Electrophoretic display device and manufacture method thereof

A technology of electrophoretic display and display area, which is applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problems of increased material cost, non-reusable, high proportion of material, etc., and achieve the goal of reducing the increase of material cost and improving the utilization rate of cutting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail in conjunction with the accompanying drawings.

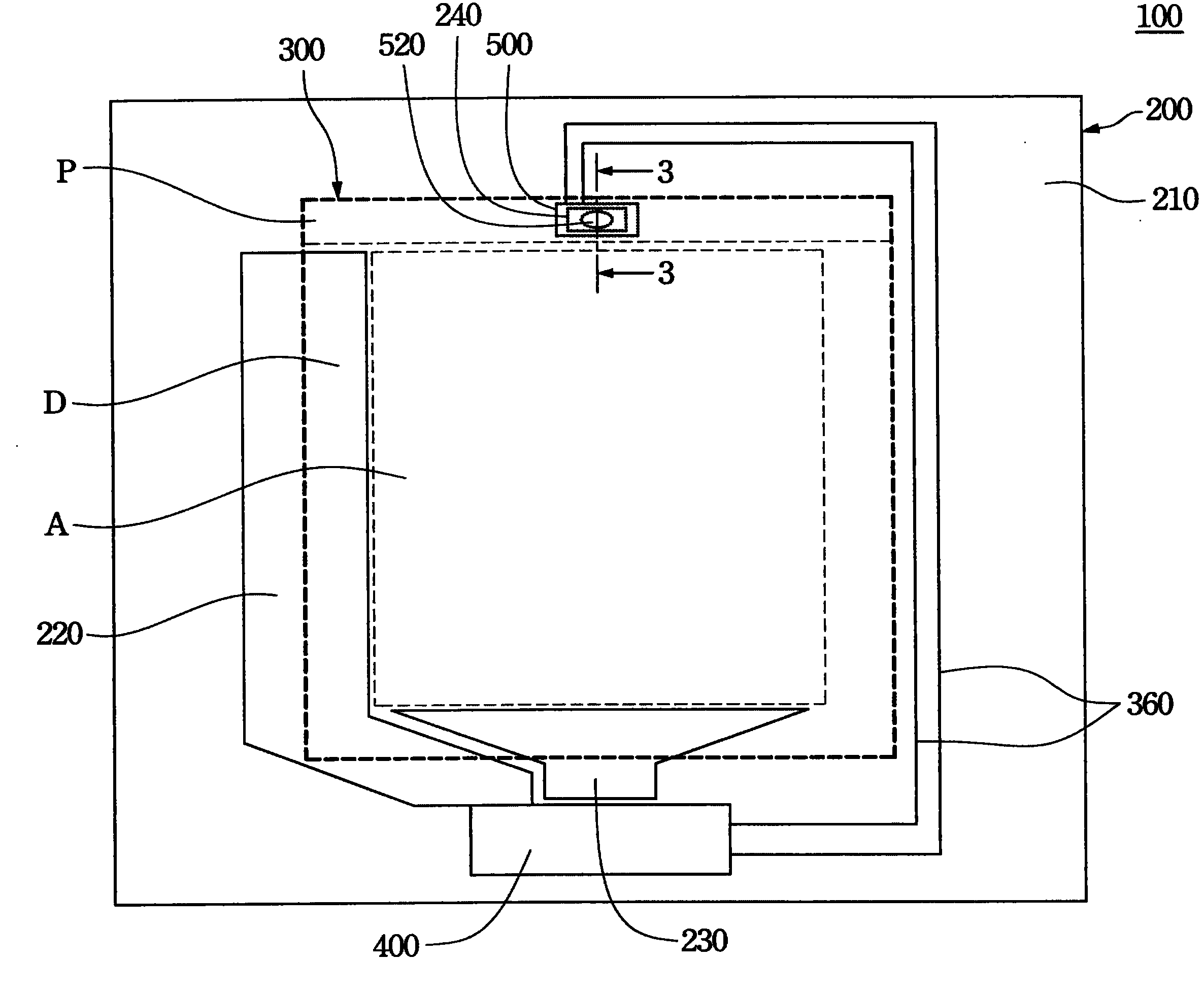

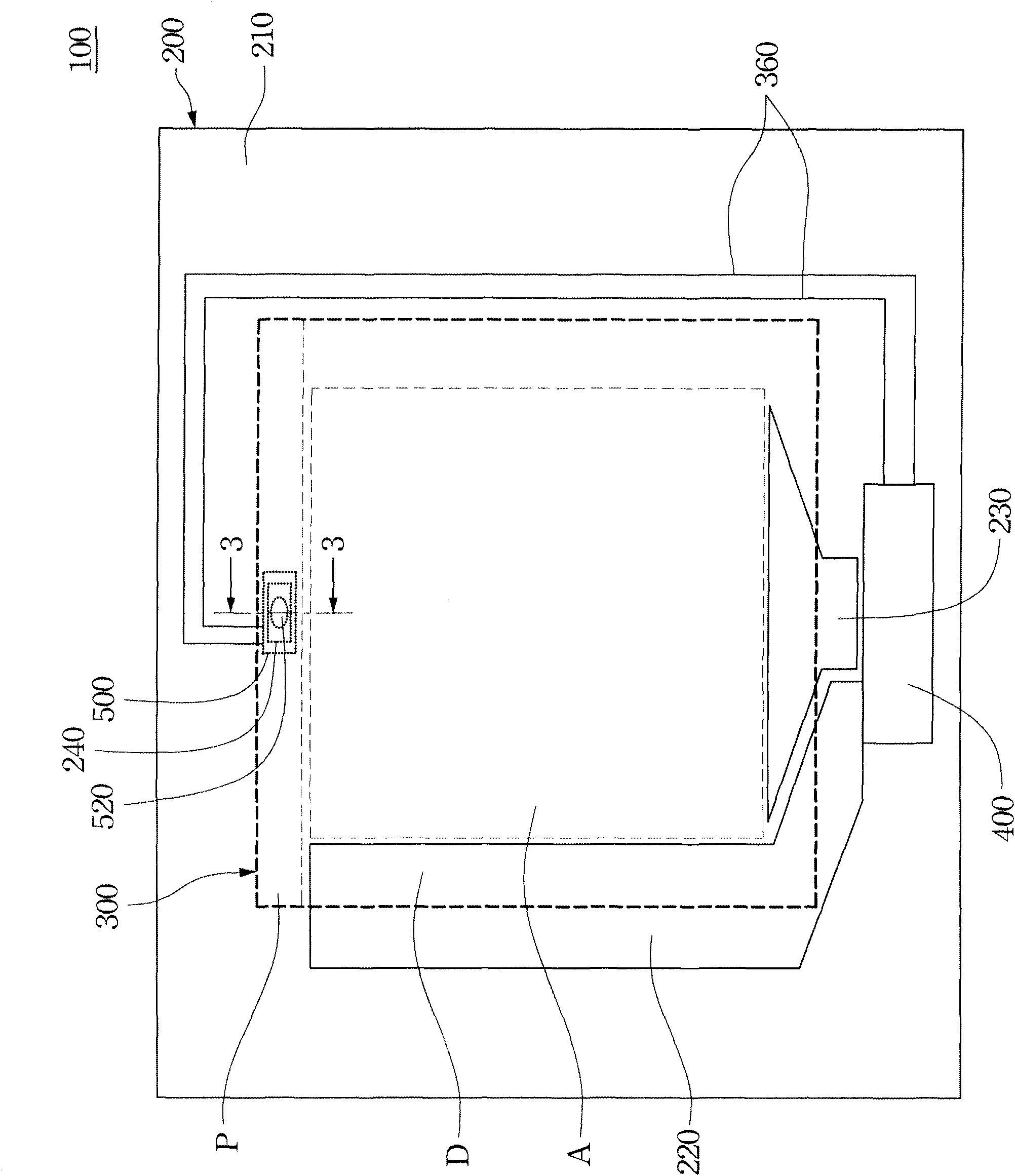

[0034] The invention provides an electrophoretic display device and a manufacturing method thereof. Please refer to FIG. 2A and FIG. 3 . FIG. 2A is a schematic top view of an embodiment of the electrophoretic display device of the present invention. FIG. 3 is a schematic cross-sectional view of line 3-3 in FIG. 2A .

[0035] In this embodiment, the electrophoretic display device 100 includes a driving substrate 200 , an electrophoretic display panel 300 and a control unit 400 (such as a chip, a chipset or a circuit module).

[0036] The driving substrate 200 includes a lower substrate 210 , a gate wiring area 220 , a signal wiring area 230 , a first conductive pad 240 and an electrode area 250 ( FIG. 3 ). The lower substrate 210 can be a plastic substrate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com