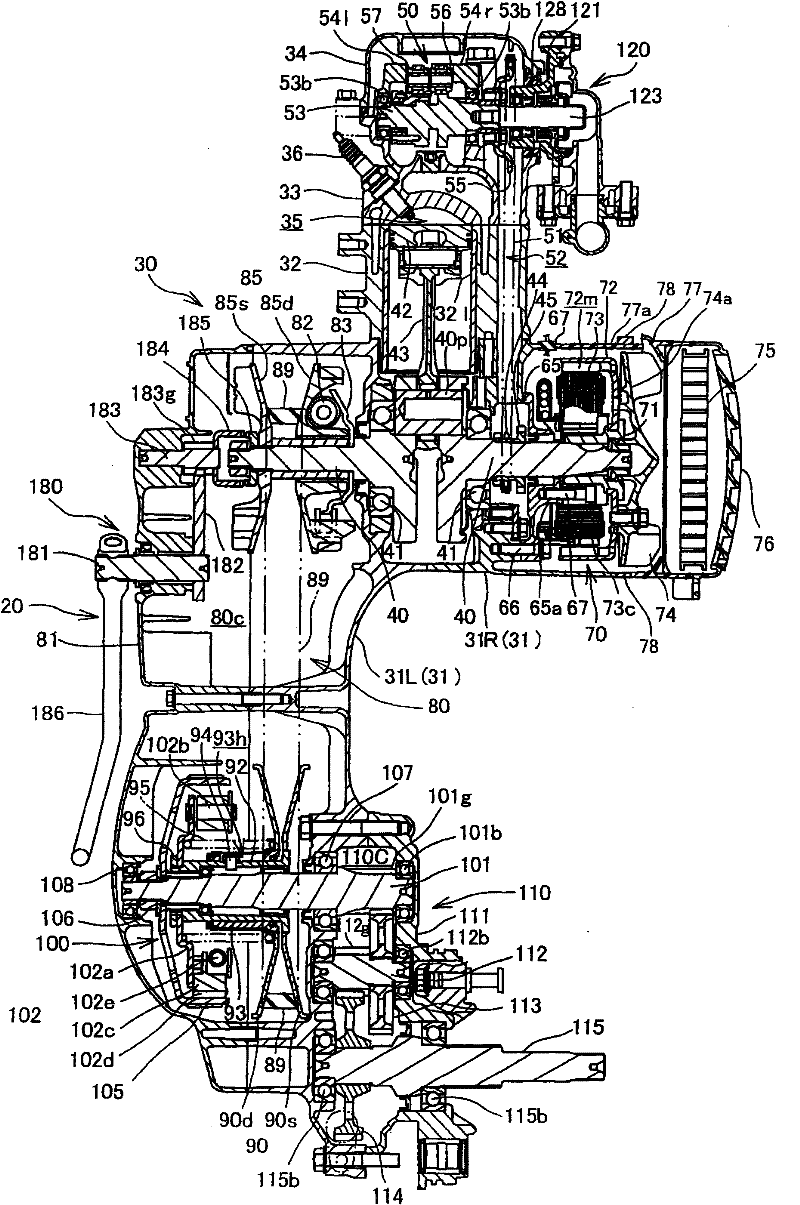

[0042] Below, based on Figure 1 to Figure 11 One embodiment of the present invention will be described.

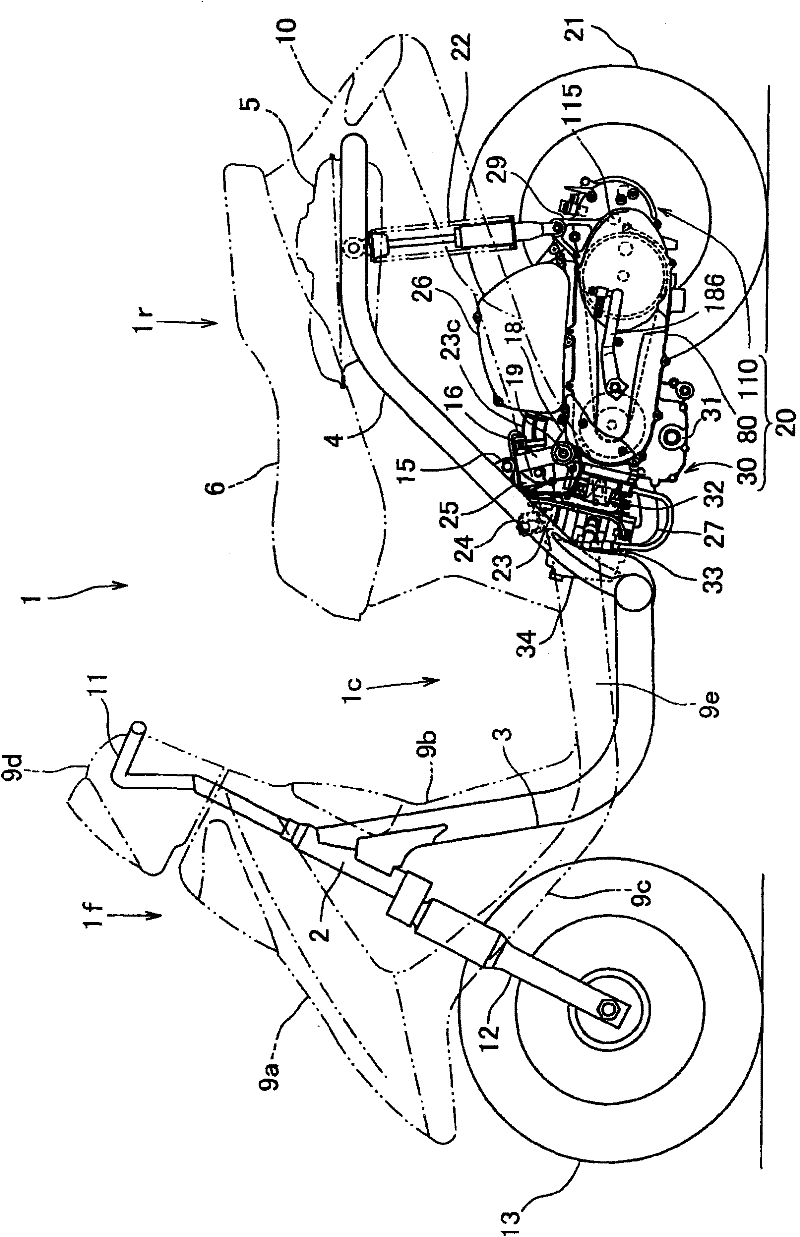

[0043] figure 1 It is a side view of a small motorcycle 1 to which one embodiment of the present invention is applied.

[0044] The front part 1f of the vehicle body and the rear part 1r of the vehicle body are connected via the low floor part 1c, and the frame constituting the skeleton of the vehicle body is generally composed of a downcomer 3 and a main pipe 4 .

[0045] That is, the downpipe 3 extends downward from the head pipe 2 of the vehicle body front part 1f, and the downpipe 3 is bent horizontally at the lower end and extends rearward under the floor portion 1c. 4. The main pipe 4 rises obliquely rearward from the connecting portion, bends horizontally at a predetermined height, and extends rearward.

[0046] A fuel tank 5 and the like are supported by the main pipe 4 , and a seat 6 is disposed above the fuel tank 5 .

[0047] On the other hand, in the vehic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com