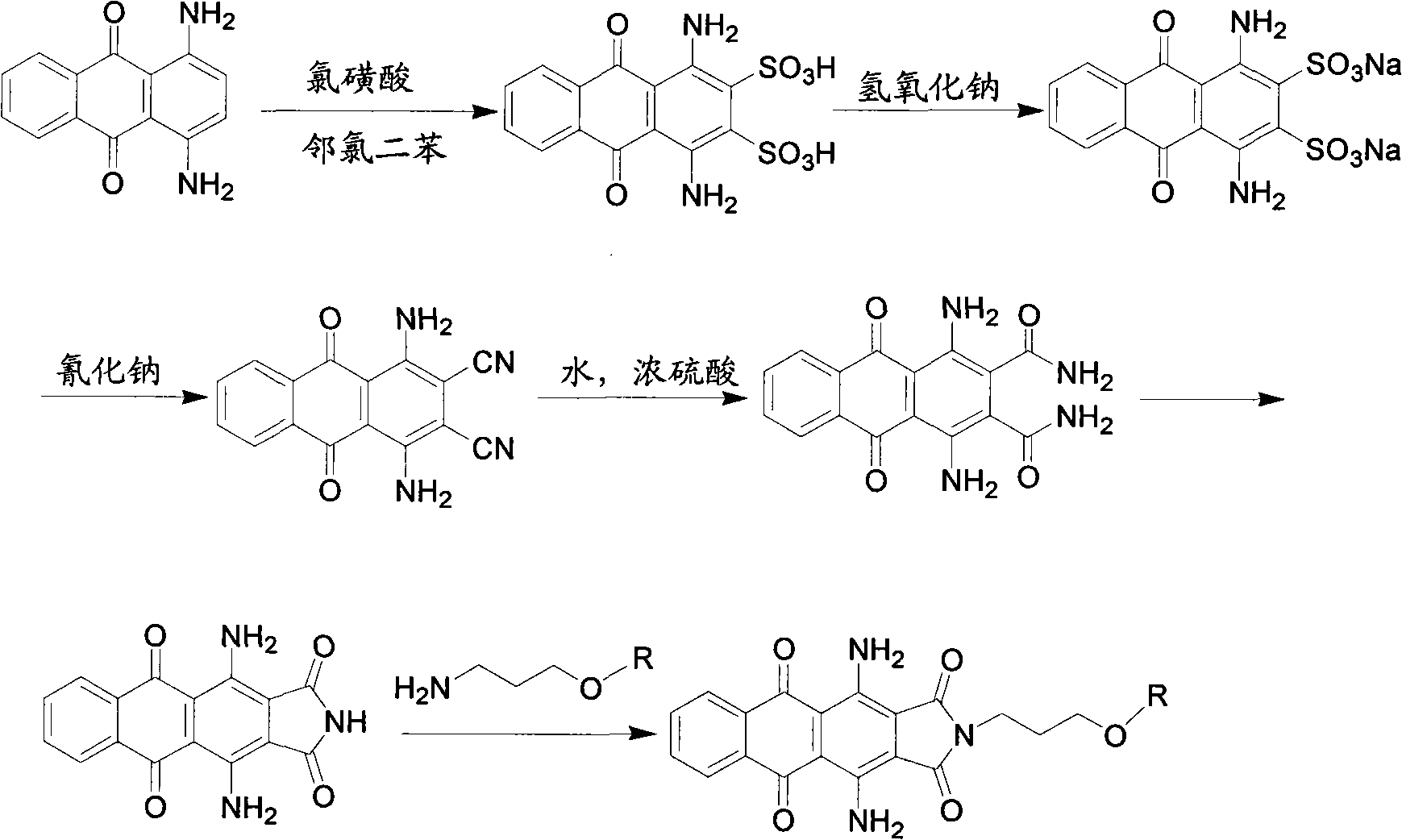

Method for preparing disperse blue 60 and homologues thereof

A technology of homologues and disperse blue, applied in chemical instruments and methods, organic dyes, anthracene dyes, etc., can solve problems such as poor solubility, achieve good quality, high product yield, and solve the effects of steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

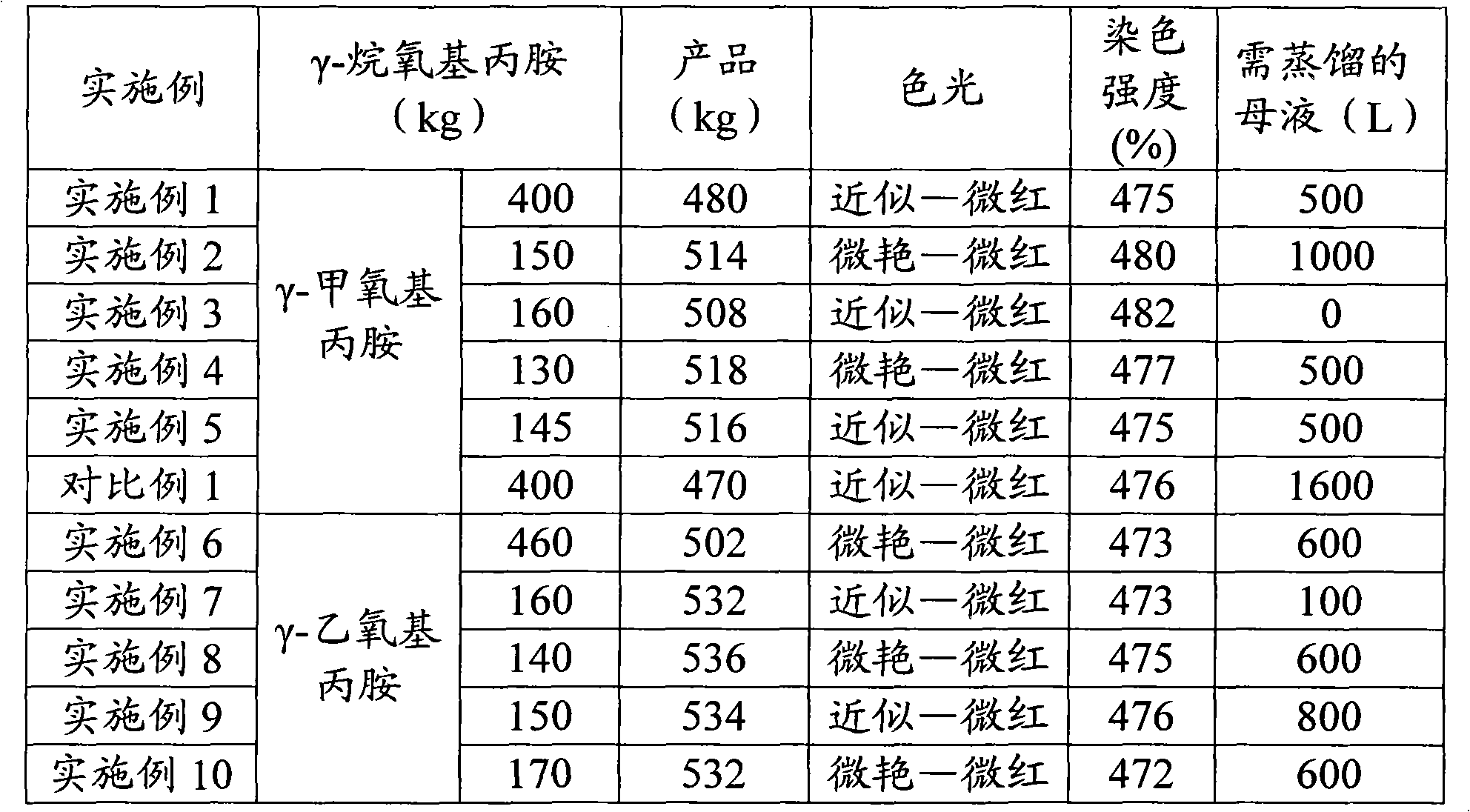

Examples

Embodiment 1

[0025] 1,4-diamino-2,3-dicarboximide anthraquinone is synthesized by a method well known in the art, and the specific steps are: add 2000kg of o-dichlorobenzene into the sulfonation kettle, heat up to 120°C for dehydration , cooled to 50°C and put in 250kg 1,4-diaminoanthraquinone, added dropwise 480kg chlorosulfonic acid at 50-55°C for sulfonation reaction, after adding, slowly raised the temperature to 140°C, and kept the temperature at 140-145°C for 7 hours ; After the sulfonation is completed, cool to 70°C, add 3000L of water to the distillation kettle, pump in the prepared sulfonation material, and then adjust the pH to about 8 with liquid alkali, react and distill, after distillation, filter; the filtrate is transferred to In the cyanidation pot, add 500kg of 30% sodium cyanide aqueous solution, then add anti-staining salt for cyanidation, add dilute sulfuric acid dropwise to control the pH value to 9.0-9.5, and the cyanidation reaction temperature is 98°C; Add sodium bi...

Embodiment 2

[0028] After the enamel kettle of 5000L is put into Example 1 and the condensation reaction is completed, the mother liquor 2000kg is obtained by filtration, and the stirring is started, and the prepared wet product 1,4-diamino-2,3-dicarboximide anthraquinone (reduced dry 450kg), after throwing in, add 150kg of γ-methoxypropylamine that has been prepared, cover the lid of the kettle, stir for half an hour, heat up to 102°C, the reaction pressure is 0.13MPa, keep warm for 6 hours, then cool to 60°C, filter , the mother liquor obtained by filtration was collected in the mother liquor tank, and the filter cake was washed to neutrality to obtain Disperse Blue 60.

Embodiment 3

[0030] Put the enamel kettle of 5000L into Example 2 after the condensation reaction is completed and filter to obtain 1500kg of mother liquor, 500kg of water, start stirring, and add the prepared wet product 1,4-diamino-2,3-dicarboximide anthracene Quinone (dried 450kg), after throwing in, add 160kg of γ-methoxypropylamine that has been prepared, cover the pot, stir for half an hour, heat up to 95°C, and the reaction pressure is 0.11MPa, keep warm for 6 hours, and then cool to 60 °C, filter, and collect the mother liquor obtained by filtration in the mother liquor tank, wash the filter cake with water until neutral, and obtain Disperse Blue 60.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com